Triple and Double Photons Absorption Process and Down-Conversion Laser Emitting Investigation of Er-Ion Doped Microsphere ()

1. Introduction

Rare earth doped materials have been widely used for photonic applications including lasers [1], optical fiber amplifiers [2], and laser display [3], optical anti-counterfeiting [4], and anti-Stokes fluorescence laser cooling [5]. Erbium with abundant energy level structures was particularly studied for erbium-doped fiber amplifier (EDFA) [6], optical fiber lasers [1] and up-conversion emissions [7]. In surface-tension induced silica microspheres light can propagate around the inner surface with very low loss due to atomic-scale smooth surface in the manner of total internal reflection, called “whispering-gallery” modes (WGMs). The WGMs attained not only the highest optical quality-factors (Q) (i.e. the temporal confinement of light) [8-10], but also the light is spatially confined, exhibiting small mode volume and high energy density of the optical mode .The small mode volume and long photon storage time can be used for a variety of studies ranging from fundamental physics such as cavity Quantum Electrodynamics [11] to more applied areas nonlinear optical studies [9,10], high-sensitivity transducers for biochemical sensing [12], low threshold light emission and narrow line-width lasers [8], as strong resonant buildup of energy in micro-scale volumes significantly reduces the threshold for light emission to occur. Silica is good host for some rare earth ions including Er (erbium), Yb (ytterbium), Tm (thulium), Ho (holmium) [7,13,14] etc. When silica microspheres are doped with certain number of rare-earth ions, light can be emitted by coupling pump light source with a tapered fiber [15,16]. Microsphere and biconical tapered fiber coupled system is good candidate for study of rare earth doped material light emission. A biconical tapered fiber not only can import pump light into a microsphere, but also can export emitted light into a single mode fiber, which is very convenient for readily measurement.

In this paper, microspheres are fabricated by the electrical-arc melting of the optcal fiber splicer. The diameter of the microsphere ranges from the tens of to the hundreds of micron. A fiber taper made of SMF-28 fiber by HF etching method was used to couple the pump light with emission light or laser out of the microsphere. A semiconductor laser diode at 976 nm and TLS laser (1470 - 1580 nm) are employed to directly excite the Er (erbium)-ion doped silica microsphere.

