Research on the Seepage Safety Monitoring Indexes of the High Core Rockfill Dam ()

1. Introduction

A number of high core rockfill dams, such as Nuo Zhadu (261.5 m), Shuangjiangkou (314 m), Liang Hekou (293 m) and so on, are being or to be built in China. These extra high core rockfill dams around 300 m have broken through the applicable scope of the current norms. The internal mechanisms of them are complex. What’s worse, they will be faced with disadvantage loading conditions, such as high water head, high stress and eventual earthquake for a long time in the process of service period. Therefore, it is of great difficult to ensure the safety of these water conservancy and hydropower projects [1] [2].

Safety monitoring indicator is a key to quickly determine the dam’s safety state, assess and monitor the safety of a dam. At present, both domestic and foreign researches on dam safety monitoring index mainly concentrate in the concrete dam deformation monitoring indexes [3] [4] [5]. For example, the small probability method, limit condition method, structure analysis and other methods are introduced to formulate the dam safety monitoring indexes in combination with prototype observation data under the unfavorable load combinations. However, these kinds of methods, assuming that the dam is a rigid body or linear elasticity structure, could not be used in the high core rockfill dams because they are nonlinear deformation structures. In terms of the safety evaluation of earth-rockfill dams, hydraulic structure engineers tend to focus more on the seepage and seepage stability of dam, such as seepage, seepage gradient and soil permeability coefficient etc. However, the research on monitoring index is not developed systematic for the moment [6] [7]. Especially for the seepage safety monitoring index research of high core rockfill dams which are rapidly constructed in recent years.

In order to control the safety state of extra high core rockfill dams, ensure the long-term healthy service of the structures and feedback to guide the design theory of high core rockfill dam and the scientific development of damming technology, this article will focus on the change of real-time dam seepage flow, the seepage gradient and local mean soil permeability coefficient, developing three seepage safety monitoring indexes for extra high core rockfill dam.

2. Seepage Quantity Safety Monitoring Index

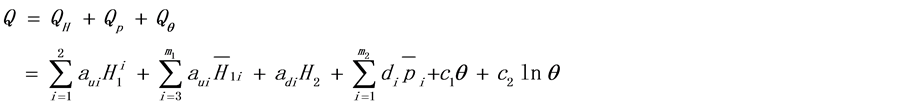

Seepage failure is one of the main crash modes of high core rockfill dam, and the monitored seepage quantity is a comprehensive effect of the seepage state. Therefore, develop a seepage quantity monitoring index will provide a technical guidance for the safety of high core rockfill dam. In the process of developing a seepage quantity monitoring index, a number of factors should be taken into consider, including reservoir level, rainfall, and the role of material time-varying effect for seepage flow, as well as statistical characteristics of the monitoring data. In the following part, the seepage statistical model are used for fitting the relation between the monitoring effect values and the corresponding loads, environmental factors, predicting the development law of seepage quantity. The confidence interval is used to consider the false alarm caused by the monitoring errors, and the seepage safety monitoring work is carried out then. Figure 1 describes the overall process of fitting, forecasting and developing the seepage

![]()

Figure 1. Fitting curve and the confidence interval.

quantity monitoring index by the above model and confident interval method.

The monitored seepage quantity of the high core rockfill dam is mainly affected by the reservoir level, the downstream water level, the rainfall infiltration and the time-varying factors of the impervious body. Therefore, the statistical model for seepage flow of high core rockfill dam can be expressed by water level component , rainfall component

, rainfall component  and aging component

and aging component :

:

(1)

(1)

where:  ――The upstream depth of water on the observational day;

――The upstream depth of water on the observational day;  ―― downstream depth of water on the observational day;

―― downstream depth of water on the observational day;  ――average upstream depth of water on the ith day before the observation;

――average upstream depth of water on the ith day before the observation;  ――days of Lag;

――days of Lag;  ――Prophase rainfall quantity;

――Prophase rainfall quantity;  ――the days after initial impoundment divided by 100.

――the days after initial impoundment divided by 100.

