Effect of Lithium Chloride on the Fibre Length Distribution, Processing Temperature and the Rheological Properties of High-Yield-Pulp-Fibre-Reinforced Modified Bio-Based Polyamide 11 Composite ()

1. Introduction

Short-fibre reinforced polymer composites are extensively used in manufacturing industries due to their light weight and improved mechanical properties [1] [2] . Hence, HYP has been used not only for its low lignin content, but also for its potential thermal stability and its strong adhesion when it is bonded with high- temperature engineering thermoplastic polymers [3] [4] [5] [6] .

Various experimental studies have investigated the effect of flexibility on fluid viscosity. They concurred that the more flexible the fibres are, the more pronounced their effect on the rheological characteristics is [7] [8] [9] . A recent study on the effect of fibre-length distribution on the rheological behavior of castor-oil composite showed that at high fibre length, the shear viscosity becomes more dependent on shear rate [10] . This behavior is due to elastic deformation of the fibres [10] .

Recently, various authors have investigated the effect of fibre content on polymer melt rheology [11] [12] [13] . Their study showed an important increase in shear viscosity with increased fibre loading at low shear rates, but only a small increase in viscosity at high shear rates [12] [13] . Another similar study on polypropylene-based long fibre observed an increase in shear viscosity with increased fibre content and fibre length [13] . However, this viscosity rise was very small, which the authors attributed to high shear rates and fibre breakage during the processing [13] [14] . Non-Newtonian fluid characteristics such as shear thinning were also observed in all the studies mentioned above.

There is only a very limited literature devoted to experimental studies of the rheology of pulp-fibre?reinforced polymer composites due to the complex nature of these materials and the difficulties encountered during their processing and their rheological characterization [13] [14] [15] [16] [17] .

The processing technique and conditions have a significant influence on the rheological and overall properties of pulp-fibre-reinforced polymer composites because they dictate the degree of dispersion and distribution of the fibre in the polymer matrix and the low processing temperature required in order to avoid thermal degradation [18] [19] [20] [21] . Compared to other natural fibres, HYP is more thermally stable in the presence of high-melting-temperature engineering thermoplastics (under 180˚C) such as PA11, PA6, and PA66.

The principal objectives of the study described in this chapter were to determine the effect of the addition of the inorganic salt lithium chloride (LiCl) to the bio-based polyamide 11, and the characteristic of the modified bio-based polyamide 11 in the presence of high yield pulp (HYP) fibre. The HYP fibre content, the length distribution, and the density of the composites were measured and analyzed for both processing techniques in order to investigate the effect of LiCl on the composite components. Finally, the rheological results using the Brabender mixer technique and the conical twin extruder respectively were determined and compared.

2. Material and Methods

2.1. Materials

The matrix biopolymer bio-based polyamide 11, density 1.03, MFI 11, was supplied by Arkema (France). Aspen high yield pulp (HYP) fibres were supplied by Tembec (

Montreal

,

QC

). The HYP is the type used in wood-free printing, in writing-paper grades and in multiple-coated folding-board grades; fibre length is 0.230 to 0.85 mm.

2.2. Methods

2.2.1. Composites Preparation

The experiment was processed using a conical twin screw extruder and a Brabender mixer technique. In both mixing processes, the high yield pulp “HYP” fibre was dried at 80˚C for 6 hours and then added to the corresponding bio-based polyamide PA11 and well mixed before the combination was introduced to the extruder. The average temperature of the barrel was 200˚C. Figure 1 represents the different zones of the conical twin-screw extruder. In addition, in the Brabender mixer technique process, different lithium chloride content “LiCl” was added to the bio-based polyamide 11 at corresponding process temperature prior to adding the pulp fibre.

2.2.2. Effect of Processing Conditions

Many processing parameters affect the properties of final products. For extrusion, temperature profiles affect the fibre degradation. In addition, screw speed

![]()

Figure 1. Schematic figure of twin-screw extruder.

![]()

Table 1. Extrusion temperature profile for 10%, 20% and 30% HYP/PA11, 120 rpm (10% and 20%), 130 rpm (30%) and 10 rpm feed rate.

and feeding rate change fibre length, distribution, and orientation. The mechanical properties reflect all these changes, and the processing parameters are optimized to obtain the best properties. Table 1 represents the processing parameters for HYP/PA11 used in this study.

