Investigation of the Behavior of a Jet Issued into Two-Layer Density-Stratified Fluid ()

1. Introduction

A fluid consisting of horizontal layers of varying densities is frequently observed in lakes and marshes. Such density-stratified fluid also occasionally appears in liquefied natural gas (LNG) storage tanks. As the density and components of LNG are specific to the producing areas and purification plants, density stratification is produced when one LNG is loaded on top of another LNG in the same tank. After such loading, the density-stratified LNG frequently becomes unstable over time because of temperature and composition variations. When density of the lower LNG becomes smaller than that of the upper one, a sudden mixing, known as rollover, occurs. Rollover generates large amounts of vaporized gases, causing severe damage to the storage tank. Thus, prevention and elimination of stratification is essential for the operation of LNG storage tanks.

Some previous laboratory-based research has focused on density-stratified fluids. Turner [1] heated the tank bottom of a density-stratified fluid and described heat and mass transport across the heat and density boundaries. Baines et al. [2] investigated the mixing produced in a tank by a salt water jet released into water. Bloomfield and Kerr [3] [4] experimentally and theoretically studied the mixing and spreading produced by such a jet. Lin and Linden [5] imposed a turbulent jet on a density-stratified fluid from the tank top to investigate density distribution in the tank. Ansong et al. [6] classified the fluid motion around the interface of a density-stratified fluid when a jet penetrated the interface and further theoretically examined jet height, comparing the corresponding measurements. Papanicolaou and Stamoulis [7] and Srinarayana et al. [8] independently investigated the distance of a jet issued vertically downward from a nozzle mounted above a density-stratified fluid by their experimental works. Baddour et al. [9] measured the height of a jet issued from a tank bottom and clarified that the Boussinesq approximation was applicable to predict the height only when the density ratio of the jet to the ambient fluid was low. Druzhinin and Troitskaya [10] [11] performed the DNS and LES for a jet issued from a round nozzle and examined the effect of the Froude number on the jet behavior.

Mixing LNG by a jet issued from a nozzle mounted on the tank bottom is considered a promising technique to prevent and eliminate stratification in LNG storage tanks. However, useful and applicable knowledge for the LNG tank operation, such as the effects of the jet Reynolds number on the jet behavior and the resultant mixing, is yet to be fully acquired.

The objective of this study, therefore, is to obtain basic knowledge on the jet behavior and mixing phenomena when a jet is issued into a two-layer density-stratified fluid in a tank. The upper and lower fluids are water and a NaCl-water solution, respectively; and the lower fluid is issued vertically upward from a nozzle on the tank bottom. The flow visualization and the measurement of the concentration of the water paint issued with the jet are performed to clarify the effects of the jet Reynolds number, the density difference between the upper and lower fluids, and the fluid thickness.

2. Experimental

2.1. Experimental Setup

Figure 1 shows a schematic of the experimental setup. Initially (t = 0), a two-layer density-stratified fluid is in a static condition in a rectangular tank (600 × 200 × 250 mm3). The upper and lower fluids are water and a NaCl- water solution, respectively. The tank is made of transparent acrylic resin to enable flow visualization. The vertical thicknesses of the upper and lower fluids are z1 and z2, respectively. The mass concentration of the NaCl- water solution is denoted by C0.

A nozzle with a circular cross-section with diameter d of 10 mm and length, 10d, of 100 mm is mounted at the center of the tank bottom. The nozzle outlet is positioned 20 mm above the tank bottom. The origin of the coordinates is set at the center of the nozzle outlet with the x-y plane horizontal and the z-axis vertical. The nozzle centerline coincides with the z-axis. The nozzle is connected with a circular hole in the tank wall near the bottom via a tube, and a pump and flowmeter are installed between the hole and the nozzle.

2.2. Experimental Method and Conditions

At time t ≥ 0, the lower fluid, the NaCl-water solution, is issued vertically upward from the nozzle. The mean velocity at the nozzle outlet section is denoted by U0. The fluid volume in the tank is maintained constant by using pump-driven fluid circulation.