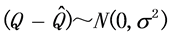

The samples of monitoring effect values can be divided into fitting sets and forecasting sets. Then a mathematical model between fitting set data of monitored effect values and loads can be established. After establishing the statistical model of monitored seepage quantity, the predicted value of the effect  can be obtained using the above model and the environment values during the period of forecasting. When comparing the predicted value with the monitored effect value of the corresponding time, the standard deviation

can be obtained using the above model and the environment values during the period of forecasting. When comparing the predicted value with the monitored effect value of the corresponding time, the standard deviation  is used to determine the confident internal

is used to determine the confident internal  considering the effects of modeling error and forecasting error. It is assumed that the error between monitored values

considering the effects of modeling error and forecasting error. It is assumed that the error between monitored values and predicted values

and predicted values  obeys the normal distribution with mean to 0 and the variance is

obeys the normal distribution with mean to 0 and the variance is  .That is

.That is . Then, The probability that

. Then, The probability that ![]() is included in confident internal

is included in confident internal ![]() is

is ![]() .

.

![]() (2)

(2)

According to the statistical theory, the above error event is a small probability event when the significance level ![]() value is 1% or 5%. Thus:

value is 1% or 5%. Thus:

![]() (3)

(3)

where: ![]() ――Standard deviation of mathematical model;

――Standard deviation of mathematical model;![]() ――function of

――function of ![]() (satisfy condition:

(satisfy condition: ![]() =1%,

=1%, ![]() =2.58;

=2.58; ![]() =5%,

=5%, ![]() =1.96);

=1.96);

By the above method, the seepage safety monitoring index of high core rockfill dam can be obtained ![]() :

:

1) When ![]() , normal value;

, normal value;

2) When ![]() , a tracking monitoring should be carried out. The seepage is is normal when it does not increase persistently; otherwise, the seepage is abnormal, and an alarm of monitored seepage quantity and its cause analysis should be carries out immediately;

, a tracking monitoring should be carried out. The seepage is is normal when it does not increase persistently; otherwise, the seepage is abnormal, and an alarm of monitored seepage quantity and its cause analysis should be carries out immediately;

3) When ![]() , the monitored values are significantly abnormal. an alarm of monitored seepage quantity and a comprehensive check on the serving states of dam should be carries out immediately. In this case, the operation of reservoir should be controlled timely according to the safety of the dam.

, the monitored values are significantly abnormal. an alarm of monitored seepage quantity and a comprehensive check on the serving states of dam should be carries out immediately. In this case, the operation of reservoir should be controlled timely according to the safety of the dam.

3. Permeability Gradient Safety Monitoring Index

High core rockfill dam is mainly composed of rockfill body and impervious core wall, which is shown in Figure 2. After the water storage and operation, the core wall seepage pressure is mainly influenced by reservoir level instead of time-va- rying effect with the consolidation of the core soil. The internal core wall permeability gradient will ascend along with the water level upgrade. A high level of permeability gradient would lead to local failures of the core wall and seepage abnormal accident, if the permeability gradient is more than the allowable value. In this case, piping, soil flow and different types of soil surface contact failures may occur in the dam foundation. Therefore, it is of great significance for prevention and control the seepage failure in the core wall and foundation to develop the permeability gradient safety monitored indexes.

Through the seepage pressure monitoring, the level and distribution of the seepage pressure in dam foundation can be timely monitored, the possibility of local penetration failure can be determined and the performance of overall anti- seepage can be evaluated. The conventional seepage pressure monitoring of the high core rockfill dam includes seepage pressure monitoring of dam body and foundation. The former mainly laids osmometers in 3 - 5 main observation elevation section, which is generally located in the center line of core wall, its upstream and downstream sides and the downstream fine filter, focusing on the pressure distribution and the location of saturation line of the section. Seepage

![]()

Figure 2. Structure of high core rockfill dam.

pressure monitoring of dam foundation laids osmometer in the contact area between core wall and concrete cushion and excavation surface, focusing on the seepage pressure in the contact surface and foundation after water storage. Figure 3 is a typical layout of the core wall pressure gauges.

The monitoring indexes could be designed corresponds to the alarm values which is developed under the most unfavorable loads combination. Then these indexes can be used to evaluate and predict the loads with stranding ability of a dam. Based on this philosophy, the idea that controling of monitoring permeability gradient without exceeding its allowable value, can be used as a method to monitor the seepage stability of core wall and foundation.

According to the monitoring values of the measured points which is in the same height in the main observation section, the monitoring permeability gradient![]() between the adjacent points can be calculated. Expressions are as follows:

between the adjacent points can be calculated. Expressions are as follows:

![]() (4)

(4)

where: ![]() ――The distance between the ith and the (i + 1)th osmometer;

――The distance between the ith and the (i + 1)th osmometer;

![]() ――The monitoring pressure of the ith osmometer.

――The monitoring pressure of the ith osmometer.