However, the Brabender mixer technique was used as the principal compounding process in this study. Inorganic salt lithium chloride (LiCl) was added to bio-based polyamide 11 in order to decrease it melting temperature, and consequently avoid fibre degradation and burning. Different lithium chloride content was used to reduce the melting temperature of polyamide 11 using the Brabender mixer technique.

2.2.3. Fibre Content and Length Distribution Analysis after Compounding

The composite samples were cut into small pieces and immersed in formic acid for three days. The bio-based PA11 was dissolved by the formic acid and HYP was left. The HYP was filtered and washed with formic acid, then dried in a vacuum oven for four hours. By measuring the weight of composite and pulp fibre, we could calculate the actual fibre content.

HYP fibre length was measured with the Fiber Quality Analyzer (FQA). The HYP was diluted with D.I. water. The diluted HYP fibre entered a thin-planar channel. This channel helped to gently orient the fibre 2-dimensionally, so that the fibre could be fully viewed by the camera. The picture taken by the camera was then analyzed by the software to give the HYP fibre length distribution.

2.2.4. Actual Density Measurement

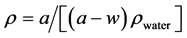

The density of polyamide 11 reinforced HYP fibre composites was determined by using the ASTM D792 technique. The samples were first weighed both in water and air, and then the density was calculated by:

(4.1)

(4.1)

where  is the sample density in g/cm3,

is the sample density in g/cm3,  is the sample weight in air in g, w is the sample weight in water in g, and

is the sample weight in air in g, w is the sample weight in water in g, and  is the density of the water in g/cm3.

is the density of the water in g/cm3.

2.2.5. Differential Scanning Calorimetry (DSC)

The melting temperature and crystallization behavior of the yield pulp fibre reinforced bio-based polyamide 11 composites were investigated using a TA instrument Q1000 differential scanning calorimeter (DSC) attached to a cooling system under a nitrogen atmosphere. The DSC instrument was run from 45˚C to250˚C with a heating rate of 10˚C /min. The sample weight was about 5 mg. The specimens were sealed in aluminum pans by pressing and the prepared samples were placed in the furnace of DSC with an empty reference pan. The heat flow rate as function of temperature was recorded automatically. Melting temperature was identified on the peak point of the DSC curves. The melting of polymer within a composite system would assist to select a suitable temperature profile for the compounding process technique when the fibres and matrix were compounded to produce green composite.

2.2.6. Rheological Properties Measurement

The rheological measurements of the composites’ melt-flow properties of were carried out in a twin-bore Rosand Capillary Rheometer model RH2000. (The standard RH2000 range supports temperatures from −40˚C to 500˚C. The standard maximum force applied is 12 kN.) The composite samples for testing were cut into very small pieces, then placed inside the barrel and forced down into the capillary with the plunger attached to the moving cross-head. Representative steady-shear viscosity versus high shear rate is presented in the figures below for HYP/PA11, which was processed at the average extrusion temperature of 200˚C. The viscosity of the sample was obtained from steady-shear measurements for different temperature profiles, with the rate ranging from 50 to 5000 S−1. The rheological viscosity data presented in this chapter thus represents an average value of three measurements.

3 Results and Discussion

3.1. Effect of the Lowering the Processing Temperature on the Pulp Fibre Distribution and the Bio-Based Polyamide Density after Processing

To avoid the degradation of the HYP fibre during the processing of the composite, decreasing the melting temperature was attempted. The reduction of the melting point of high-temperature-engineering polyamide was realizing by the utilization of inorganic salt during the melt compounding processing in order to lower the melting temperature of polyamide 11 (PA11). Lithium chloride (LiCl) was added to the polyamide 11 during the extrusion process using the Brabender mixer technique. Next, the PA 11 and salt mixture was used as a matrix and HYP fibre was incorporated into the matrix using a Brabendermixer for the compounding.

The melting temperatures of the PA 11/LiCl mixture are shown in Table 2. Table 3 shows the heat deflection temperatures of the PA11 polymer-reinforced HYP fibre composites. 3% LiCl in PA11 was chosen in order to keep the concentration of LiCl low. From 3% to 5% LiCl in the PA11, the change in melting temperature is insignificant. The stability of the melting point at high LiCl concentration is due to the lowering of the crystallization temperature and the saturation of the degree of crystallinity of the molecular chains.