2. Er-Ion Doped Microsphere and Optical Taper Fiber Fabrication

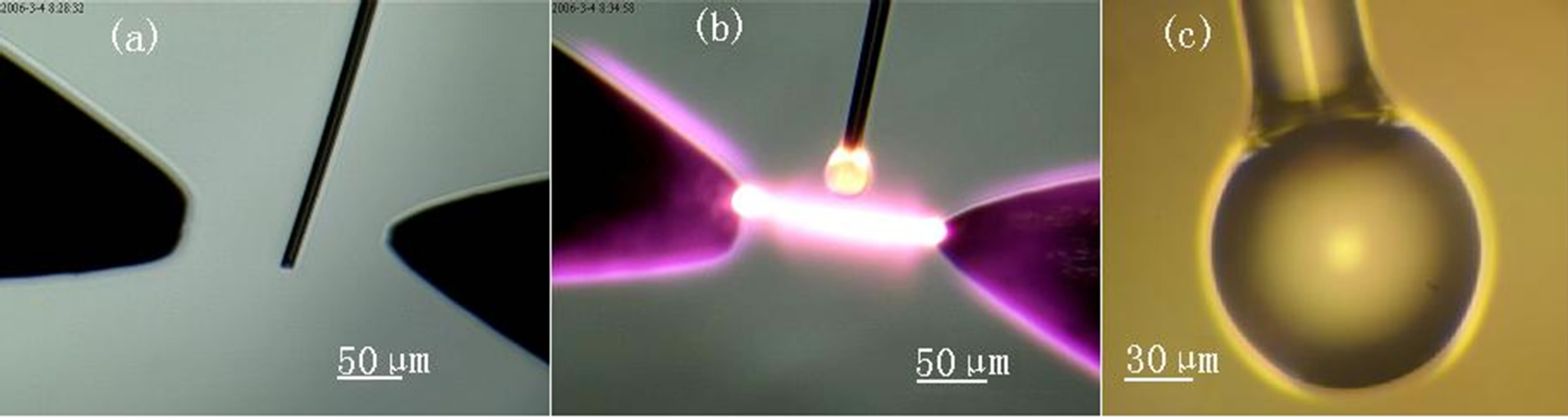

At first, we stripped off the coating of a single mode fiber for 3 cm long. The bare optical fiber was carefully cleaned by acetone and alcohol, then heated with the flame of alcohol lamp and pulled with a steady speed from the ends until it was fractured in the middle, leaving two single tapered fibers. The diameter and length of a taper are related to the pulling speed. In our experiments, the tip diameters of tapers were less than 20 micron. In order to dope Er-ions into silica, a tapered fiber was dipped into a certain erbium nitrate solution, its concentration was about 10−5 - 10−4 mol/ml. Then it was fixed between two thermostability electrodes of splicer (Figure 1B(a)). After the electrodes discharged under the control of circuit, the taper tip was melted in several seconds. After several times of electrical-arc melting, an Er-ion doped silica microsphere was fabricated (Figure 1B(c)), which exhibits a near atomic scale surface finish due to surface-tension-induced.

We present a new HF acid etch setup to fabricate low loss biconical optical tapered fibers with waist diameter between 1.0 μm to 2.5 μm. Instead of the acid baths and an uncontrollable micro-droplet of HF [18], we design a etching groove to obtain different etching rate along the optical fiber as shown in Figure 2.

(A)

(B)

Figure 1. Fabrication of an Er-ion doped silica microsphere. (A) The flow chart of the Er-ion doped microsphere; (B) Electrical-arc melting to fabricate Er-doped microsphere [17].

The etch groove was made from plastic material. There were an oval groove in the mid and two small Vshape grooves in the two sides respectively. As the oval groove was injected with 0.05 ml - 0.06 ml buffered HF (BHF) acid and the two small V-shape grooves were injected full of deioned water, the HF acid solution diffused toward the V-grooves, its concentration decreased gradually along the grooves to etch the fiber to form a graded diameter profile. The V-groove must be small enough to control the diffusion. We terminated an etch by extracting the HF using a pipette and flushing the fiber with deionized water and acetone.

The surface morphology of fabricated tapered fiber was detected by 400× optical microscope and atomic force microscope (AFM) as shown in Figure 3. The roughness of the surface was less than 1 nm. The tapered fiber exhibited excellent surface smoothness.

Figure 2. The setup of using HF acid to fabricate low loss biconical optical tapered. (a) Schematic of a biconical tapered fiber. Lw is the taper length (contracting and expanding regions). Di is the original fiber diameter (125 μm) of a SMF and Dw is the diameter of the waist; (b) The etching groove with an oval in the mid and two small V-shape groove on both sides; (c) The schematic of the etching apparatus: 1. U-shape frame for fixing fiber; 2. Optical fiber; 3. Etching groove; 4. Moveable rod for detaching the etching groove and the final taper fiber; 5. Screw bolt.

Figure 3. (a) Final fabricated taper: an optical micrograph of the waist under 400× optical microscope; (b) The surface morphology of the tapered fiber under AFM.

3. Er-Ion Doped Microsphere Light Emission Measurement and Analysis

3.1. Up-Conversion Fluorescence Emission

Figure 4 is the schematic diagram of measurement setup. An Er-ion doped silica microsphere was firstly pumped by a tunable laser source at 1534 nm. Pump light was imported through single mode fiber to biconical tapered fiber, the tapered fiber it tangent coupled with a microsphere, and the emission light (green fluorescence) and the residual 976 nm light was also exported through the single mode fiber.