Received 16 April 2016; accepted 27 May 2016; published 30 May 2016

1. Introduction

A strong and rapidly growing Moringa oleifera Lamarck (fam. Moringaceae) tree is widely cultivated due to its high adaptability to environmental conditions [1] . It’s considered as one of the most useful trees in the world because almost all parts of this plant can be used as in food, in medicines and for industrial purposes [2] . In many countries, there are huge efforts to spread the use and cultivation of M. oleifera, since it is a significant source of fats, proteins, beta-carotene, vitamin C, iron, potassium, and other nutrients with low toxicity of seeds and leaves [3] . For these reasons, some parts of this plant have drawn much attention and have been studied for its various biological activities, including antiatherosclerotic [4] , immune-boosting [5] , anticardiovascular diseases [6] , antiviral [7] , antioxidant and antimicrobial [8] , anti-inflammatory [9] properties and tumor suppressive effects in skin papillomagenesis, hepatocarcinoma cancer, colon cancer, and myeloma [7] [10] - [12] . The most recent studies on M. olefiera are using the crude protein from the dried and green pod in animal feeding [13] , while no brillient studies have been achieved to M. olefiera seed in human nutrition so far. Although its leaves represent an important source of proteins, the nutritional quality depends on the absolute and relative contents of essential amino acids and its bioavailability after digestion and absorption. Pinto et al. [14] demonstrated that vegetable proteins are less susceptible to in vivo digestion than animal proteins. The low content of sulfur amino acids, compact structure, presence of non-protein components (dietary fiber, tannins, phytic acid) and antiphysiological proteins (protease inhibitors, lectins) can affect digestion. Teixeira et al. [1] found that whole leaf flour contained 28.7% crude protein, 7.1% fat, 10.9% ashes, 44.4% carbohydrate and 3.0 mg 100 g−1 calcium and 103.1 mg 100 g−1 iron. The protein profile revealed levels of 3.1% albumin, 0.3% globulins, 2.2% prolamin, 3.5% glutelin and 70.1% insoluble proteins. Otherwise, the most recent investigations reported that a flocculating protein (6.5 kDa, IEP pH 10) from the seeds of M. oleifera was isolated and purified. Amino acid analysis and sequencing showed high contents of glutamine, arginine and proline, and a total of 60 residues [15] - [18] . Moreover, Mo-CBP3 is an antifungal protein produced by M. oleifera which has been investigated as potential candidate for developing transgenic crops [14] . Freire et al. [17] found that Mo-CBP3 is a chitin-binding protein that inhibits the germination and mycelial growth of phytopathogenic fungi. This protein is highly thermostable and resistant to pH changes, and therefore may be useful in the development of new antifungal drugs.

The oil concentration in moringa seed was ranged from 25.8% to 31.2% [19] . The physicochemical properties and oxidative stability of extracted oil from seeds of M. oleifera recorded that cold pressed oil contains high levels of β-sitosterol (up to 50.07%), stigmasterol (up to 17.27%), and campesterol (up to 15.13%). Moreover, α, γ, and σ-tocopherols were detected up to levels of 105.0, 39.54, and 77.60 mg/kg of oil, respectively [19] . The fatty acids profile of M. oleifera oil was found to contain high levels of unsaturated fatty acids, especially oleic (up to 75.39%). The dominant saturated acids were behenic up to 6.73% and palmitic up to 6.04% [19] [20] . The high oleic acid content also provides good stability to M. oleifera seed oil. It had a good thermal stability. Surly, the oxidative stability and frying stability of cold pressed M. oleifera Jaffna variety seed oil was better than commercial raw and refined groundnut oils, respectively. Based on the present findings, M. oleifera Jaffna variety seed oil has shown enough promise to be considered as more stable and healthy substitute for commercial groundnut oil as a cooking and frying medium [21] - [24] . Moreover, nine fatty acids were detected where oleic acid was found in the largest amount, followed by palmitic acid and behenic acid. The crude, neutralized, and degummed oils showed high primary oxidation stability, while the bleached oil had a low incidence of secondary oxidation [21] [25] . Cold pressed (CP) and hexane extracted (HE) moringa seed oils were evaluated for their physicochemical and stability characteristics. The iodine value, saponification value and unsaponifiable matter of CP and HE were found to be 67.8 and 68.5 g I2 100 g−1 oil, 190.4 and 191.2 mg KOH g−1 oil and 0.59 and 0.65%, respectively. The total tocopherols of CP and HE were found to be 95.5 and 90.2 mg・Kg−1. The fatty acid composition of CP and HE showed oleic acid as the major fatty acid (78% - 79%). The oxidative, thermal and frying stabilities of CP were compared with commercial raw and refined groundnut oil (GNO). The CP was of adequate thermal stability and better oxidative stability as it showed 79% lesser peroxide formation than GNO. The frying stability of CP was better as it showed lower increase in free fatty acid (28%), peroxide value (10 meq O2 Kg−1) and color (25%) than RGNO (48%, 22 meq O2 kg−1 and 52% respectively) after frying [26] . Recently in Egypt and due to its use into the herbal tea, the current study had focused on characterization of M. oleifera seeds and their extracted oil for their bioactive compounds especially with antioxidant and antimicrobial activities. Considering its advantages, the scientific assessment of its potential uses as a new product in Egypt markets as an alternative nutritional source is convenient and necessary. Therefore, the objectives of current work were to determine the physicochemical properties of M. oleifera seeds cultivated at different regions in Egypt regarding the chemical, phytochemical composition, antioxidant capacity, amino acids profile of extracted seeds. Moreover, the physicochemical properties and fatty acids composition of moringa seeds edible oil have been investigated to assess their nutritional aspects.