To visualize the jet behavior, a small amount of fluorescent paint (Rhodamine B) is added to the jet. The images in the vertical plane passing through the nozzle centerline are captured by a video camera using a laser light sheet (power: 1 W, wavelength: 532 nm, thickness: 2 mm), as shown in Figure 2. The spatial resolution, framerate, and shutter speed of the camera are 640 × 480 pixels, 200 fps, and 1/200 s, respectively.

To reveal the mixing phenomena, a small amount of white water paint is added to the jet, and the images in the vertical plane are captured by a flow visualization camera. The brightness of the water paint in the image is assumed to be proportional to the concentration Γ of the paint [12] . In order to normalize the Γ value, Γ is set to 1 at the nozzle exit and 0 in regions furthest from the nozzle. This is because the brightness, which is at the maximum at the nozzle exit, decreases with increasing distance from the nozzle. To validate the assumption for the brightness, a preliminary experiment was performed. A dilute paint/water solution was made in an acrylic container and the image on a laser light sheet was acquired by the camera. The brightness for the three kinds of the paint concentration was examined. It was confirmed by the examination that the brightness is nearly proportional to the concentration. The concentration was less than 0.0058 g/L.

The concentration Γ was measured on three vertical lines located between the laser and the jet centerline, as mentioned in the following section. Therefore, the intensity of the laser sheet on the lines was almost uniform, and accordingly the concentration measurement was appropriately conducted.

The jet Reynolds number, Re, is defined by dU0/ν, where ν is the kinematic viscosity of water. Thus, the experimental parameters are Re, the upper fluid thickness (z1), the lower fluid thickness (z2), and the mass concentration of the NaCl-water solution (C0). Table 1 summarizes the experimental conditions.

3. Results and Discussions

3.1. Jet Behavior Relative to Density Interface

The jet behavior relative to the density interface between the upper and lower fluids is classified into three patterns A, B, and C according to the Reynolds number Re and mass concentration of the NaCl-water solution C0.

![]()

Figure 2. Visualization of the vertical cross-section of the flow field.

Figure 3 shows typical examples for C0 = 0.02, where z1 = 40 mm and z2 = 70 mm. The white area representing the fluorescent paint issued from the nozzle reveals the jet. In Pattern A, observed at Re = 95 (Figure 3(a)), the jet reaches the density interface without penetrating it. The top of the jet spreads almost horizontally outward along the interface and thus causes minimal mixing. In Pattern B, observed at Re = 476, the jet penetrates the density interface and the nonaxisymmetric flow structure becomes pronounced, as shown in Figure 3(b). The top of the jet falls back to the interface due to the gravitational effect, as the jet density is greater than the upper fluid density. Thus, the jet does not reach the upper boundary, i.e., the water surface. The fluid descending from the top of the jet spreads horizontally when it again reaches the density interface, which causes the interface to heave. The mixing layer is evident in a region along the interface. In Pattern C, observed at Re = 2378 (Figure 3(c)), the jet penetrating the density interface reaches the upper boundary and spreads significantly in the horizontal direction along the boundary. The horizontal flow along the density interface is also observed, with active mixing between the jet and the upper fluid.

The visualized image was deformed by the density distribution to some extent. But the deformation appeared in quite thin layer along the density interface. Thus, the visualization and the concentration measurement were not substantially affected by the deformation.

Figure 4 shows the pattern map of the jet behavior in the case of z1 = 40 mm and z2 = 70 mm. Pattern A appears only when Re is extremely low. The transition from Pattern A to B is not sensitive to C0, and vice versa. The Re range at which Pattern B appears broadens with increasing C0. Note that an intermediate pattern exists between Patterns B and C when C0 ≥ 0.02, as indicated by open circular symbols. The jet does not always reach the upper water surface but intermittently touches the surface.

When a fluid with density ρ reaches the density interface from the outside, it flows in a horizontal direction along the interface if the condition of ρ1 < ρ < ρ2 is satisfied, where ρ1 and ρ2 are the densities of the upper and lower fluids, respectively [13] . Such flow is recognized as an intrusion of an internal density current. An example of this type of flow can be observed in the temperature-stratified water of a dam reservoir when muddy water mixed with sands flows into the reservoir and reaches the density interface. The horizontal flow along the density interface visualized in Figure 3 corresponds to the intrusion of an internal density current. The intrusion is found to occur when the jet perpendicularly impinges the density interface.

