Effect of Magnetic Field on the Flow and Heat Transfer in a Casson Thin Film on an Unsteady Stretching Surface in the Presence of Viscous and Internal Heating ()

1. Introduction

During the recent years, study of liquid film flows has received significant attention from researchers due to its possible practical applications in several branches of science and technology. The characteristics of flow and heat transfer in a thin film are extremely useful to understand the coating process, design of different heat exchangers and chemical processing equipments. Similar situations prevail in wire and fiber coating, transpiration cooling, food stuff processing, reactor fluidization, manufacture of plastic and rubber sheets. Primary objective of all applications of extrusion is to maintain the surface quality of the final extrudate as best. It is reported that quality of the product depends on rate of heat transfer at the stretching surface. Hence, study of heat transfer under different thermal conditions shall be helpful to industry. Rassoulinejad-Mousavi and Abbasbandy [1] made an analytical study of forced convection in a circular tube filled with a Darcy-Brinkman-Forchheimer porous medium using spectral Homotopy analysis method. They studied the effect of high values of Forchheimer non-linear term on velocity, temperature and Nusselt number. Rassoulinejad-Mousavi et al. [2] examined the temperature and Nusselt number employing non-thermal equilibrium model in a PPC with permeable walls. Shahabeddin et al. [3] studied the effect of embedding aluminium porous metal foam inside the flow channels of an air-cooled lithium-ion battery to improve its thermal management. Several studies on boundary layer flows in a thin film in Newtonian fluids are available. Andersson et al. [4] explored the flow characteristics of an axisymmetric flow in a Newtonian film. A similar investigation in a liquid film on an unsteady stretching sheet was examined by Usha and Sridharan [5] . Wang [6] investigated the flow characteristics in a Newtonian thin liquid film on an unsteady stretching surface. This study was extended by Dandapat et al. [7] to include heat transfer analysis. Dandapat and Ray [8] [9] explored the flow characteristics in a thin liquid film on a rotating disk taking the effect of cooling and thermocapillarity into account. Study of electrically conducting fluid with heat transfer under the influence of a magnetic field has significant applications in several engineering problems such as re-entry of missiles, space crafts, MHD generators, devices in petroleum industry, nuclear reactors, astro physical flows and the boundary layer control. Gailitis and Lielausis [10] mentioned the effects of Lorentz force on controlling flow of an electrically conducting fluids flowing over a flat plate utilizing an external electromagnetic field with ordering electrodes and permanent magnates with alternating polarity and magnetization. Shirazpour et al. [11] investigated the fully developed flow of a viscous fluid in a porous saturated channel under the influence of Lorentz force using the Darcy-Brinkman model. Analytical solutions are obtained employing Homotopy perturbation method. Rassoulinejad-Mousavi et al. [12] made a theoretical study of the temperature and Nusselt number of a conducting Maxwell fluid through a porous saturated parallel plates channel with different boundary conditions using non-thermal equilibrium model. Lin et al. [13] explored the flow and heat transfer of MHD pseudo-plastic nanofluid in a finite film over a stretching surface with internal heating effects.

The effect of viscous dissipation in heat transfer problems is of importance as it plays significant role as an energy source. The presence of viscous dissipation affects both the temperature and heat transfer rates. Rassoulinejad-Mousavi and Hessameddin [14] explored the effect of quadratic drag on viscous dissipation in a fluid saturated porous medium through a channel bounded by two isothermal or isoflux walls. They observed that the Nusselt number is sensitive to the Forchheimer number. The study of viscous heating in thin film flows has considerable interest. For example, in polymer processing flows like injection modelling or extrusion at high rates and aerodynamic heating in the thin layer around a high speed aircraft, the temperature is observed to increase prominently. Vajravelu et al. [15] carried out a mathematical analysis of the effects of thermo physical properties on the thin film flow of an Ostwald-de Waele liquid over a stretching surface in the presence of viscous dissipation. Abel et al. [16] examined the effect of viscous dissipation on the MHD flow and heat transfer in a liquid film due to a stretching surface. Krishna Jyothi et al. [17] analysed the effect of viscous dissipation on the unsteady boundary layer flow of an incompressible, viscous electrically conducting fluid over a sheet that stretches exponentially in the presence of temperature dependent heat source and thermophoresis with chemical reaction. Sarojamma et al. [18] presented a mathematical model to study the effect of viscous dissipation on the time dependent flow of a Casson fluid due to a stretching sheet embedded in a rotating fluid subject to a uniform magnetic field, with thermal radiation and chemical reaction of nth order.