2. Materials and Methods

2.1. Moringa Seeds and Edible Oil Preparation

The seeds of M. oleifera were collected from trees of the main three different cultivation area located in [Asuit, Ismalia, and Monofya Governorates, Egypt]. The same age seeds collected from same age trees were dried at 35˚C - 40˚C in van air circulating oven till dryness. The dried seeds were crushed in a knife mill to obtain homogenes seed particles. Subsequently, the crused seeds were mechanically pressed to extract the edible oil then filtered and kept in dark bottles with airtight lids under cooling temperature until being used. Dried raw seeds, extracted oil and extracted pomace cake (EPC) was collected and kept under cooling for analysis.

2.2. Proximate Chemical Composition and Minerals Content

The dried seeds were subjected to the chemical analysis (moisture, crude protein, crude lipids, ash, crude fibre according to methods of A.O.A.C. [27] accordingly, the caloric value had been calculated relatively according to obtained results of proximate chemical composition A.O.A.C. [27] . However, the available carbohydrates content was determined by defference according to Merrill and Watt [28] . The minerals content includingsodium, potassium, and calcium was determined in EPC using flame photometry while magnesium, iron, copper, manganese, zinc and selenium contents were determined by atomic absorption spectroscopy according to A.O.A.C. [27] . A standard colorimetric method was applied for phosphorus as mentioned by Borah et al. [29] .

2.3. TPC Determination

Ten g of re-defatted EPC dried powder was mixed with 50 ml of 70% methanol (v/v). The mixes were shaken vigorously in a dark bottle for 100 min at 100 rpm. After centrifugation at 3225× g for 10 min, the supernatant was collected and the residue was re-extracted twice with 25 ml 70% methanol for total phenolic content and antioxidant activity determination. To avoid oxidation, all extracts were stored in the dark at −20˚C and analyses were performed within 48 h. The TPC of Moringa EPC powder was determined according to Folin-Ciocalteu spectrophotometric method [30] . The measurements were compared to a standard curve of prepared gallic acid (GA) solution, and the total phenolic content was expressed as milligrams of gallic acid equivalents (GAE) per gram of dried sample (mg of GAE g−1 dw).

2.4. Antioxidant Activity Determination

2.4.1. The DPPH Scavenging Activity Assay

The radical scavenging activity using DPPH reagent (1,1-diphenyl-2-picrylhydrazyl) for moringa EPC extracts have been carried out using modified method by Barakat and Rohn [30] . Each EPC extract (0.1 ml) was added to 2.9 ml of 6 × 10−5 molmethanolic solution of DPPH. The absorbance at 517 nm was measured after the solution had been allowed to stand in the dark for 60 min. The Trolox calibration curve was plotted as a function of the percentage of DPPH radical scavenging activity. The final results were expressed as micromoles of Trolox equivalents (TE) per gram (μmol TE g−1 dw).

2.4.2. ABTS Scavenging Activity Assay

The radical scavenging activity (RSA) of the different moringa EPC against the stable ABTS radical cation was measured using the method of Lu et al. [31] . A Trolox calibration curve was plotted as a function of the percentage of ABTS radical cation scavenging activity. The final results were expressed as micromoles of Trolox equivalents (TE) per gram of dried EPC (µmol of TE g−1 dw).

