Algorithm Design and Simulation of the Urban Rail Turn-Back Capacity Based on CBTC ()

1. Introduction

With the development of urban rail transit signal system, the bottleneck of the rail transit capacity mainly appears at the turn-backstage [1] . Therefore, many scholars analyze and research the turn-back capacity of urban rail transit.

Zhang Guobao [2] proposed the method that calculated and verified turn-back capacity by graphic method; Jiang Fan et al. [3] provided the basic principle of turn-back capacity simulation and the corresponding algorithm process; Maon Baohua [4] studied the train running time during turn-back process based on traction calculation. The value of turn-back capacity is referenced.

However, those studies are lack of considering the influence of turn-back capacity by signal system, especially, most of the new urban rail transit using the CBTC signal system nowadays. Therefore, there is certain reference value to analyze and study the characteristics of the turn-back process and capacity in CBTC system.

2. Train turn-Back Capacity Analysis

There are two turn-back methods in urban rail transit. One is turn-back after station and the other is turn-back before station, as shown in Figure 1.

There are mainly three stages in the turn-back process:

1) If the method is turn-back after station, the stage is that head train leaves platform B to the turn-back zone, clearing switch 101; if the method is turn-back before station, the stage is that head train leaves platform C and clears switch 102;

2) If the method is turn-back after station, the stage is that head train exchange cab; If the method is turn-back before station, the stage is that the following train entry into platform C;

3) If the method is turn-back after station, the stage is that following train entries into platform B and starts to leave; if the method is turn-back before station, the stage is that the following train’s dwell time expires and it starts to leave.

So, there are mainly three factors needed to be considered to calculate the minimum turn-back interval time based on the analysis.

1) Headway between the consecutive trains;

2) Running time in the turn-back process;

3) The signal system response time, mainly including the dwell time, switch moving time, and driver switching cab time etc.

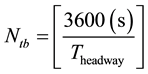

Therefore, turn-back capacity refers to the maximum trains every hour in the turn-back station [5] . We can calculate the turn-back capacity using the following formula.

―number of trains in every hour;

―number of trains in every hour;

―time interval between the consecutive train;

―time interval between the consecutive train;

―achieving the nearest integer.

―achieving the nearest integer.

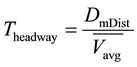

2.1. Headway Time Interval Analysis

The headway between the consecutive train is mainly affected by the signal system. For example, according to

IEEE 1474.1 standard [6] , the headway mainly follows the braking distance to ensure the safety in CBTC system, as shown in Figure 2.

Therefore, headway time calculates using the following formula:

―minimum safety distance between trains;

―minimum safety distance between trains;

―average speed running in the safety distance.

―average speed running in the safety distance.

2.2. Running Time in Turn-Back Process

As shown in Figure 1, it describes the train at various stages of the turn-back process. In order to calculate the all stages running time about turn-back, this paper proposes an algorithm to simulate the train running process, including the train various states, such as starting state, acceleration state, cruise state, brake state etc., based on train characters. Figure 3 describes the simulated speed-distance graph in turn-back process stage.

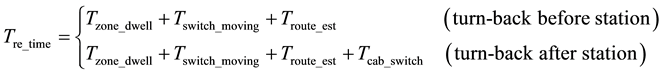

2.3. Signal System Reaction Time

The reaction time mainly include the train dwell time in turn-back zone , the switch moving time

, the switch moving time , the train route establishment time

, the train route establishment time  and the driver switch cab time

and the driver switch cab time  etc. In turn-back before station mode, the train dwells at turn-back station. At the same time, the driver can complete the work of switching cab. So exclude the switch cab time in turn-back before station mode. So the signal reaction time equal to the following formula.

etc. In turn-back before station mode, the train dwells at turn-back station. At the same time, the driver can complete the work of switching cab. So exclude the switch cab time in turn-back before station mode. So the signal reaction time equal to the following formula.

3. Train Turn-back Capacity Algorithm Design

It’s necessary to precisely simulate above times when calculating the train turn-back interval through the above

![]()

Figure 2. Safety braking distance between consecutive trains.

analysis. At the same time, when calculating the minimum turn-back interval, also need to consider the consecutive train interact each other. For example, the ahead train leaves turn-back station into the turn-back zone, the following train can’t enter turn-back station because the condition isn’t valid for it to create route.

Therefore, we need to determine the turn-back capacity following the interlock relationship between the consecutive trains. It designs the main flow chart of algorithm (Figure 4).

Mentioned formulas in the algorithm flow chart as follows:

![]()

4. Simulation System Design

Through the above process analysis and related algorithm design, it develops a general train turn-back capacity simulation system based on CBTC (TBSim), the calculation process as shown in Figure 5.

A turn-back station in Beijing as an example, Figure 6(a). It’s turn-back station, combining the actual line data, the turn-back path and the information such as vehicle parameters, as show in Tables 1-3. Through the use of TBSim, it gets the simulation results as shown in Figure 6(b) and Table 4.

From above result, we can know the turn-back station turn-back time interval is

![]()

The station turn-back capacity is

![]()

![]()

Figure 5. The TBSim system calculation process.

![]()

![]() (a) (b)

(a) (b)

Figure 6. (a) Turn-back simulation station in Beijing; (b) Turn-back process based on events.

![]()

Table 1. Civil data of turn-back simulation station.

5. Conclusion

To sum up, this article proposes the algorithm about calculation metro’s turn-back capacity in CBTC signal system and establishes the turn-back capacity simulation system (TBSim). Finally, it analyses the actual platform turn-back capacity by the tool of TBSim, showing that the algorithm and the simulation system have certain feasibility and practicability value. It can analyze and describe the turn-back capacity of platform accurately during the planning and design stage using the algorithm.

Acknowledgements

The authors gratefully acknowledge the support of the following projects:

The Training Project of Youth College Teachers of Shanghai Municipal Education Commission (ZZGJD13042).