In industry free surface flows of non-Newtonian fluids in thin films are frequently encountered in industry especially in polymer and plastic fabrication and in coating equipment. It is well known that the process of protective coatings on an extrudate use paints or fluids that are generally non-Newtonian in nature. Studies on film flow of power-law fluids have been examined by several researchers [19] [20] [21] [22] .

However, studies on flows in Casson fluid film are very limited in literature. Casson fluid is a non-Newtonian fluid that can be described as a shear thinning fluid having an infinite viscosity at zero shear rates and a yield stress with no flow below this critical yield value. The empirical model was suggested by Casson [23] while analyzing the flow curves of suspensions of pigments in lithographic varnishes. It is reported that Casson’s constitutive equation described accurately the silicon suspensions [24] , suspensions of bentonite in water [25] and many other industrial polymers. It is well established that when blood flows through small vessels its behavior is satisfactorily explained by modeling it as a Casson fluid. It is reported that blood flow affects the thermal response of living tissues. Craciunescu and Clegg [26] studied the oscillatory flow of heat transfer in blood flow considering the vessels of blood as rigid. Weinbaun et al. [27] and Jiji et al. [28] studied the heat transfer under the influence of vascular microstructure on surface tissue. Cavaliere [29] examined the heat supply to tumors in human beings in the extremities by local perfusion with warm blood. Sarojamma et al. [30] explored the characteristics of heat and mass transfer on the MHD boundary layer flow of a Casson fluid over stretching surface under the influence of a magnetic field. Megahed [31] examined the impact of variable heat flux, viscous heating and velocity slip flow on the heat transfer of a Casson fluid in thin film on a stretching sheet.

In this paper, influence of magnetic field on the thin film flow and heat transfer of a Casson fluid over an unsteady stretching sheet is investigated. The effects of viscous dissipation and internal heating are taken into consideration. Application of suitable similarity variables reduced the governing PDEs into a set of coupled non-linear ODEs for which numerical solutions have been obtained. To the best of knowledge of the authors, influence of transverse magnetic field, viscous dissipation and internal heating on the flow and heat transfer of a Casson fluid film over an unsteady stretching has not yet been studied in literature.

2. Mathematical Formulation

Consider a conducting incompressible non-Newtonian Casson thin film over a heated elastic sheet that emerges from a narrow slit at the origin of the Cartesian coordinate system for investigations as shown schematically in Figure 1. A thin film of uniform thickness  lies on the horizontal stretching sheet. Liquid motion within the film is caused by stretching sheet.

lies on the horizontal stretching sheet. Liquid motion within the film is caused by stretching sheet.

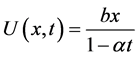

The continuous sheet is parallel to x-axis and moves in its own plane with a velocity

(1)

(1)

where  and

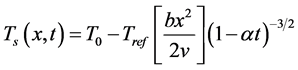

and  are positive constants with dimension per time. The elastic sheet’s temperature

are positive constants with dimension per time. The elastic sheet’s temperature  is assumed to vary with the distance x from the slit as

is assumed to vary with the distance x from the slit as

(2)

(2)

where  is the temperature at the slit,

is the temperature at the slit,  is the kinematic viscocity,

is the kinematic viscocity,  is the con-

is the con-

stant reference temperature such that . A transverse magnetic field

. A transverse magnetic field

is applied to the thin liquid film.

is applied to the thin liquid film.

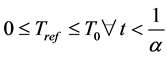

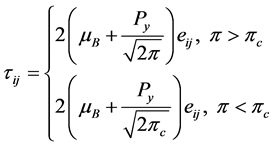

The constitutive of the Casson fluid can be written as [32]

(3)

(3)

where  is the

is the  component of the stress tensor,

component of the stress tensor,  is the plastic dynamic viscosity of the non-Newtonian fluid,

is the plastic dynamic viscosity of the non-Newtonian fluid,  is the yield stress of the fluid,

is the yield stress of the fluid,  is the product of the component of deformation rate with itself, namely,

is the product of the component of deformation rate with itself, namely,  , and

, and ![]() is the

is the ![]() component of deformation rate, and

component of deformation rate, and ![]() is critical value of

is critical value of ![]() based

based

![]()

Figure 1. Physical model and coordinate system.

on non-Newtonian model.