The heat deflection temperature was investigated for only 3% LiCl content. The addition of LiCl to PA11 decreases the crystallization temperature and degree of crystallinity. Consequently, the heat deflection temperature of PA11 de-

![]()

Table 2. Melting temperatures of neat PA11 and modified PA11 with varying LiCl content.

![]()

Table 3. Heat deflection temperatures of polyamide 11 and HYP-fibre-reinforced bio- based PA11 composites.

creased from 135˚C to 52˚C of neat PA 11. However, with the addition of 10% HYP fibre, the heat deflection temperature (HDT) increased to as high as 118˚C. For 30% HYP added to the modified PA11, the heat deflection temperature rises up to 138˚C. The higher is the content of the pulp fibre, the higher is the heat deflection temperature of the composite. The increase in the heat deflection temperature (HDT) of the resultant composite is proportional to the concentration of high yield pulp fibre to the modified PA11 and LiCl.

3.2. Densities and Actual Fibre Contents

The fibre contents of composites were controlled by the feeding rate of matrix and fibre. However, the feeding rate cannot be calibrated precisely, especially the feeding rate of HYP fibre. Table 4 shows the densities and actual fibre contents of composites processed by the extrusion compounding method and the Brabender mixer technique.

Comparing the densities of bio-based polyamide 11 reinforced HYP composites made by the two procedures, we can see that the composites made by the Brabender mixer technique have higher density than composites made by the extrusion process at the same fibre content. The 30% HYP/PA11 made via the Brabender mixer has a higher density because its actual fibre content is 5% higher than the composite made by the extrusion process. The different densities show that Brabender mixer technique gives samples with fewer voids than the extrusion process.

The modified bio-basedPA11 reinforced HYP fibre composites have higher densities than the regular bio-based PA11-reinforced HYP fibre composites at

![]()

Table 4. Densities and actual high-yield fibre contents.

the same fibre content even though the modifiedPA11 has a slightly higher density than regular PA11. The reduction of the melting point, thus viscosity, could lead to a better fibre-matrix wetting to eliminate free volume, holes/voids in the biocomposite with LiCl.

To minimize fibrethermal degradation, the processing temperature was set just below the commercial melting temperature of polyamide. Table 4 shows that the densities and actual fibre contents were proportional to the fibre content for both processing methods. However, with the addition of LiCl to the Brabender mixer, the differences became more pronounced.

3.3. Effect of Fibre Content on the Length and Shape Distribution on HYP-Reinforced Bio-Based Modified PA11 Composite

During the extrusion process, the shear stress applied by the screw breaks the fibres. The resulting fibre lengths affect the ultimate mechanical properties. In spite of the influence of fibre damage and breakage during processing, the initial fibre length in the feedstock determined the final fibre lengths. It was therefore important to analyze the initial fibre-length distribution, which is one of the most significant parameters for natural fibre reinforced polymer composites. After the polymer and fibre for the composite are decided on, fibre length is the adjustable feature used to manage the ultimate properties of bio-composite materials. Table 5 shows the results of HYP fibre length distribution determined using a Fibre Quality Analyzer (FQA).

The arithmetical length and the length-weighted values of HYP fibre length were found to be 0.20 mm, 0.27 mm, and 0.49 respectively for the pulp fibres from 30% HYP/PA11. The arithmetic and length-weight measured values for 20% of pulp fibre were 0.24 mm and 0.36 mm, and for 10% pulp fibre they were 0.29 mm and 0.41 mm. Most of the fibre lengths lie within the range of 0.20 mm to 0.57 mm, since HYP fibre was used in this study. To obtain these average fibre lengths, 1500 single fibres were examined. The measured initial fibre length is greater than the actual length of the fibres in the composites. The HYP fibre length decreases inversely with the increase of pulp fibre content in the compos-

![]()

Table 5. Fibre length distribution of pulp fibre (extrusion compounding process).

![]()

Table 6. Fibre length distribution of pulp fibre (Brabender mixer approach).

ite. This decrease of fibre length with the pulp fibre content in the polymer melt concentration is due to fibre entanglement and agglomeration within the polymer.