In accordance with the dam desination principles, the local permeability gradient of the core wall should be less than allowance value![]() , in order to satisfy the requirements of permeability stability. The selection of allowance permeability gradient should consider the maximum permeability gradient in the most unfavourable loading conditions through finite element simulation, as well as the design values of allowance permeability gradient in filling material. Therefore, the allowance permeability gradient

, in order to satisfy the requirements of permeability stability. The selection of allowance permeability gradient should consider the maximum permeability gradient in the most unfavourable loading conditions through finite element simulation, as well as the design values of allowance permeability gradient in filling material. Therefore, the allowance permeability gradient ![]() is taking by the smaller one of

is taking by the smaller one of

![]()

Figure 3. Layout of pressure gauges in core wall.

above values.

It should be noted that, the permeability gradient between adjacent osmometer calculated from the above process belongs to the average one. It is not conservative to use this value carrying out the safety monitoring tasks. Considering the effect of this factor, a reasonable selection of safety coefficient![]() , which is given in accordance with the class of dam structure, is taken here to adjust safety redundancy of allowance permeability gradient. In the practical projects, value

, which is given in accordance with the class of dam structure, is taken here to adjust safety redundancy of allowance permeability gradient. In the practical projects, value ![]() is usually taken in the range 1.5 - 3.0. The local permeability failure of core wall are developing gradually, therefore, the failure process can be reflected also through the changing rate of permeability gradient

is usually taken in the range 1.5 - 3.0. The local permeability failure of core wall are developing gradually, therefore, the failure process can be reflected also through the changing rate of permeability gradient ![]() between adjacent test point.

between adjacent test point.

Therefore, the safety monitoring index is expressed as follows:

![]() (5)

(5)

where: ![]() ――Maximum permeability gradient calculated by the finite element model under the most unfavorable loads combination;

――Maximum permeability gradient calculated by the finite element model under the most unfavorable loads combination; ![]() ――The designed value of allowance permeability gradient of building material;

――The designed value of allowance permeability gradient of building material; ![]() ――The safety factor in accordance with the class of dam structure.

――The safety factor in accordance with the class of dam structure.

(1) When ![]() , the dam is in a normal state;

, the dam is in a normal state;

(2) When![]() , a tracking monitoring should be carried out. The seepage is is normal when it does not increase persistently; otherwise, the seepage is abnormal, and an alarm of monitored permeability gradientues and its cause analysis should be carries out immediately;

, a tracking monitoring should be carried out. The seepage is is normal when it does not increase persistently; otherwise, the seepage is abnormal, and an alarm of monitored permeability gradientues and its cause analysis should be carries out immediately;

(3) When![]() , the monitored values are significantly abnormal. An alarm of monitored permeability gradientues and a comprehensive check on the serving states of dam should be carries out immediately. In this case, the operation of reservoir should be controled timely according to the safety of the dam.

, the monitored values are significantly abnormal. An alarm of monitored permeability gradientues and a comprehensive check on the serving states of dam should be carries out immediately. In this case, the operation of reservoir should be controled timely according to the safety of the dam.

4. Soil Permeability Coefficient Safety Monitoring Index

In the long-term service of the core rockfill dam, the dam has to withstand the static & dynamic cycle load, all kinds of sudden disaster, and corrosion from harsh environment. These factors may lead to the changes in the physical and mechanical properties of the dam material and structural properties of the dam, which results in a tendency to bring about a declining safety performance. The average permeability coefficient of the core wall is an important parameter of the seepage field in the high core rockfill dam, and it will presents time variation behavior with the service of the project. Therefore, it is of great value to judge the health status of dams from the perspective of the permeability coefficient of the core wall filling material. The monitoring index of the average permeability coefficient of the core wall can guide the safety management of the high core rockfill dam. Here, the permeability coefficient refers to the average value of the regional permeability coefficient selected in the structural numerical analysis.

The permeability coefficient is defined as the unit flow rate under unit hydraulic gradient, which comprehensively reflects the permeability of soil. The permeability coefficient is related to the shape, size, unevenness coefficient and water viscosity of soil particles. In addition to the indoor test and the field pumping and water injection test, we can also use the finite element calculation combined with the prototype monitoring data to invert the permeability coefficient. First of all, we make use of the upstream water level ![]() range from dead water level to checkflood level and the total seepage quantity

range from dead water level to checkflood level and the total seepage quantity ![]() within

within ![]() to inverse the permeability coefficient. On the basis of a large number of inversion results, the mapping relationship among the average permeability coefficient K, upstream water level H and seepage quantity Q is established. Then, according to the idea of positive analysis, K is calculated from H and Q.

to inverse the permeability coefficient. On the basis of a large number of inversion results, the mapping relationship among the average permeability coefficient K, upstream water level H and seepage quantity Q is established. Then, according to the idea of positive analysis, K is calculated from H and Q.

