Comparative Studies between Physicochemical Properties of White Waxy Wheat Flour and Glutinous Rice Flour ()

Subject Areas: Agricultural Science

1. Introduction

Most of wheat planted in the world is common wheat which has 20% - 30% amylose and 70% - 80% amylopectin. It is called glutinous wheat where there is no amylose or lower amylose content (<1%) [1] . There are glutinous rice, corn and sorghum grain crop from natural variation but not glutinous wheat. All of waxy wheat is artificial cultivation. Waxy (amylose-free) wheats (Triticum aestivum L.) have been developed via classical breeding and genetics [2] . There are particular physicochemical properties in waxy flour by more than 90% amylopectin and particular mucedin. Many uses have been suggested for waxy wheat, including a source of blending flour to improve shelf-life stability, processing quality or palatability of baked and sheeted wheat products [3] [4] .

Waxy wheat breeding programs are underway in a number of countries [5] [6] , but commercial cultivation of waxy wheat, at least in China, has yet to be initiated. At present, most waxy food product in market is made from glutinous rice flour which has lower protein content especially lack of the essential amino acids for human―lysine. It is significant to use waxy flour as substitute goods for it has particular gluten protein comparing with glutinous rice flour. There are potential applications in the waxy wheat including the industrial uses, Asian noodle making, and specific food production and extending the shelf-life of baked products [7] . Thus, it is important to determine the waxy flour properties. The goal of this study was to establish a theoretical basis for waxy food product by comparing the difference of properties between white waxy wheat flour and glutinous rice flour.

2. Materials and Methods

2.1. Test Materials

White waxy wheat: the new waxy wheat bred in Shandong Agricultural University. Glutinous rice flour purchased from a local market in

Shandong

province

of

China

was sieved into a particle size of 100 μm. α-amylase with enzyme activity 2000 U/g. Glucamylase with enzyme activity 120,000 U/g. Analytically pure sodium acetate, benzoic acid, glacial acetic acid, sodium potassium tartrate, sodium hydroxide, 3,5-dinitrosalicylic acid, phenol, sodium sulphite and glucose.

2.2. Preparation of Millet Flour

We choose no mildew and no sprout wheat, after 80 mesh sieve to remove the impurities. Millet grains were thoroughly cleaned by removing unviable seeds and then washed with cold tap water and thoroughly rinsed with distilled water, then the water was drained and grains were solar dried, milled,

2.3. Solubility and Swelling Power

Solubility and swelling power of white waxy wheat flour and glutinous rice flour were determined as follows. Add 1 g white waxy wheat flour and glutinous rice flour to centrifuge tube and transfer purified water to a 50 mL volumetric flask. Then heated at the temperature of 50˚C, 60˚C, 70˚C, 80˚C, 90˚C in electronic oscillator for 30 min, after this, this samples should be centrifuge at 3000 r/min for 20 min, water bath the supernate and dry to constant weight at 105˚C. At last, the solubility and swelling power can be calculated.

2.4. Paste Retrogradation Characteristics

Paste retrogradation characteristic of white waxy wheat flour and glutinous rice flour were analyzed according to GB/T24853―2010 [8] .

2.5. Paste Transparency, Freezing and Thawing Stability

Paste transparency, freezing and thawing stability of white waxy wheat flour and glutinous rice flour were analyzed according to the method described by Ma et al. [9] .

2.6. Water-Retaining Capacity

Water-retaining capacity of white waxy wheat flour and glutinous rice flour were measured according to the

method of AACC 56-20 with some modifications. 10 mL distilled water was added into a centrifuge tube A (g) containing 0.1 g sample, heated at a specific temperature (70˚C, 80˚C, 90˚C) in a water bath for 1 h, centrifuged at 3000 r/min (TG1650-WS, Shanghai) for 20 min. Discarded the supernatant and weigh the gel B (g). The water-retaining of flour was calculated by

(1)

(1)

2.7. Digestibility

Digestibility of white waxy wheat flour and glutinous rice flour were determined according to the methods described by Miao et al. [10] . The glucose standard curve is presented in Figure 1.

