An Optimal Control Theory Based Analysis of Brushless DC Motor Drive ()

Received 5 May 2016; accepted 15 May 2016; published 31 August 2016

1. Introduction

Presently, consumers demand for lower energy costs, higher efficiency, better performance, reduced acoustic noise and more convenient features. The traditional technologies like DC motor and AC motor cannot meet these demands. Hence, motor manufactures are gravitating towards Brushless Direct Current (BLDC) motor. The use of the BLDC motor in these applications is becoming very common due to the features of high efficiency, high flux density per unit volume and high power density due to the absence of field winding. In addition, the absence of brushes leads to high reliability, low maintenance requirements and low electromagnetic interference problems [1] [2] . This drive can be used for variable speed applications like Electrical Vehicles, Robotics, etc.

Due to change in load variations, BLDC motor exhibits oscillations in speed response and hence the stability of the system gets affected. The stability issues can be recovered by two ways, namely reducing the gain of speed controller and regulating output method [3] - [5] . But reducing the gain increases the oscillations and decreases the system performance. The regions of instability occur due to changes in the reference input command. Because of oscillations in the output of BLDC motor, it cannot achieve precise speed control. In the next method of regulating the system output modification cannot achieve the time optimal operation [6] - [8] . In the classical design method of control systems, the designer is given a set of specifications in time domain or in frequency domain with the system configuration. In practice, it may not be possible to satisfy all the desired specifications [9] - [11] . The optimal control design is aimed at obtaining a best possible system of a particular type with respect to a certain performance index or design criterion. The optimal control problem of systems has always been the key focus of control fields in the past several decades. The optimal control approaches are mostly based on linearization methods or numerical computation methods [12] [13] .

The optimal control design is aimed to obtain a best possible system of a particular type with respect to a certain performance index. In the optimal control design, the performance index replaces the conventional design criteria. A transfer function for the BLDC drive is derived in this paper. In this paper, for digitally PWM controlled BLDC motor drive, the optimal control system is designed. To achieve this optimization, the state and control variables are formulated in this paper. Based on optimal control theory, the BLDC performance characteristics close to the optimal control system are synthesized.

2. Digital PWM Control of BLDC Motors

By changing the applied voltage across the motor phases, the speed of BDC motor can be controlled. This is achieved by utilizing pulse amplitude modulation, PWM or hysteresis control. Another method of speed control involves sensorless techniques. Figure 1 shows the block diagram for digital PWM control for a BLDC motor drive system. The derivation of this model is based on the assumption that the induced currents in the rotor due to stator harmonic fields are neglected and the iron and stray losses are also neglected [4] .

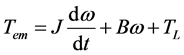

The torque equation is given by,

(1)

(1)

where Tem, ω(t), B, J and TL denote electromagnetic torque, rotor angular velocity, viscous friction constant, rotor moment of inertia and load torque respectively.

(2)

(2)

![]()

Figure 1. Block diagram for digital PWM control for a BLDC motor drive system.

(3)

(3)

(4)

(4)

where Kt = torque constant and I = average current. For the purpose of analysis, the digital controller was considered equivalent to a proportional controller with high gain and saturation.

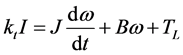

From the above equations it is possible to derive the transfer function

(5)

(5)

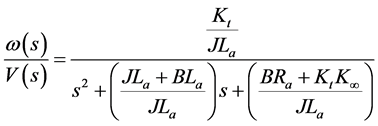

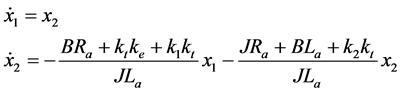

The state variable equation for this BLDC drive is given by

(6)

(6)

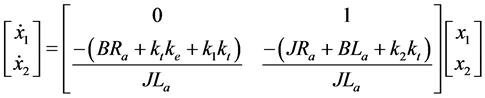

Arranging in matrix form, the following equations are obtained

(7)

(7)

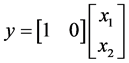

The output equation is given by,

(8)

(8)

3. State Variable Feedback

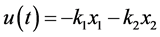

The design of a state feedback BLDC motor control system is based on a suitable selection of a feedback system structure. If the state variables are known, then they can be utilized to design a feedback controller so that the input becomes u = kx. It is necessary to measure and utilize the state variables of the system in order to control the speed of the BLDC motor. This design approach of state variable feedback control gives sufficient information about the stability of the BLDC drive system. Feedback control system will be chosen so that,

(9)

(9)

Then Equations (6) & (7) become,

(10)

(10)

Arranging in matrix form the following state equation is obtained

(11)

(11)

This is in the form

where

(12)

(12)

Let k1=1 and determine a suitable value for k2 so that the performance index is minimized.