Table 6 shows that the HYP fibre length from the green composite produced using the Brabender mixer technique did not decrease very much compared with the HYP fibre length of the composite made using the conical twin extruder method. For modified bio-based PA11-reinforced pulp fibre bio-composites processed using the Brabender mixer technique, the mean fibre length did not decrease a great deal. In the normal bio-based PA11 reinforced HYP fibre composites, the HYP fibre length is shorter than that of the bio-based modified polyamide reinforced pulp fibre after extrusion, probably because the higher temperature caused more thermal degradation of fibres, making them easier to break. In addition, the use of LiCl to decrease the melting temperature of the bio-based PA11 may also have protected the pulp fibre from degradation and entanglement during the slow and controlled process using the Brabender mixer technique, and consequently kept the pulp fibre length constant after the compounding process.

3.4. Rheological Characteristics of HYP-Reinforced Bio-Based Polyamide

As already noted, rheological characteristics of the polymer, fibre, and interphasial phases influence the final characteristics of the resultant microstructure of the composite materials; these characteristics in turn affect the mechanical properties of a multiphase polymer-composite system. As obtained from experiment, the shear viscosity as a function of the steady-shear rate of HYP/PA11 at 200˚C is shown in Figure 2 (As noted, these results are the average of three

![]()

Figure 2. Shear viscosity vs. shear rate of HYP/PA11 at 200˚C.

different experimental tests.)

As noted, the composite material used in the experimental study had an average fibre length of 0.73 mm, and the experiment was conducted at 200˚C. The experimental results showed that the viscosity of HYP/PA11 composite decreases with increasing shear rate. This decrease in the shear viscosity with the increase of the shear rate corresponds to the pseudoplastic fluid characteristic of the composites. This pseudoplastic behavior (also referred to as shear-thinning behavior) as plotted in Figure 2 is mainly influenced by the orientation of the polymer molecules, the agglomeration of the flexible pulp fibre, and the entanglements within the polymer chains in the capillary rheometer. The chain agglomerations are produced simultaneously, as one chain is collapsed into another chain. The entanglements that lead to agglomerations of the chains, as well as the entanglements within the chains, are caused by the Brownian motions and low relaxation of HYP fibre. The high shear-thinning behavior obtained for HYP/PA11 can be also associated to the thermal degradation of HYP during the rheological testing and the compounding process. The molten polymers tend to arrange themselves with their major axes in the direction of shear, whereby points of entanglement are reduced. As a result, the viscosity decreases. In other words, in this instance of non-Newtonian flow behavior in polymer melts, the decrease in viscosity when the shear rate is increased by applying load is associated with high shear-thinning behavior and with viscoelastic characteristics of biocomposite materials. However, at very high shear rates (from 3000 to 5000 S−1) the molten HYP/PA11 showed a less restrained decrease in viscosity. This non-Newtonian behavior is associated with the alignment and orientation of the fibre in the polymer chains and the effect of the fibre aspect ratio. Both at low and high shear rates the formation of agglomerates is evident; therefore, the pulp molecules are completely oriented due to the good dispersion in the bio-based PA11 matrix. This means that the breakage of the fibre length allows the maintenance of an accurate fibre-aspect ratio when the diameter of flexible HYP is kept unchangeable during the process. The shorter length of the fibres also supports their alignment in the direction of the flow, thus reducing the fibre-fibre collisions and leading to a greater decrease in apparent viscosity.

![]()

Figure 3. Shear viscosity vs. shear rate of HYP/PA11 at 200˚C.

3.5. Effect of the Processing Parameters on the Rheological Property

The rheological testing results for the different processing techniques (the extrusion process for the high temperature process, and the Brabender mixer method for the low temperature process) are presented below in Figure 3. The goal of decreasing the process temperature was only realized for 30% HYP/PA11. The Brabender mixer approach was used for the low-temperature compounding, and the process temperature was below the melting point. The rheological properties of the high- and low-temperature compounding are presented in Figure 3.

The low-temperature process compounding has higher shear viscosity compared to the high temperature process; this is because a) during the low-tem- perature process the polymer melting was generated by the high shear rate created during compounding and also because the mixing process was incomplete.