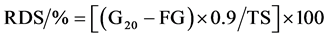

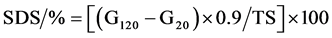

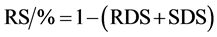

The digestibility of white waxy wheat flour and glutinous rice flour were examined by rapid digestive starch (RDS), slow digestive starch (SDS) and resistant starch (RS) using the following equations:

(2)

(2)

(3)

(3)

(4)

(4)

where G20 is the total glucose content (mg) after enzyme hydrolysis 20 min; TS is the total starch content (mg) of sample; FG is the glucose content (mg) before enzyme hydrolysis; G120 is the total glucose content (mg) after enzyme hydrolysis 120 min.

2.8. Freezing and Thawing Stability

6% (W/V) soluble starch was prepared by adding 50 mL distilled water into sample 3.00 g, gelatinized by heating in a water bath for 30 min, then cooling down to room temperature. A certain amount of sample was added into a centrifuge tube, frozen at −18 - −20˚C in a refrigerator for 24 h, unfroze in room temperature, centrifuged at 3000 r/min (TG1650-WS, Shanghai) for 20 min. Discarded the supernatant and weigh the precipitate. The water segregation rate (better Freezing and thawing stability with lower water segregation rate) of flour was calculated by the following equations:

Water segregation rate = (soluble starch weigh − precipitate weigh)/soluble starch weigh × 100%.

2.9. Paste Retrogradation Characteristics

Paste retrogradation characteristics of white waxy wheat flour and glutinous rice flour were determined according to the methods described by Ding [11] .

All of determinations were done triplicates and calculated the averaged. SPSS software version 16.0 and sigma plot 10.0 was used to evaluate the analysis (ANOVA) and draw the figures, respectively.

3. Results and Discussion

3.1. Solubility and Swelling Power Comparison between White Waxy Wheat Flour and Glutinous Rice Flour

Interaction between starch and water can be reflected by solubility. As shown in Figure 2, both the solubility of two samples increased with the increasing temperature. It is due to the liquid water associate together loosely with hydrogen bond, the proportion of single molecule water increase with higher temperature, then quantity of the starch molecule which participate in dehydration increase accordingly [12] . The solubility of white waxy wheat flour is lower than that of glutinous rice flour when the temperature is lower than 60˚C and whereas in the temperature higher than 60˚C. The possible reason is that wheat gluten reticular structure formed by water absorption of gliadin and glutenin in flour hindered the starch dissolution. Water absorbing capacity of starch suspension liquid in the gelatinization and water-retaining capacity centrifuged under a certain conditions can be reflected by swelling properties which also could be describe the gelatinization properties of starch. It can be observed from Figure 3 that the swelling power of white waxy wheat flour and glutinous rice flour increases with temperature rise.

3.2. Gelatinizatin Properties

A number of factors contributed to the gelatinizatin properties such as source, particle morphology, grain diameter, relative molecular weight and the proportion between amylose and amylopectin. Variations were obvious between the gelatinizatin properties of white waxy wheat flour and glutinous rice flour as shown in Table 1. There are higher peak viscosity, trough viscosity, breakdown, final viscosity, setback and peak time in

![]()

Figure 2. Solubility of white waxy wheat flour and glutinous rice flour.

![]()

Figure 3. Swelling power of white waxy wheat flour and glutinous rice flour.

![]()

Table 1. Rapid viscosity analyzer of white waxy wheat flour and glutinous rice flour.

glutinous rice flour, indicating it has better water combining capacity, fast rate and large extent of decay, poor anti-shearing and heat-resistant quality, and better gelatination after cooling while worse ageing resistance in glutinous rice flour. Compared with it, white waxy wheat has lesser breakdown and setback, indicating that the swelled starch has better particle strength which not easy to break, better anti-shearing and heat-resistant quality, worse gelatination but better ageing resistance.

As far as the results that white waxy wheat has higher pasting temperature than glutinous rice flour, it may be mainly influenced by the molecular weight of white waxy wheat is much bigger than that of glutinous rice flour.

3.3. Paste Transparency

Swelling and distribution degree of starch granule in water were reflected by transparency. Transparency is higher with unanimous distribution and strong hydroscopicity, whereas transparency is lower by the reflection, refraction and diffusion of the light passed through due to the insufficient swelling, uneven distribution or retrogradation resulting in flocculation of starch in solution [13] . Transparency is one of the important external characteristics of starch paste which relates directly to the appearance and use of starch product, and then affects the acceptability of product [14] .

