Evaluation of Methane Yield on Mesophilic-Dry Anaerobic Digestion of Piggery Manure Mixed with Chaff for Agricultural Area ()

1. Introduction

A methane fermentation process has an advantage in treating organic contaminants for preventing environmental pollution when comparing a conventional aerobic treatment process. Naturally, the methane fermentation process has a combination limit of processes but it is relatively useful in aspects of energy production and resource collection. The methane fermentation process such as an anaerobic digestion process is a skill studied and used for a long time and is recently being magnified in a situation as an international concern focusing on climate change control and renewable energy demand. Especially, a biogas plant, one of the methane fermentation skills, has been used in many countries and known as one of effective strategy techniques for bio-fuel production [1].

Domestic livestock manure emission classified by livestock types has a component ratio as follows; 57.6% piggery manure (740,000 m3/d) and 42.4% cow manure (540,000 m3/d) [2], and dairy cow manure of the cow manure is emitted in the overcrowded area such as farms but few Korean native cattle are raised in small farmers and there are many bad cases in collecting and in treating Korean native cattle manure. The organic content is a raw matter to produce the methane and exists in the piggery manure as low as 2% to 5%. Thus, utilization of the piggery manure as a substrate is low and also it is known well that a stable operation of an anaerobic digestion tank is difficult because a fluctuation range of the organic content is large periodically and the moisture content is high enough [3].

The anaerobic digestion process is divided into a wet process and a dry process according to solid content or moisture content of the substrate used. Until the mid- 1980s, the wet process has been mainly applied in the field using waste matters within 10% solid content as the substrate. With EU as the center rapidly from the 1990s, however, the dry process has been developed to digest organic waste matters containing the solid content over 20% [4]. In treating the high-concentration substrate having low moisture content, the dry process requires low heat capacity to maintain the reactor temperature and discharges low wastewater after treatment [5]. However, it is not valid to put the livestock manure into the dry process directly because the livestock manure emitted from domestic piggery farms contains a great deal of moisture and the solid content of the livestock manure is very low. Meanwhile, the bulking agents such as rice straws, chaff, dead leaves fragments, sawdust, etc. are easy to obtain in the farm area and such agricultural byproducts have been used as the bulking agent for composing manure from old times and also as the carbon supplement for maintaining the proper C/N ratio. Practically, most of domestic livestock farms are located in the farming settlement that is producing a great deal of the bulking agent. In adopting the biogas plant in the domestic farming areas, the dry anaerobic digestion process is in a more advantageous situation than the wet process when considering realistic conditions, In Europe recently, studies on the dry digestion operation for the municipal organic solid waste are actively proceeding to reduce waste amounts for landfill and to produce the bio-energy [6,7]. However, previous studies mainly present that the operation results for high temperature (50˚C - 60˚C) conditions and continuous operation cases are also pretty rare [8].