2.5. Phytochemicals Analysis

2.5.1. Total Carotenoids Determination

According to Yuan et al. [32] ; 5 g of each defatted moringa EPC were extracted with a mixture of acetone and petroleum ether (1:1, v/v) repeatedly using the mortar and pestle until a colorless residue was obtained. The upper phase was collected and combined with crude extracts after washed for several times with water. The extracts were made up to a known volume with petroleum ether. Total carotenoids content was determined by recording the absorbance at 451 nm with a spectrophotometer. Total carotenoids were calculated and expressed as mg g−1 dw.

2.5.2. Flavonoids and Flavonols Determination

The total flavonoids content of moringa EPC were determined according to the method of Mohdaly et al. [33] . A 0.5 ml aliquot of 2% AlCl3 ethanolic solution was added to 0.5 ml of the extracts and mixed well. After keeping for 1 h at room temperature, the absorbance at 420 nm was measured. A yellow color indicates the presence of flavonoids. The total flavonoids content were expressed as mg quercetin equivalent (QE) per 100 gdw. The total flavonols content were determined according to Kumaran and Karunakaran [34] . A 0.6 ml aliquot of 2% AlCl3 ethanolic solution was added to 0.6 ml of each extract and 0.8 ml of a 5% aqueous sodium acetate solution were added. After mixing and keeping for 2.5 h at room temperature, the absorbance at 440 nm was measured. Total flavonols content were expressed as mg quercetin equivalent (QE) per 100 g dw.

2.6. Amino Acids Determination

The amino acids profile was carried out on the precipitated protein from defatted moringa EPC after hydrolysis by 6.0 N HCl for 24 h at 110˚C in evacuated ampoules. Quantitative determination of amino acids were carried out by Biochrome 30 instruction manual (Analyzer used), 2005. EZ chrome manual (software for data collection and processing), 2004 according to A.O.A.C. [35] .

2.7. Determination of the Physicochemical Parameters and Fatty Acids Composition of Moringa Seeds Oil

2.7.1. Determination of Physicochemical Properties

Physicochemical properties of extracted oils from moringa seeds oil were determined. Specific gravity and refractive index were determined according to A.O.A.C. [37] . However, acid and peroxide values, iodine and saponification numbers and nonsaponifiable matters were determined according to methods described by Habib [36] .

2.7.2. Determination of Fatty Acid Composition

Derivatization procedure: Total fatty acid fractions were methylated according to Aldai, Osoro [37] . The methyl esters of fatty acids (FAs) obtained from moringa seeds oil were analyzed with a gas liquid chromatography equipped with a dual flame ionization detector. For methylation of free FAs, samples were dried under N2 at 40˚C then dissolved in 1 ml of methanol: toluene (2:1, v/v) and vortexed for 5 min. At this stage, methylation reagent was added in molar excess using 120 µl n-hexane and the reaction proceeded at 40˚C for 10 min in opened tubes. The samples were dried again under gentle stream of N2 at 40˚C for approximately 20 min. Finally, each sample was reconstituted in 2 ml of n-hexane (with 50 ppm of BHT), centrifuged at 20.000× g for 5 min at 7˚C then transferred into vials and kept at −20˚C. Before GLC injection, samples were diluted in 1 µl n-hexane then injected into GLC column and run under an optimized temperature program with optimized gas flow rate.

GLC equipment and program: Varian Star CX3400 GLC (Varian, Spain) equipped with a FID detector, an automatic sample injector (SPI) in one column mode and a Chrompak CP-SIL 88 for FA methyl esters (FAMEs) (WCOT FUSEDSILICA 100 m × 0.25 mmd 0.2 µm film thickness) with retention gap (FUSED SILICA- TUBING 4 m × 0.25 mm i.e., Methyl deactivated) was used. It’s used as the carrier gas with a column head pressure of 355 kPa and a flow rate of approximately 2 ml・min−1 measured at 100˚C. The GLC conditions were as follows: (100˚C, at 2˚C min−1 to 170˚C, hold for 15 min, at 0.5˚C min−1 to 180˚C, at 10˚C min−1 to 200˚C and hold for 10 min at 2˚C min−1 to 230˚C then hold for 10 min); injection temperature was 250˚C; detector temperature was 300˚C. Results were evaluated with a conventional integrator program (Saturn GC Workstation Software ver., 5.51).