3.6. Effect of the Inorganic Salt Lithium Chloride on the Rheological Properties of HYP Fibre-Reinforced Bio-Based Polyamide Composite

Variations in shear viscosity as a function of the shear rate of HYP/PA11 at various processing temperatures using inorganic salt (LiCl) was realized in order to investigate their effect on the melting point and the rheological properties HYP-fibre?reinforced bio-based PA11 composite. The addition of inorganic salt lithium chloride to PA11 modified it melting point and consequently modified the processing temperature. The rheological test results are presented in Figure 4 and were achieved using the Brabender mixing technique. The processing conditions were 200˚C for the net polyamide without LiCl, 186˚C for 1% LiCl, 182˚C for 2% LiCl, 175˚C for 3%LiCl, 172˚C for 4%LiCl, and 170˚C for 5%LiCl content. In this chapter, LiCl + bio-based PA11 “LiCl + PA11” is referred to as “modified” polyamide 11 for brevity. The rheological test results presented in the figure below are for constant fibre content (30%) and for various process temperature and lithium chloride concentrations.

The variation in the shear viscosity of the HYP/PA11 in function of the rate of shear and lithium chloride concentration was measured and presented. The

![]()

Figure 4. Variation of the viscosity with a function of shear rate of HYP/PA11 at various temperatures.

shearing effects decreased as the salt concentration increased: that is, the modified HYP/PA11 became more non-Newtonian in the higher temperature region for low LiCl concentration. At higher salt concentration the reduction of shear viscosity was more pronounced at intermediate shear rate, while for 175˚C, this reduction is maximized at higher shear rates (from 3000 to 5000 S−1). At low salt concentration and net processing temperature (200˚C) and for low and intermediate shear rate, the flow deformation is challenging. This is due to the fact that the HYP-reinforced PA11 fibres are entangled and agglomerated. At this point, such rheological behavior is called Near-Newtonian. At high shear rate, the shearing effects increased while the effect of temperature and the salt concentration were less pronounced, and flow deformation was mostly dominated by the shearing effect. However, from 3000 to 5000 S−1 all the shear-viscosity variations in function of shear rates followed the same rate of deformation for different salt content and temperature profiles, which corresponds to shear-thinning behavior.

3.7. Effect of HYP Fibre Content on the Rheological Characteristics of Modified Bio-Base (PA11 + 3%Licl) Composite

The effect of fibre content on the rheological characteristics of the HYP-fibre- reinforced modified bio-based polyamide composite was investigated. Figure 5 shows the experimental results for 10%, 20%, and 30% HYPP reinforced modified PA11 “PA11 + LiCl”. These curves are typical of pseudoplastic materials, which show a decrease in viscosity with increasing shear rate. At high fibre content, the material offers higher shear viscosity even for high shear rate. In general, the incorporation of fibres in polymer systems increases the viscosity, which rises further as fibre content is increased.

The difference between 10% and 20% fibre at intermediate and high shear rate is not very significant. At low HYP content, shear viscosity is expected to rise rapidly with increasing concentrations of fibre because of the rapidly increasing interactions between particles as they become more closely packed and entangled. Nevertheless, at very high pulp fibre concentration, random anisotropic structures of the fibres in polymer melts were created, and they increased the

![]()

Figure 5. Shear viscosity vs. shear rate of HYP/PA11 at 200˚C.

shear viscosity. The increase in shear viscosity is found to be more predominant at lower shear rates, where fibre and polymer molecules are not completely oriented.

4. Conclusions

This study demonstrates that it is possible to process HYP fibre with high- thermoplastic-engineering bio-based polyamide. For both processing methods and all formulations, fibres showed a length reduction after compounding process. The observed fibre length reduction using the extrusion process method was lower compared to the fibre length reduction using the Brabender mixer technique. However, the highest fibre reduction was observed for 30% pulp fibre in composite. The low-temperature compounding of HYP/PA11 presents higher shear viscosity compared to the high-temperature compounding for the same rheological parameters; this is because during the process the temperature was low and the mixing and melting were produced by the high shear rate created during compounding process. Experimental testing results from HYP/PA11 for the extrusion processing technique showed a steep decrease in shear viscosity with increasing shear rate at high temperature, and this melt-flow characteristic corresponds to shear thinning behavior in HYP/PA11 and due to the high pulp moisture content which tends to degrade polyamide 11. Results also showed high shear-thinning behavior in modified HYP/PA11 associated with a high degree of crystallinity and pseudoplasticity; this was due to the good dispersion of HYP into PA11 and the orientation of the flexible fibre effects in the direction of the molten PA11.

Acknowledgements

This work was carried out with the support of Mitacs funding, Automotive Partnership Canada

; the University of Toronto and the Ford Motor Company financially supported this study.