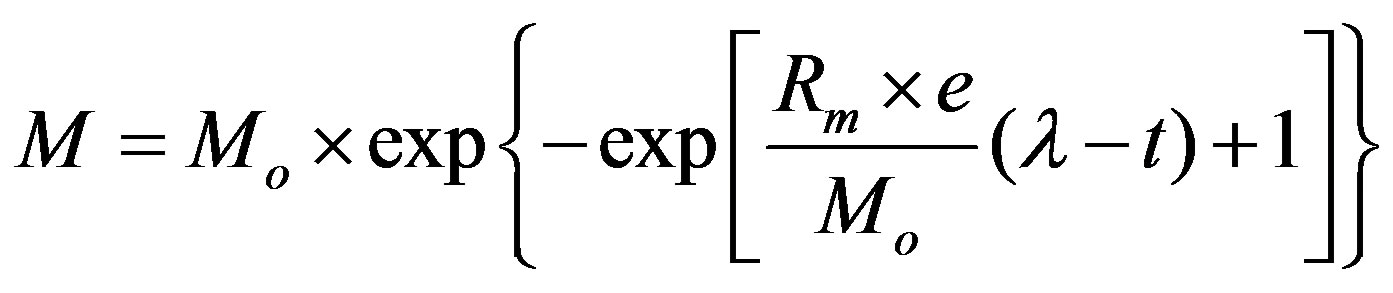

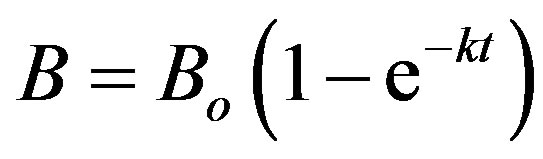

To analyze the ultimate methane production rate (mL/gVSadded) caused by organic matters as the substrate for the anaerobic digestion process, it measures the methane amounts produced during the anaerobic batch incubation period and cumulative methane formula can be used to determine the methane production yield based on the observed data. Representative models such as Modified Gompertz model or Exponential model are used to analyze experiment data obtained through the methane production potential test [9,10]. Using those models described in Equations (1) and (2) as below, comparative studies are variously proceeding to determine the ultimate methane production yield of the substrates related to diverse components [11,12].

Modified Gompertz Model Equation [13]:

(1)

(1)

where, M: cumulative methane production yield (mLCH4/g-VS)

t: incubation time of an anaerobic digestion tank (days)

Mo: ultimate methane production yield (mL-CH4/g-VS)

Rm: maximum methane production rate (mL-CH4/gVS·day)

e: exp (1) = 2.71828182

λ: lag phase, days Exponential Model Equation:

(2)

(2)

where, B: cumulative methane production yield (mLCH4/g-VS)

t: incubation time of an anaerobic digestion tank (days)

Bo: ultimate methane production yield (mL-CH4/g-VS)

k: 1st order reaction rate constant (day−1).

With the purpose of energy resource recovery through the methane production due to the piggery manure in the farming area, this study conducts a series of experiments with the dry anaerobic digestion using the chaff. The chaff is easily obtained in the farming area as one of the byproducts and as the substrate to mix with the manure as well as to control the moisture. The anaerobic digestion has been conducted in the single-phase mesophilic condition, BMP (biochemical methane potential) assay has been applied to estimate the methane production potential due to the several mixture ratios between the piggery manure and the chaff based on the experimental results, and this study has been accomplished to find a way to improve the methane production efficiency.

2. Materials and Methods

2.1. Experimental Equipments and Operation Conditions

In experiments, a batchwise reactor of methane yield is prepared for single-phase anaerobic digestion as shown in Figure 1. For a dry methane production process of livestock manure as a main substrate, typical experimental conditions were adopted to examine gas production yield and responses characteristics. Experiments were set up to control pH if necessary and to incubate for 40 days as controlling to keep typical temperature for mesophilic digestion in a range of 35˚C ± 1˚C [14], and an additional agitator was excluded in the experiments.

Figure 1 describes a schematic diagram of a batchwise single phase digester for methane yield. 0.5 L serum bottles were set up to an incubator at a constant temperature. Operation conditions were monitored for every serum bottle in different mix proportions between piggery manure as a main substrate and chaff as a mixture substrate to control the moisture. Major items such as pH change and the gas production yield from the serum bottle were monitored due to each condition. The operator also

Figure 1. Schematic diagram of batchwise single phase digester for methane yield.

measured generating-capacity and methane content in gas collected in a teflon bag through an exhaust pipe in the middle of a gas-tight rubber stopper of the serum bottle at a constant time interval, every 3 days. Additionally, taking small amounts from all of samples and putting them into each 50 mL-tube, the operator measured its weight per VS (volatile solid) changed with operating under the same conditions.

Table 1 presents operation conditions and a substrate composition in the single phase digester. For two operation parameters such as the substrate concentration and the solid content, the methane production was estimated in different mixing ratios between the piggery manure and the chaff. All samples except a control group (marked as Run 1) were added trace elements in order to minimize unstable effects of microbial growth due to lack of essential elements in the anaerobic digester.