2.8. Statistical Analysis

The statistical analysis was carried out using SPSS program with multi-function utility regarding to the experimental design under significance level of 0.05 for the whole results. Multiple comparisons applying LSD was carried out according to Steel et al. [38] .

3. Results and Discussion

3.1. Proximate Chemical Composition of M. oleifera Seeds

Directly after the appropriate samples have been collected and similarly dried and milled then were subjected to the analysis. The proximate chemical composition of moringa seeds comes from cultivated plants at different regions were carried out and the data were illustrated in Table 1. It could be observed that there are no significant differences (p > 0.05) among dried moringa seeds in their moisture, protein, lipids and available carbohydrates contents. On the contrary, there are significant difference was observed (p < 0.05) among the analysed moringa seeds in ash and fiber contents. Interestingly, all moringa seeds seem to be a good source of crude protein and lipids. The protein, lipid, ash, fiber and total carbohydrate contents were in range of 34.51% - 36.5%, 28.62% - 30.06%, 4.22% - 5.06%, 10.92% - 12.16% and 19.00% - 20.29%, respectively. The data indicate that ash and crude fiber contents were significantly higher in M. Oraby than both M. Asuit and M. Monofya. It is worth mentioning that higher protein, lipid and available carbohydrates contents exude relevant caloric value around 450.36 - 451.32 kcal 100 g−1 for dried moringa seeds with no observed significant difference (p > 0.05).

The obtained results are closely pertinent to observed results by [23] [39] - [41] . However, the variation of obtained results in the chemical composition might be related to samples collection, preparation and cultivation conditions [1] [39] [42] .

3.2. Minerals Content of M. oleifera EPC

The minerals content as macro-elements such as (sodium, potassium, calcium, phosphorus and magnesium) and micro-elements such as (iron, copper, manganese, zinc and Selenium) in mg 100 g−1 of M. oleifera EPC are given in Table 2. At the first glans, no selenium content had been detected in all analyzed samples. However, sodium content was ranged from 1353.5 mg 100 g−1 dw in M. Oraby to 1475.3 mg 100 g−1 in M. Asuit. A significant difference (p < 0.05) was found among all moringa EPC. Potassium content was 1045.2, 1143.8 and 1278.7 mg 100 g−1 dw in M. Monofya, M. Oraby and M. Asuit, respectively. Calcium content recorded 254.2, 353.7 and 478.6 mg 100 g−1 dw for M. Asuit, M. Oraby and M. Monofya, respectively. M. Oraby exhibited significantly

![]()

Table 1. Proximate chemical composition of M. oleifera seeds (mean ± SE).

dw: dry weight, fw: fresh weight.

![]()

Table 2. Minerals content of M. oleifera PEC (mean ± SE).

dw: dry weight, ND: not detected.

higher phosphorus content than M. Monofya. Obviously, M. Monofya exhibited significantly higher magnesium content than either M. Oraby or M. Asuit. In the same context, M. Monofya demonstrated significantly higher iron and zinc contents than both M. Oraby and M. Asuit. In contrary, M. Oraby recorded the highest manganese content among all moringa samples. There is no significant difference had been observed between all moringa samples in copper content. The obtained results reflect that dried moringa seeds cultivated at different regions in Egypt are considered as a rich source of dietary minerals. Comparing the current results with the reviewed minerals resulted it could be illustrated that current results are in harmony with previously mentioned [23] [39] - [41] . However, some few minerals are exhibit higher or lower results than reviewed which reflect the effect of cultivation and environmental conditions as confirmed by [1] [39] [42] .