Under these assumptions, the motion of liquid film due to stretching is governed by

![]() (4)

(4)

![]() (5)

(5)

![]() (6)

(6)

where ![]() and

and ![]() are velocity components of liquid in x- and y-directions, T is temperature,

are velocity components of liquid in x- and y-directions, T is temperature, ![]() is kinematic viscosity,

is kinematic viscosity, ![]() is dynamic viscosity,

is dynamic viscosity, ![]() is density,

is density, ![]() is specific heat at constant pressure,

is specific heat at constant pressure, ![]() is the thermal conductivity,

is the thermal conductivity, ![]() is the Casson parameter and

is the Casson parameter and ![]() is electrical conductivity.

is electrical conductivity.

The term Q is heat generation (>0) or absorption (<0) per unit volume which is modeled as [33]

![]() (7)

(7)

where ![]() is temperature-dependent heat generation/absorption and is positive in case of the elastic sheet’s generation of heat and negative in case of the sheet’s absorption of heat from the fluid flow.

is temperature-dependent heat generation/absorption and is positive in case of the elastic sheet’s generation of heat and negative in case of the sheet’s absorption of heat from the fluid flow.

The boundary conditions on the stretching sheet are no slip, no penetration and imposed sheet temperature distribution and they are represented respectively as

![]() (8)

(8)

![]() (9)

(9)

The following similarity transformation are introduced

![]() (10)

(10)

![]() , (11)

, (11)

Also, ![]() is the stream function which automatically assures mass conversation Equation (4). The velocity components are readily obtained as

is the stream function which automatically assures mass conversation Equation (4). The velocity components are readily obtained as

![]() (12)

(12)

where prime denotes differentiation with respect to![]() . Thus the mathematical problem defined through Equations (4)-(9) are transformed to the following non-linear boundary value problem on the finite range of 0 - 1:

. Thus the mathematical problem defined through Equations (4)-(9) are transformed to the following non-linear boundary value problem on the finite range of 0 - 1:

![]() (13)

(13)

![]() (14)

(14)

Subject to the boundary conditions

![]() (15)

(15)

![]() (16)

(16)

where ![]() is the dimensionless measure of unsteadiness,

is the dimensionless measure of unsteadiness, ![]() is Magnetic field parameter,

is Magnetic field parameter, ![]() is Prandtl number and

is Prandtl number and ![]() is Eckert number. Further,

is Eckert number. Further, ![]() denotes the value of the similarity variable

denotes the value of the similarity variable ![]() at the free surface so that the first term of Equation (10) gives

at the free surface so that the first term of Equation (10) gives

![]() (17)

(17)

Since ![]() is an unknown constant, which should be determined, as a whole, from the set of the present boundary-value problem, the rate of change of the film thickness can be obtained as follows:

is an unknown constant, which should be determined, as a whole, from the set of the present boundary-value problem, the rate of change of the film thickness can be obtained as follows:

![]() (18)

(18)

Thus, the kinematic constraint at ![]() given by Equation (9) transforms to the free surface condition (17).

given by Equation (9) transforms to the free surface condition (17).

The parameters of engineering interest in heat transfer problems are Skin friction coefficient ![]() and Nusselt number

and Nusselt number![]() . These parameters characterize surface drag and heat transfer rate and are defined respectively, as

. These parameters characterize surface drag and heat transfer rate and are defined respectively, as

![]() (19)

(19)

![]() (20)

(20)

where ![]() is the local Reynolds number.

is the local Reynolds number.

The coupled ordinary differential Equations (13) and (14) are non linear and exact analytical solutions are not possible. Equations (13) and (14) with the pertinent boundary conditions (15) and (16) are solved numerically by the most efficient numerical shooting technique with fourth order Runge-Kutta algorithm. First we convert these equations into a set of first order equations as follows:

![]() (21)

(21)

![]() (22)

(22)

Corresponding boundary conditions take the form,

![]() (23)

(23)

![]() (24)

(24)

Here ![]() and

and![]() . This warrants the initial values of

. This warrants the initial values of ![]() and

and ![]() and hence suitable guess values are chosen and subsequently integration is performed. A step size of

and hence suitable guess values are chosen and subsequently integration is performed. A step size of ![]() is chosen. It is required to estimate the value of

is chosen. It is required to estimate the value of

![]() satisfying the boundary condition

satisfying the boundary condition![]() . Hence, it is essential to iterate the

. Hence, it is essential to iterate the

value of ![]() until it satisfies this condition with an error of tolerance of 10−6. Accuracy of the present scheme is ensured by comparing the present results, viz., non dimensional thickness of the film

until it satisfies this condition with an error of tolerance of 10−6. Accuracy of the present scheme is ensured by comparing the present results, viz., non dimensional thickness of the film![]() , surface skin friction coefficient

