Investigation of a Modified Cobalt-Free Alloy for Nuclear Application ()

1. Introduction

Attributing to increasing the use of radioactive sources in different fields such as medicine, tomography, and nuclear research applications, the researchers have focused on studying the photon interactions with matter (attenuation coefficients) as radiation is part of our life. In this work, the author prepared Cobalt-free alloy by electro slag remelting technique, and then mass attenuation coefficient, half value layer and effective atomic number had been determined at photon energies 235 - 2700 keV by using different point radioactive sources (133Ba, 137Cs, 60Co and 232Th). The results showed that the calculated and measured values were in good agreement.

2. Experimental Procedure

The cobalt-free steel sample was prepared in the steel Technology Department, CMRDI, Egypt, using pilot plant induction furnace electro slag remelting technique (ESR). The produced steels were hot forged followed by air cooling. The hot forged steels were subjected to solution treatment (820˚C―for 1 hour), with the aging process (480˚C―for 2 hours) [1] -[5] .

The mass attenuation coefficient of gamma radiation was measured with a narrow beam array using gamma spectroscopy technique in the Physics Department, Faculty of Science, Ain Shams University, Egypt. The arrangement of the device consists of hyper pure germanium (HPGe) detector with relative efficiency ~30% relative to a 3” X 3” NaI (Tl) detector connected to multichannel pulse height analyzer.

The samples were radiated by photons emitted from 60Co, 133Ba, 137Cs and 232Th radioactive point sources in the range (238 to 2614 keV). The attenuation properties of the 2614 keV gamma line are of special importance in the reactor design circumstances.

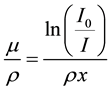

The mass attenuation coefficients have been evaluated by the relation described by [6] -[10]

(1)

(1)

where I0 is the initial photon density, I is the photon density that penetrates the alloy distance x and µ is the linear attenuation coefficient. Also tenth value layer can be calculated by:

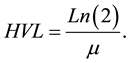

(2)

(2)

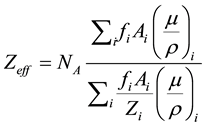

The effective atomic number Zeff of the steel alloys consisting of different elements is based on the determination of total attenuation cross section for γ ray interactions and it can be obtained by the following formula [11] [12] :

(3)

(3)

where NA is the Avogadro’s constant, Zi is the atomic number of the ith element; Ai and fi are atomic weights (in gram) and number of atoms of element i relative to total number of atoms in the alloy respectively.

The chemical compositions of the cobalt-free alloy are presented in Table 1.

3. Results and Discussions

Total linear attenuation coefficient and half value layer for different energies have been measured at photon energies from 0.2 to 2.7 MeV.

The values of the linear attenuation coefficients µ for the investigated alloy at different energies as a function of thickness are shown in Figure 1.

It is shown that the linear attenuation coefficient is inversely proportional to the photon energy from 200 to 1100 keV, then it smoothly decreases with a less rate than in the low energy region.

The transmission rate is an important parameter for testing the shielding material. Figure 2 shows the transmission rate as a function of thickness at specified energies. Also the half value layers are shown in the graphs for each energy line. It is clear from that figure that the larger thickness of the material is needed for stopping the high energy.

The theoretical and experimental values of the total mass attenuation coefficient are presented in Figure 3. The correlation theory is used to confirm the linearity of theoretical and experimental values with a correlation coefficient (R2) about 0.97. It can be noted that the calculated and measured values are in good agreement.

![]()

Table 1. Chemical composition of the investigated alloy.

![]()

Figure 1. The linear attenuation coefficient versus the photon energy.

![]()

Figure 2. The percentage transmission for the new alloy as a function of thickness.

The effective atomic numbers Zeff at photon energies from 0.2 to 3.0 MeV have been calculated for the steel alloy and the results have been displayed in Figure 4. It can be seen from this figure that the effective atomic number decreases with energy increase from (0.2 to 1.0 MeV), and then it slightly increases for higher energies.

4. Conclusion

New shielding cobalt-free steel “0.045%C-12.73%Ni-6.53%Cr-3.2%Mo-0.02%Ti-0.01%V”, was developed by electro slag remelting technique. Mass attenuation coefficients, half value layers and effective atomic numbers of the new alloy have been evaluated. A comparison of the mass attenuation coefficient with the corresponding theoretical one (based on XCOM) has been done and a fair agreement is achieved.

![]()

Figure 3. The total mass attenuation coefficients of the alloy as a function of the energy.

![]()

Figure 4. The effective atomic number as a function of the photon energy.

Acknowledgements

Special thanks to Prof S. El-kameesy and Prof M. Eissa lab groups, for their help.

NOTES

*Corresponding author.