3.3. Phytochemicals and Antioxidant Capacity of M. oleifera EPC

Data in Table 3 shows the content of TPC [mg g−1 dw] and antioxidant activity [μmol TE g−1 dw] of M. oleifera seeds at different regions in Egypt. Moreover, the phytochemicals such as chlorophylls a & b, carotenoids, flavonoids, and flavonols of various moringa EPC samples have been investigated and data are given in the same table. TPC content and antioxidant activity of M. oleifera EPC were ranged from 16.9 - 18.5 mg GAE g−1 dw. The evolution of DPPH and ABTS radical scavenging activity of various moringa was assayed using the common DPPH and ABTS assays and results are referred to Trolox equivalent g−1 [μmol TE g−1] and given in Table 3. The antioxidant capacity of determined TPC showed a positive relation depends on the initial content being as high TPC high antioxidant response had been remarked. The result of antioxidants activity (DPPH scavenging activity) noticed no significant difference (p < 0.05) among the three moringa samples which was in a range of 0.17 - 0.28 μmol TE g−1 dw. In the same context, result of antioxidants activity (ABTS scavenging activity) recorded also no significant difference (p < 0.05) among the three moringa samples which was in a range of 4.19 - 6.29 μmol TE g−1 dw. The obtained results are in accordance with [43] [44] . The chlorophyll a [mg g−1 dw], chlorophyll b [mg g−1 dw], carotenoids [mg g−1 dw], flavonoids and flavonols [mg QE g−1 dw] contents were ranged from 0.93 to 1.78, 4.89 to 8.41, 13.53 to 19.56, 3.30 to 5.40 and 2.30 to 4.10, respectively (Table 3). The obtained results are in agreement with [39] [44] - [46] . Regarding to the phytochemicals contents, there was no significant differences (p > 0.05) among the three moringa seeds as they collected carefully from the same part of the trees and from the same harvest even they were dried under the same conditions. These results are a good observation to overview the main differences between M. oleifera cultivated at different regions in Egypt.

![]()

Table 3. Total phenolic compounds and antioxidant activity, chlorophyll a & b, flavonoids and flavonols of M. oleifera defatted seeds cultivated at different regions in Egypt (mean ± SE).

dw: dry weight, *: BPPH radical scavenging activity (BPPH-RSA), **: ABTS radical scavenging activity (ABTS-RSA).

3.4. Amino Acid Composition of M. oleifera Protein

Surely, amino acid compositional data are only the first in the nutritional assessment of any food protein. The amino acids composition for isolated protein from of M. oleifera is given in Table 4. Obtained data showed that, fifteen amino acids were identified. Obviously, the individual EAAs recorded higher contents than EAAs in referenced hen’s egg protein except Lysine in all moringa seeds protein. Leucine remarked to be the highest EAA in all moringa EPC protein while, Lysine recorded the lowest amino acid. The total EAAs found to be in a double fold in moringa EPC protein when compared to hen’s egg protein. Likewise, the individual NEAAs recorded higher contents than NEAAs in referenced hen’s egg protein. Glutamic and proline acids were presented in all moringa protein in a sensible amount being ~4 fold more. However, total NEAAs found to be ~4 fold in moringa seed protein when compared to hen’s egg protein. Total AA showed in triple amount in moringa protein when compared to hen’s egg (Table 4). Data in Table 5 illustrate the nutritional evaluation of moringa protein. The amount of TEAAs was ranged from 29.74 in M. Asuit to 30.96 g 16 g N in M. Monofya which lower content than higher egg’ protein according to FAO (1970).

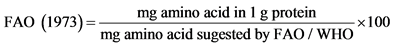

Conversely, TNEAAs was ranged from 62.80 to 63.29 g 16 g N which exhibit higher content than egg’ protein according to FAO (1970). The EAA:NEAA ratio, EAA:Protein ratio, EAA:Total AA ratio and EAAI% demonstrated that moringa proteins are lower than egg’ proteins according to FAO (1970) (Table 5). As recommended by FAO and WHO, there are two main categories being very important for determining the protein quality, one of them depends on calculating the individual AAs score and comparing them to hen’s egg as a standard protein. Screening the all calculated values of moringa proteins, obtained results showed to be very close to the standard values of egg protein. Lysine score being to be in a lower value while Histidine score comes in higher value when compared to egg protein, Table 6. Data in Table 7 shows the certain AAs of moringa protein compared to FAO pattern (mg g−1 protein). The certain AAs of moringa protein were (Lysine, Lysine and Lysine), (Therionine, Tyrosine and Therionine) and (Tyrosine, Therionine and Tyrosine) for first, second and third limiting AA of M. Asuit, M. Oraby and M. Monofya, respectively. These results were more or less in agreement with mentioned previously [14] [15] [17] [39] [47] [48] .

However, a few research data are available regarding to utilization of moringa protein, even it was available a difference might be found regarding the variation of environment, cultivation and sampling condition could influenced the results. Furthermore, moringa protein may have potential food applications.

3.5. Physicochemical Properties of M. oleifera Edible Oil

Not only the physiochemical parameters of moringa seeds oil was measured, but also they compared with soybean, cotton seeds as well as virgin olive oils as edible oils, then data were presented in Table 8. The acid value of moringa oil was ranged from 0.29 mg g−1 in M. Asuit to 0.37 in M. Monofya. However, the recorded values than acid value of all extracted oil were in under the maximum level of allowed acid number when compared to

![]()

Table 4. Amino acid composition of moringa seeds protein cultivated at three deferent regions in Egypt (mg 100 g−1 dw) comparing with standard protein and amino acids scores.