It is assumed that the effect of seepage-prevention wall in the core rockfill dam is good enough and monitored most of the seepage quantity through the core wall. The core wall is divided into![]() units, so that we can calculate the seepage pressure value of core wall inside each unite nodes in the corresponding seepage quantity and water level boundary conditions by the finite element method. Then calculate the hydraulic gradient at the centroid of the elements. The average permeability coefficient K of the core wall can be expressed as:

units, so that we can calculate the seepage pressure value of core wall inside each unite nodes in the corresponding seepage quantity and water level boundary conditions by the finite element method. Then calculate the hydraulic gradient at the centroid of the elements. The average permeability coefficient K of the core wall can be expressed as:

![]() (6)

(6)

where: ![]() ――Area of unit i;

――Area of unit i; ![]() ――The hydraulic gradient at the centroid of the elements.

――The hydraulic gradient at the centroid of the elements.

After obtaining the inversion analysis results of a large number of permeability coefficients, the ![]() curves for different upstream water levels H can be drawn. At present, the inverse process can be simplified by using neural network in the back analysis of model parameters, which not only can get the permeability coefficient inversion results directly, avoiding the traditional interpolation cumbersome, but also can make up the defect of the finite element computation time.

curves for different upstream water levels H can be drawn. At present, the inverse process can be simplified by using neural network in the back analysis of model parameters, which not only can get the permeability coefficient inversion results directly, avoiding the traditional interpolation cumbersome, but also can make up the defect of the finite element computation time.

Firstly, we select the appropriate neural network such as the least squares support vector machine, the head H and total flow rate Q as the input vector, the permeability coefficient K as the output vector to establish the nonlinear relationship among K, H and Q. Then H and Q are input into the trained neural network model, the inversion value of K can be obtained.

Based on the above method, we inverse permeability coefficient for each group of upstream water level and total seepage. The impermeability of the core wall material is analyzed by comparing K and the allowable value [K]. The safety monitoring index of soil permeability coefficient can be expressed as:

![]() (7)

(7)

where:![]() ――Safety factor.

――Safety factor.

1) When![]() , the dam is in a normal state;

, the dam is in a normal state;

2) When![]() , the variation law and development trend of permeability coefficient are analyzed. If there is no continuous increasing and trending changes, the dam behavior is normal, otherwise it is abnormal.

, the variation law and development trend of permeability coefficient are analyzed. If there is no continuous increasing and trending changes, the dam behavior is normal, otherwise it is abnormal.

5. Engineering Case

The Nuozhadu Hydropower Station is located in the junction area of Lancang County and Cuiyun district in Simao City, Yunnan province, the downstream of Lancang River. The project is a large (1) type engineering, mainly for power generation. The main water-containing structure is a core wall rockfill dam with a maximum height of 261.5 meters, third at the same type of dams in the world. The normal water level is 812.0 m and dead water level is 765.0 m.

5.1. Seepage Safety Monitoring Index

The weir point DB-WE-02 near the 7# grouting hole in the right bank of Nuozhadu dam is selected in this case. The statistical model of seepage quantity is established as follows, based on the monitoring data and Equation (1) in this paper:

![]() (8)

(8)

the complex correlation coefficient of the statistical model is 0.88, which is in high accuracy. Therefore, the above monitoring model will reflect the changing behavior of seepage quantity of DB-WE-02, and the seepage monitoring indexes can be developed using this model. The developed seepage quantity monitoring indexes is shown in Table 1.

5.2. Permeability Gradient Safety Monitoring Index

The internal osmotic pressure gauges, DB_C_P_50~52, DB_A_P_24 ~ 26, DB_ D_P_24 ~ 26, on the 780m elevation of three sections (A, C and D subjective monitoring section) in core wall of Nuozhadu dam is selected here. Then, the gradient between adjacent monitoring points according to is calculated according to Formula (4). Figure 3 demonstrates the changes of monitoring process lines of monitored permeability gradient on the 780 m elevation of the core wall.