(13)

(13)

![]() (14)

(14)

![]() (15)

(15)

Completing matrix multiplication, addition and solving the following are obtained

![]() (16)

(16)

![]() (17)

(17)

![]() (18)

(18)

![]() (19)

(19)

To minimize as a function of k2

![]() (20)

(20)

Therefore,

![]() (21)

(21)

![]() (22)

(22)

![]() (23)

(23)

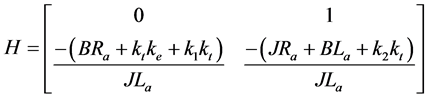

The system matrix H obtained for the compensated system is,

![]() (24)

(24)

The feedback control signal is obtained as,

![]() (25)

(25)

This optimal controlled BLDC drive system results in a minimum value for the performance index. Also, the control law given by Equation (25) yields optimal result for any initial state under the given performance index. This design based on the quadratic performance index yields a stable control system for the BLDC drive system.

4. Optimal System with Control Energy Considerations

This section considers the expenditure of control signal energy for the BLDC drive system. To account for the expenditure of the optimal energy of the performance index ![]() is chosen where λ is the scalar weighting factor and I = identity matrix. Table 1 gives parameters of BLDC drive systems. We will choose a feedback control system so that,

is chosen where λ is the scalar weighting factor and I = identity matrix. Table 1 gives parameters of BLDC drive systems. We will choose a feedback control system so that,

![]() (26)

(26)

Therefore the matrix Q is

![]() (27)

(27)

Let,

![]() (28)

(28)

![]() (29)

(29)

![]() (30)

(30)

To simplify the algebra without any loss, let ![]()

![]() (31)

(31)

![]() (32)

(32)

![]() (33)

(33)

![]() (34)

(34)

![]() (35)

(35)

To obtain minimum performance index, set![]() , following equations are obtained

, following equations are obtained

![]() (36)

(36)

where

![]() (37)

(37)

![]() (38)

(38)

![]() (39)

(39)

![]() (40)

(40)

![]() (41)

(41)

When![]() , Solving the above equations we get,

, Solving the above equations we get,

![]() (42)

(42)

Applying Lin’s Method the above equation becomes

![]() (43)

(43)

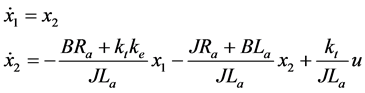

5. Quadratic Optimal Control

This section discusses about the design of a stable control system for BLDC drive based on quadratic performance indexes. The system design will be stable by using the quadratic optimal control scheme has the main advantage except in the case where the system is not controllable. The matrix “P” is determined from the solution of the matrix Riccatti equation. This optimal control is called the Linear Quadratic Regulator (LQR) [10] [11] . The optimal feedback gain matrix k can be obtained by solving the following Riccatti equation for a positive-definite matrix “P”.

![]() (44)

(44)

Let,

![]() (45)

(45)

![]() (46)

(46)

Solving we obtain the following three equations

![]() (47)

(47)

![]() (48)

(48)

![]() (49)

(49)

![]() (50)

(50)

Solving these three equations we get,

![]() (51)

(51)

The optimal feedback gain matrix

![]() (52)

(52)

![]() (53)

(53)

![]() (54)

(54)

This control signal yields an optimal result for any initial state under the given performance index. Figure 2 shows the block diagram for optimal control of the BLDC drive system.

6. Conclusion

To achieve the desired system response, the BLDC drive system had designed with state variable feedback. Also the performance index value is minimum for BLDC drive which was designed by optimal control. In accordance with the expenditure of energy and resources, the control signal is often included in the performance integral. From the foregoing analysis, the value of K2 is obtained as 1.0149 so that the performance index is minimized. The minimum value of performance index is obtained as 1.47. This optimal controlled BLDC drive system results in a minimum value for the performance index. Also, the control law given by Equation (54) yields optimal

![]()

Figure 2. Optimal control of the BLDC drive system.

results for any initial state under the given performance index. This design based on the quadratic performance index yields a stable control system for the BLDC drive system.