■: Essential amino acids; ■■: Non-essential amino acid.

![]()

Table 5. The nutritional evaluation of moringa seeds protein cultivated at three deferent regions in Egypt.

EAA: NEAA: Ratio of essential amino acids to nonessential amino acid. EAA: Protein Ratio: Ratio of essential amino acids to 100 g protein. NEAA: Total AA Ratio: Ratio of essential amino acids to total amino acid. EAAI %: Essential amino acids index according to FAO.

Amino acid score according to .

.

![]()

Table 7. The certain amino acids in moringa protein compared to FAO pattern mg・g−1 protein.

*According to FAO/WHO AD HOC Committee (FAO, 1973). Amino acid score according to  . Bold highlighted preferred that the lowest percentage compared to FAO pattern.

. Bold highlighted preferred that the lowest percentage compared to FAO pattern.

![]()

Table 8. Physicochemical properties of M. oleifera edible oil extracted from moringa seeds cultivated at different regions in Egypt (mean ± SE).

The saponification number of moringa oil was ranged from 171.7 to 178.3 mg KOH g−1. M. Monofya oil was significantly higher than both moringa oils. The physiochemical characteristics of moringa oils are resembles more or less to all referenced oils. Thus, moringa oils can be used as edible oils after biological investigation being concerned. These results are in agreement with the published results by [19] [21] [22] [25] [26] [49] [50] .

3.6. Fatty Acids Composition of M. oleifera Edible Oil

In order to examine the lipid composition, fatty acids fractionations of M. oleifera edible oils of three cultivation region in Egypt was done and data were illustrated in Table 9. Obtained data observed that eleven fatty acids have been identified. Clearly, the unsaturated fatty acids (USFA) contents of M. oleifera edible oils were 77.14%, 84.98% and 78.99% for M. Asuit, M. Oraby and M. Monofya, respectively. Nonetheless, the percentage of saturated fatty acids (SFA) in M. oleifera edible oils recorded 22.83%, 15.00% and 20.98 % for M. Asuit, M. Oraby and M. Monofya, respectively. Indeed, in all M. oleifera edible oils palmitic and stearic acids were the predominant SFA. In addition, the value of palmitic acid in M. oleifera edible oils was ranged from 5.66% - 6.09%. On the contrary, theoleic acid was the major USFAin all M. oleifera edible oils which ranged from 73.30% - 79.58%.

Furthermore, oleic acid recorded the highest USFA in M. Oraby to be 79.58%. Otherwise, stearic acid scored the highest SFA in M. Asuit to be 7.94%. For the best of our knowledge and from parallel comparison of M. oleifera oils with cotton seeds, soy bean and olive virgin edible oils, the M. oleifera recorded lower palmitic acid and higher stearic, arachidic and behenic acids than edible oils and can be considered as one of the richest source of oleic acid with considerable higher ratio of USFA/AFA than found in cotton seeds oil, olive and soybean oils (Table 9). Undoubtedly, the possibility of using the M. oleifera oils for supporting or mixed with other oils could be a principle of M. oleifera waste valorization. These results are agreement with the previous studies [19] [22] [24] - [26] [50] .

4. Conclusion

Data obtained in present study could be useful for determining the chemical characteristics, minerals content and phytochemicals of moringa seeds which came from the main cultivation region in Egypt. Phytochemicals and their antioxidant exhibited promising potential applications in food processing industries. The amino acids content demonstrated a high potential application of extracted seeds cake in human and animal nutrition being the highly nutrition value of its protein. Physicochemical properties of moringa seeds oil recorded that moringa seeds oil had a promising potential application in nutrition aspects. The higher content of unsaturated fatty acids may present a healthy impact of moringa seeds oil in human nutrition.

![]()

Table 9. Fatty acids composition of M. oleifera edible oil by GLC analysis.

*Results according to Egyptian Standards [51] , Egyptian Standards [52] , Egyptian Standards [53] .

Acknowledgements

The authors are very glad to acknowledge Moringa Misr Company, for providing different samples and technical assistance during harvesting and drying of the M. oleifera seeds insuring the long experience of this company in Moringa production.

NOTES

![]()

*Corresponding author.