, surface skin friction coefficient ![]() with the corresponding values evaluated by Wang [6] , Abel et al. [34] and Megahed [31] in the absence of magnetic field parameter and

with the corresponding values evaluated by Wang [6] , Abel et al. [34] and Megahed [31] in the absence of magnetic field parameter and ![]() for different values of unsteady parameter. It is pertinent to mention that, as Wang [6] used different similarity variables, the values of

for different values of unsteady parameter. It is pertinent to mention that, as Wang [6] used different similarity variables, the values of ![]() obtained by Wang [6] , shall be same as

obtained by Wang [6] , shall be same as ![]() of the present paper. These values are presented in Table 1 and it is seen that they are an excellent agreement.

of the present paper. These values are presented in Table 1 and it is seen that they are an excellent agreement.

3. Results and Discussion

The coupled non-linear differential Equations (13) and (14) along with the appropriate boundary conditions (15) and (16) are numerically solved employing the BVP4C technique. In order to have a physical insight of the flow in the thin film, numerical computations of flow variables for various sets of governing parameters have been carried out and graphically presented.

Variation of film thickness versus magnetic field parameter for different values of the unsteadiness parameter is plotted in Figure 2. It may be concluded that film becomes thinner for increasing values of![]() . Film thickness reduces rapidly for smaller values of magnetic field, and for higher values, a further reduction is noticed. However, this reduction is steady.

. Film thickness reduces rapidly for smaller values of magnetic field, and for higher values, a further reduction is noticed. However, this reduction is steady.

Behavior of free surface velocity ![]() versus magnetic field for different values of

versus magnetic field for different values of

unsteadiness parameter is highlighted in Figure 3. It is evident from this figure that free surface velocity remains almost uniform for all values of the magnetic field. As unsteadiness parameter ![]() increases the free surface velocity decreases. When

increases the free surface velocity decreases. When ![]() changes its value from 0.8 to 1.2 there is a twofold reduction in free surface velocity.

changes its value from 0.8 to 1.2 there is a twofold reduction in free surface velocity.

![]()

Figure 2. Variation of film thickness ![]() with M.

with M.

![]()

Figure 3. Variation of free surface velocity ![]() with M.

with M.

Figure 4 illustrates the influence of magnetic field and unsteadiness on free surface temperature. It is clear that free surface temperature increases as unsteadiness parameter increases. When ![]() free surface temperature increases monotonically with increasing values of M while for

free surface temperature increases monotonically with increasing values of M while for ![]() it increases linearly with M.

it increases linearly with M.

Figure 5 and Figure 6 are the plots of velocity and temperature respectively for a

![]()

Figure 4. Variation of free surface temperature ![]() with M.

with M.

![]()

Figure 5. Velocity profiles for different values of S.

![]()

Figure 6. Temperature profiles for different values of S.

variation of unsteadiness parameter S. It is observed that velocity distribution in the film decreases monotonically for small values of unsteadiness parameter. As the unsteadiness parameter takes higher values fluids gets accelerated and hence higher velocities occur. Films become thinner for increasing values of unsteadiness parameter. When unsteadiness parameter S = 1.4, film thickness is reduced by two and half times than that of the film corresponding to S = 0.8. Fluid in the film gets cooled as unsteadiness parameter increases. However, reduction in the temperature is small.

Figure 7 and Figure 8 highlight the impact of strength of magnetic field on the velocity and temperature distributions in the film. In the absence of magnetic field, velocity steadily decreases in the film. Presence of magnetic field causes a rapid reduction of velocity in the vicinity of the boundary due to the action of Lorentz force which resists the fluid flow. Temperature shows an opposite behavior with a gradual enhancement in temperature for increasing values of the magnetic parameter M. For all values of M, temperature assumes its minimum value at the free surface.