According to the planar seepage analysis and 3D seepage analysis results from feasibility study report of Nuozhadu dan, the maximum permeability gradient

![]()

Table 1. Monitoring indexes of seepage flow rate at DB-WE-02.

in the downstream location of the core wall is 7 - 8, and this value satisfies with the requirements of seepage control and seepage stability. Therefore, the maximum seepage gradient is chosen to be the allowance seepage gradient when developing the seepage gradient safety monitoring index, namely ![]() = 7.5. At the same time, according to the design law of earth rockfill dam, a safety factor K = 2 is selected in accordance with the dam project scale.

= 7.5. At the same time, according to the design law of earth rockfill dam, a safety factor K = 2 is selected in accordance with the dam project scale.

The seepage gradient monitoring indexes are developed in Table 2, and safe area of seepage gradient is marked in the red line area of Figure 4.

5.3. Permeability Coefficient Safety Monitoring Index

A finite element model of the highest section C-C of Nuozhadu dam is established by Geo studio firstly, which is shown in Figure 5. The seepage parameters of different dam sections are shown in Table 3. In order to reduce the calculation error, an inversion analysis is carried out using the monitored data in November 2015, in which time the upstream and downstream water lever and rainfall factor is relevantly stable. Specifically, the typical upstream water level is 791.12 m, the downstream water level is 602.06 m, the monitored seepage flow is 11.57 L/s. The upper and the downstream boundary conditions are applied, and 11 sets of permeability coefficients are calculated by finite element method in the range of 2 × 10−9 ~ 2 × 10−7m/s.

It is necessary to convert the unit width quantity of the cross-section C-C into the total seepage quantity of the dam. Here, the dam body is divided into several

![]()

Figure 4. Curves of the measured seepage gradients between adjacent monitoring points in 780m height of core wall.

![]()

Table 2. Permeability gradient monitoring index.

![]()

Figure 5. Finite element model of Nuozhadu core rockfill dam.

![]()

Table 3. Seepage parameters of different dam sections.

sections along the axis due to the geometry of each dam section. It is assumed that the underwater area is proportional to the unit width quantity. The total seepage quantity of the dam can be expressed as:

![]() (9)

(9)

where:![]() ――unit wide quantity of C-C section;

――unit wide quantity of C-C section;![]() ――Depth of front C-C section;

――Depth of front C-C section;![]() ――Total underwater area front dam.

――Total underwater area front dam.

The finite element calculation results of total seepage quantity and the total seepage quantity of dam after conversion are obtained accordingly. The results indicate that when the total seepage quantity is 11.57L/s, the inversion value of permeability coefficient is 1.71 × 10−8 m/s. The average values of DB-C-P-20, DB-C-P-22, DB-C-P-30 and DB-C-P-31 in November 2015 were used to test the inversion reliability of permeability coefficient. Table 4 lists the calculated values and monitored values of the osmometers. In this table, the relative error is 0.24%, 0.69%, 3.04%, 3.00%. It is indicated that the inversion values is taken in good accuracy, and it is of great value to obtain the permeability coefficient.

According to the “design specifications of roller compacted earth dam”, the permeability coefficient of the core wall should satisfy the norm that it should be lower than 1.0 × 10−7 m/s. A safety factor K = 2 is taken as well. Then, the permeability coefficient monitoring indexes is developed in Table 5.

6. Summary

In this paper, three safety monitoring indexes: seepage quantity monitoring in-

![]()

Table 4. Comparison of calculated values and measured values of dam barometer.

![]()

Table 5. Permeability coefficient safety monitoring index.

dex, permeability gradient monitoring index and local average permeability coefficient monitoring index are developed from the perspective of the seepage characteristics and the failure mechanisms of the high core rockfill dam. Among them, the seepage quantity safety monitoring index, based on the whole seepage quantity monitoring data, is simple and easy to developed, on basis of obtaining high reliability, long series and good integrity monitoring data. The permeability gradient safety monitoring index, describing the spatial seepage pressure distribution of main monitoring sections, owns the ability of monitoring the local abnormality of core wall and dam foundation. The local average permeability coefficient safety monitoring index, based on structural simulation and inversion analysis of monitoring data, takes into account of the overall and local seepage state in high core rockfill dam.

Acknowledgements

This work was supported by research funds from National Natural Science Foundation of China (Grant Nos. 51379068, 51279052, 51179066), Jiangsu Natural Science Foundation (Grant Nos. BK20140039), Jiangsu Basic Research Program (Grant Nos. BK20160872), Priority Academic Program Development of Jiangsu Higher Education Institutions (Grant No. YS11001), and Key Laboratory of Earth-Rock Dam Failure Mechanism and Safety Control Techniques, Ministry of Water Resources (Grant Nos. YK914002).