![]() (a) (b) (c)

(a) (b) (c)

Figure 3. Typical behavior of the jet issued into density-stratified fluid (C0 = 0.02, z1 = 40 mm, z2 = 70 mm). (a) Pattern A (Re = 95); (b) Pattern B (Re = 476); (c) Pattern C (Re = 2378).

![]()

Figure 4. Pattern map of jet behavior (z1 = 40 mm, z2 = 70 mm).

To investigate intrusion along the density interface, the intrusion distance rj is defined as shown in Figure 5(a), where rj is the value of the x-coordinate for the outer end of the fluorescent paint. Figure 6 shows the relationship between the nondimensional intrusion distance rj/d and the nondimensional time t* (=tU0/d), where Re = 476, z1 = 40 mm, and z2 = 70 mm. rj/d increases with time. The intrusion distance is known to be proportional to the 5/6 power of time, as the present results confirm. The intrusion velocity is higher at t* ≤ 60. The radial position of the outer edge for the intrusion is less than 3d when t* ≤ 60, and the fluid descending from the top of the jet reaches the interface at r/d ≤ 3 as found in Figure 3(b). Therefore, it is considered that the intrusion is accelerated by such descending fluid.

3.2. Distribution of Concentration of Water Paint Issued with the Jet

The concentration Γ of the water paint issued with the jet from the nozzle changes in the vertical (z) direction, as shown in Figure 7. The changes along the vertical lines at x/d = 1, 3, and 5 are plotted, where C0 = 0.02, z1 = 40 mm, and z2 = 70 mm. The changes at Re = 95 are shown in Figure 7(a). The jet behavior is categorized as Pattern A. The jet reaches the density interface but does not penetrate it, as seen in Figure 3(a). Maximum Γ occurs slightly below the interface (z/d = 5), and is the largest near the jet centerline (x/d = 1), yet lower at x/d = 3

![]() (a) (b)

(a) (b)

Figure 5. Definition of intrusion distance and maximum height of jet. (a) Intrusion distance rj; (b) Maximum heigh of jet hj.

![]()

Figure 6. Time variation of intrusion distance.

![]() (a) (b)

(a) (b)

Figure 7. Distribution of concentration for water paint issued with the jet (C0 = 0.02, z1 = 40 mm, z2 = 70 mm). (a) Re = 95 (Pattern A); (b) Re = 2378 (Pattern C).

and 5. The effect of the jet appears only around the top of the jet near the density interface. Figure 7(b) shows the changes in Γ at Re = 2378. The jet behavior is categorized as Pattern C. The jet penetrating the density interface reaches the upper water surface, as seen in Figure 3(c). The Γ value near the jet centerline (x/d = 1) is high in the broader region above the density interface as well as beneath the upper water surface, even at x/d = 5. This is a product of the fluid flow along the water surface and thus reconfirms active mixing between the jet and the ambient fluid.

Figure 8 displays the distribution of Γ when C0 = 0.01 and 0.03. The jet behavior corresponds to Pattern B. Γ is higher near the jet centerline (x/d = 1), with the maximum value around the density interface. The vertical position at which the maximum Γ value occurs is lower when C0 = 0.03. This is because the jet density is larger. Therefore the maximum height of the jet lowers owing to the larger gravitational effect, as explained later. When C0 = 0.03, the Γ value is extremely low at x/d = 5, which reveals a decrease in the horizontal spread of the jet and a reduction in the mixing.

3.3. Maximum Jet Height

To understand the mixing of a density-stratified fluid by a jet, knowledge of the maximum height of the jet is essential. This study defines the maximum height hj as shown in Figure 5(b), where hj is the value of the y- coordinate for the upper end of the fluorescent paint.

Figure 9 shows the relationship between the nondimensional height hj/(z1 + z2) and Re. The height increases with increasing Re, with the jet finally reaching the upper water surface at hj/(z1 + z2) = 1. The increase in height decreases with increasing C0. As such, the jet velocity must be augmented for the jet to reach the water surface when C0 is higher.

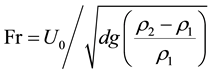

The maximum height of the jet may be governed by the gravitational effect acting on the jet in the upper fluid. The Froude number Fr is defined by the following equation to predict the maximum height.