Figure 9 and Figure 10 illustrate the influence of non-Newtonian nature of the fluid through the Casson parameter on velocity. It is observed that velocity in the vicinity of the boundary becomes a constant function of the Casson parameter. However, a significant reduction in the velocity in the film is observed away from the boundary for increasing values of![]() . Reduction in the velocity might be due to the non-Newtonian nature of the fluid as increase in Casson parameter corresponds to an increase in the plastic dynamic viscosity of the fluid. Film thickness also gets reduced for higher values of

. Reduction in the velocity might be due to the non-Newtonian nature of the fluid as increase in Casson parameter corresponds to an increase in the plastic dynamic viscosity of the fluid. Film thickness also gets reduced for higher values of![]() . However, increasing values of

. However, increasing values of ![]() raise the temperature.

raise the temperature.

Figure 11 presents the plots of temperature for a variation in Prandtl number. It is revealed that temperature drops from its higher value on the wall to its minimum value

![]()

Figure 7. Velocity profiles for different values of M.

![]()

Figure 8. Temperature profiles for different values of M.

on the surface. For higher values of Pr, temperature falls rapidly near the boundary. When ![]() it attains zero temperature at

it attains zero temperature at![]() . Higher values of

. Higher values of ![]() indicate that thermal conductivity of the corresponding fluid is lower.

indicate that thermal conductivity of the corresponding fluid is lower.

Figure 12 illustrates the impact of Eckert number on temperature. Temperature plots

![]()

Figure 9. Velocity profiles for different values of![]() .

.

![]()

Figure 10. Temperature profiles for different values of![]() .

.

indicate that increasing values of ![]() heat up the fluid in the film resulting in higher temperatures. This enhancement is due to internal heating in the fluid layers. In particular near the boundary when

heat up the fluid in the film resulting in higher temperatures. This enhancement is due to internal heating in the fluid layers. In particular near the boundary when ![]() there is an over shot of the temperature. As illustrated in Figure 13, the presence of heat source

there is an over shot of the temperature. As illustrated in Figure 13, the presence of heat source![]() , increases temperature while

, increases temperature while

![]()

Figure 11. Temperature profiles for different values of Pr.

![]()

Figure 12. Temperature profiles fordifferent values of Ec.

in the presence of heat sink ![]() the behavior of the temperature of fluid in the film is the exact opposite of that observed in case of heat source

the behavior of the temperature of fluid in the film is the exact opposite of that observed in case of heat source![]() .

.

Surface drag coefficient and Nusselt number on the surface for different variations of

![]()

Figure 13. Temperature profiles fordifferent values of![]() .

.

the flow parameters are tabulated in Table 2. Skin friction coefficient is found to enhance with elapse of time. Rate of heat transfer at the boundary is seen to decrease with increase in the unsteadiness parameter which is in conformity with the behavior of the temperature with unsteadiness parameter. Increasing values of Casson parameter reduce surface drag marginally due to smaller velocities. Rate of heat transfer is found to be small for variation in Casson parameter. Due to stronger magnetic fields the surface drag coefficient is significantly reduced. The Lorentz force is observed to favour the heat transfer. Table 3 presents the Nusselt number for different values of Pr, Ec and![]() . Increase in Prandtl number leads to an enhancement of the temperature gradient. Eckert number has a prominent impact in enhancing the rate of heat transfer.

. Increase in Prandtl number leads to an enhancement of the temperature gradient. Eckert number has a prominent impact in enhancing the rate of heat transfer.

4. Conclusions

In this investigation, effect of viscous dissipation and velocity slip on the characteristics of flow and heat transfer in a thin Casson liquid film resting on an unsteady stretching sheet under the influence of a uniform transverse magnetic field and thermal radiation is studied. The partial differential equations governing the flow and energy are transformed into a set of ordinary differential equations by employing appropriate similarity transformations. These ODEs are later solved numerically using shooting technique along with the efficient Runge-Kutta method. Results of the present analysis are validated with available data in literature and are found to be in excellent agreement. The following are some of the salient features of the investigation:

Ø Film thickness is found to decrease as unsteady parameter increases. Qualitatively

![]()

Table 3. Variation of ![]() for various values of Pr, Ec and

for various values of Pr, Ec and![]() .

.

similar behavior is noticed for increasing values of magnetic field and Casson parameters.

Ø Free surface velocity is found to be a decreasing function of the magnetic field parameter.

Ø Temperature distribution in the thin film is enhanced with increase in magnetic field strength and non-Newtonian nature of fluid.

Ø Viscous heating enhances rate of heat transfer.

Acknowledgements

The authors express their sincere thanks to the editor and referee for their valuable comment and suggestions, which lead to a significant improvement of the paper.