It can be seen in Table 2, the transparency of white waxy wheat flour significantly lower than that of glutinous rice flour. It maybe due to there were a small quantity of bran in the wheat flour, which had reflection, refraction and diffusion of the light passed through, resulting in lower transparency. During the storage period, the both transparency of two samples reduced, maybe related to the retrogradation which has negative correlation with transparency. Compared with white waxy wheat flour, glutinous rice flour has worse stability transparency attributed to it has relative smaller molecular weight easily formed network structures such as hydrogen bond then reduce the transparency.

3.4. Water-Retaining Capacity

Water-retaining capacity has a significant effect on shape and structure preserving of white waxy wheat flour and glutinous rice flour food product. As shown in Figure 4, there is no significant difference between tow samples at room temperature while white waxy wheat flour has lower water-retaining capacity than that of glutinous rice flour at higher temperature. Both of them increase with increasing of the temperature. The reason of water-retaining capacity increase at high temperature should be that starch lose crystallinity for high temperature, more hydrone permeate into and hydrate freely with starch molecules nearby microcrystal resulted in increase of water-retaining capacity.

3.5. Freezing and Thawing Stability

Frozen foods should maintain original structure after storing in cold condition or freezing and thawing many times. So the starch paste used in frozen foods were required good freezing and thawing stability which is better with more freezing and thawing times and lower water segregation rate. Water precipitation appeared until in the second time of white waxy wheat flour and glutinous rice flour’s unfreeze procedure (Figure 5). The higher water segregation rate of white waxy wheat flour after same freezing and thawing times than that of glutinous rice flour indicated that it had a better freezing and thawing stability than glutinous rice flour.

3.6. Digestibility

Englyst et al. [15] felled starch into three categories by the character of digestion and absorption in the human

![]()

Table 2. Paste transparency of white waxy wheat flour and glutinous rice flour.

![]()

Figure 4. Water-retaining capacity of white waxy wheat flour and glutinous rice flour.

![]()

Figure 5. Freezing and thawing stability of white waxy wheat flour and glutinous rice flour.

body: Rapidly digestible starch (RDS), slowly digestible starch (SDS) and resistant starch (RS).

As shown in Table 3, white waxy wheat flour had higher RDS, SDS and lower RS than glutinous rice flour which indicating that white waxy wheat flour is easily digestible.

3.7. Paste Retrogradation Characteristics

The heat absorbed in crystal melting and gave off in crystal formation can be measured by DSC. The content of crystal was determined by caloric content comparison indicating that higher caloric content of samples means higher crystallinity they had. Retrogradation is a reaction that takes place in gelatinized starch when the amylose and amylopectin chains realign themselves, causing the liquid to gel. The change trend of thermodynamic parameters such as the initial temperature T0, the peak temperature Tp, the finishing temperature Tc and the caloric content ΔH were shown in Table 4. The results show that the T0 and Tc of both samples are approximately same, Tp and enthalpy ΔH of white waxy wheat flour were higher than that of glutinous rice flour respectively during the gelatinizing phase possibly because white waxy wheat flour had higher particle crystallinity.

None retrogradation of white waxy wheat flour and glutinous rice flour was detected in the first and the third day. White waxy wheat flour had lower retrogradation characteristics than glutinous rice flour around the same time declaring that white waxy wheat flour has good ageing resistance.

4. Conclusions

1) Both the solubility of white waxy wheat flour and glutinous rice flour increased with the increasing temperature. White waxy wheat flour had higher solubility and lower water-retaining capacity and paste transparency than that of glutinous rice flour at high temperature.

2) Obvious differences of gelatinization parameters were detected between white waxy wheat flour and glutinous rice flour. Glutinous rice flour had higher peak viscosity, trough viscosity and final viscosity while white waxy wheat had lesser breakdown and setback. The results show that the swelled white waxy wheat starch has better particle strength which is not easy to break, better anti-shearing, heat-resistant quality and ageing resistance.

![]()

Table 3. Content of digestible starch of white waxy wheat flour and glutinous rice flour.

![]()

Table 4. Pasting and retrogradation thermodynamics parameters of white waxy wheat flour and glutinous rice flour (DSC).

3) White waxy wheat flour had higher RDS, SDS and lower RS than glutinous rice flour which indicating that white waxy wheat flour was easily digestible. White waxy wheat flour had better freezing and thawing stability, anti-retrogradation ability and stronger ageing resistance.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant nos. 91217308, 90917015, and 90717006).

NOTES

*Peng Wu and Xiansheng Zhang contributed equally to this work as corresponding authors.