(1)

(1)

where g is the gravitational acceleration, and ρ1 and ρ2 are the densities of the upper and lower fluids, respectively.

![]() (a) (b)

(a) (b)

Figure 8. Distribution of concentration for water paint issued with the jet (Re = 476, z1 = 40 mm, z2 = 70 mm). (a) C0 = 0.01; (b) C0 = 0.03.

![]()

Figure 9. Relationship between maximum height of jet and Reynolds number.

Figure 10 shows the relationship between the nondimensional height hj/(z1 + z2) and Fr, where the results at 0.01 ≤ C0 ≤ 0.04 are superimposed. When the jet does not reach the upper water surface (hj/(z1 + z2) < 1), the nondimensional height hj/(z1 + z2) is successfully approximated by a linear function of Fr. The maximum height of the jet can be predicted by Equation (1).

The effect of the upper fluid (water) thickness z1 on the maximum height of the jet hj is also investigated. Figure 11 shows the relationship between the nondimensional height (hj − z2)/z2 and Re, where C0 = 0.02 and z2 = 50 mm. The height (hj − z2)/z2 is proportional to Re until the jet reaches the upper water surface. The increase in (hj − z2)/z2 at three conditions of z1 is virtually expressed by a single line. The maximum height of the jet is not affected by z1 since the gravitational effect acting on the jet is independent of the depth of the upper fluid.

Figure 12 shows the effect of the lower fluid thickness z2 on hj with the nondimensional height (hj − z2)/z1 plotted against Re, where C0 = 0.02 and z1 = 40 mm. When the jet does not reach the upper water surface, the height (hj − z2)/z1 decreases with increasing z2. This is because z2 corresponds to the distance between the nozzle outlet and the density interface, and therefore an increase in z2 causes a loss in jet momentum due to friction with the ambient fluid prior to reaching the interface.

![]()

Figure 10. Relationship between maximum height of jet and Froude number.

![]()

Figure 11. Effect of thickness z1 on maximum height of jet (C0 = 0.02).

![]()

Figure 12. Effect of thickness z2 on maximum height of jet (C0 = 0.02).

4. Conclusions

In this study, a jet is issued vertically upward from a nozzle into a two-layer density-stratified fluid in a tank. The upper and lower fluids are water and a NaCl-water solution, respectively; and the lower fluid is issued from the nozzle mounted on the tank bottom. The flow is visualized, and the distribution of the concentration of the water paint issued with the jet is measured. The effects of the jet Reynolds number Re, the mass concentration of the NaCl-solution water C0, and the thicknesses of the upper and lower fluids are investigated. The results are summarized as follows:

1) The jet behavior relative to the density interface is classified into three patterns A, B, and C according to Re and C0. Pattern A occurs when Re is extremely low. The jet reaches the interface without penetrating it but spreads almost horizontally outward along the interface. Pattern B appears when Re increases. The jet penetrates the interface but does not reach the upper water surface. The top of the jet falls back to the interface and spreads horizontally without again penetrating the interface. Pattern C appears when Re is further increased. The jet reaches the upper water surface and spreads along the surface.

2) In Pattern A, mixing by the jet occurs only around the top of the jet near the density interface. In Pattern B, mixing appears in the layer region along the density interface. In Pattern C, active mixing occurs in the upper fluid.

3) The flow in the horizontal direction along the density interface is parallel to the flow observed in temperature-stratified fluid, and the intrusion distance is proportional to the 5/6 power of time.

4) The maximum height of the jet can be predicted by the Froude number defined by the density difference between the upper and lower fluids, and is not affected by the upper fluid thickness; however, it decreases with an increase in the lower fluid thickness.

Nomenclatures

C0: mass concentration of NaCl-water solution at t = 0

d: nozzle diameter

Fr: Froude number defined by Equation (1)

g: gravitational acceleration

hj: maximum height of jet

rj: intrusion distance

Re: Reynolds number = dU0/ν

t: time

t*: nondimensional time = tU0/d

U0: mean velocity at nozzle outlet

x, y, z: orthogonal coordinates

z1: vertical thickness of upper fluid

z2: vertical thickness of lower fluid

Γ: concentration

ν: kinematic viscosity of water

ρ1: density of upper fluid

ρ2: density of lower fluid