1. Introduction

Agaricus blazei Murill was considered one of the most important edible and medicinal mushrooms [1] . We also called it Agaricus brasiliensis. According to the research, Agaricus blazei Murill has certain medicinal function and health care function [2] , such as immune-enhancement, oxidation resistance, lower blood lipids et al. [3] . So the study on Agaricus blazei Murill shows good application future [4] . Now it has realized the artificial cultiva- tion of Agaricus blazei Murill but it was still difficult to cultivate it, while the limitations of time and yield can- not meet the market demand. Research showed that there were no essential difference between fruiting bodies and mycelium of Agaricus blazei Murill in the composition of polysaccharide [5] . Besides liquid fermentation has much more advance than solid fermentation. Firstly, products have a steady good quality and yield well; se- condly, the fermentation conditions are easy to control; thirdly, the cycle of the liquid fermentation is shorter than solid fermentation [6] .

The experiment was to study the effects on different conditions submerge fermentation of Agaricus blazei Murill, which based on the optimization of submerged cultivation with biomass and production of bacterial extracellular polysaccharides as experimental indicators. The optimal submerge fermentation conditions of Aga- ricus blazei Murill were obtained through the experiment.

2. Materials and Methods

2.1. Materials

The Agaricus blazei Murill strains were brought from Culture Collection Center of Huazhong Agricultural Uni- versity.

2.2. Medium

Solid culture medium

Potato 200 g, Glucose 20 g, KH2PO4 2 g, MgSO4. 5H2O 0.2 g, Agar 20 g, H2O 1000 mL, pH 6.5 - 7.5

Liquid seed medium

Potato 200 g, Glucose 20 g, KH2PO4 2 g, MgSO4. 5H2O 0.2 g, H2O 1000 mL, pH 6.5 - 7.5

Liquid fermentation medium

Potato 200 g, Bran 50 g Glucose 20 g, KH2PO4 2 g, MgSO4. 5H2O 0.2 g, H2O 1000 mL, pH 6.5 - 7.5

Sugar 57.5 g/L, Industrial corn pulp 2.05 g/L, KH2PO4 2 g, MgSO4. 5H2O 0.2 g, H2O 1000 mL

2.3. Experimental Method

At the end of fermentation, centrifuge the fermentation solution under 2500 r/min. Distilled water was used to wash the mycelium for 4 - 5 times, then dried the mycelium pellet in the air drier at 60˚C. DNS method [7] [8] , Phenol-Sulfuric acid method [9] - [11] , Roe colorimetric method [12] was used to determine sugar, total sugar and sucrose. The content of the extracellular polysaccharide is equal to total sugar minus sucrose and reducing sugar.

2.4. Agaricus blazei Murill Liquid Fermentation Process

The shaker was used during the process of the liquid fermentation of Agaricus blazei Murill. pH, temperature, rotational speed, inoculation amount are the four factors that affect the submerge fermentation of Agaricus bla- zei Murill. During the liquid fermentation of Agaricus blazei Murill, we should control the four factors. This ensured the optimum fermentation conditions. The dry weight of biomass and extracellular polysaccharide were taken as the detection index.

2.5. Single Factor Experiment

Under the aseptic conditions, seed solution of Agaricus blazei Murill was inoculated in 200 ml flasks which included 100 ml liquid fermentation medium, the inoculum size was 5% and the pH of the medium respectively were 5.5, 6.0, 6.5, 7.0 and 8. Then the flasks were cultured 3 days in constant temperature oscillation shaker, the culture temperature was 25˚C and the rotating speed was 150 r/min.

Under the aseptic conditions, seed solution of Agaricus blazei Murill was inoculated in 200 ml flasks which included 100 ml liquid fermentation medium, the inoculum size was 5%. Then the flasks were cultured 3 days in constant temperature oscillation shaker, the culture temperature was 25˚C and the rotating speed respectively were 90 r/min, 120 r/min, 150 r/min, 180 r/min and 210 r/min.

During the single factor experiment of inoculum size, the 5 experiment gradient were adopted in experiment, which were 4%, 6%, 8%, 10% and 12%. Under the aseptic conditions, seed solution of Agaricus blazei Murill was inoculated in 200 ml flasks which included 100 ml liquid fermentation medium, the inoculum size respec- tively were 4%, 6%, 8%, 10% and 12%. Then the flasks were cultured 3 days in constant temperature oscillation shaker, the culture temperature was 25˚C and the rotating speed was 150 r/min. The experiment indexes were cell dry weight and extracellular polysaccharide content.

During the single factor experiment of culture temperature, the 5 experiment gradient was adopted to deter- mine optimal temperature in experiment, which were 19˚C, 22˚C, 25˚C, 28˚C and 31˚C. Under the aseptic con- ditions, seed solution of Agaricus blazei Murill was inoculated in 200 ml flasks which included 100 mL liquid fermentation medium, the inoculum size was 5%. Then the flasks were cultured 3 days in constant temperature oscillation shaker, the rotating speed was 25˚C and the culture temperature respectively were 19˚C, 22˚C, 25˚C, 28˚C and 31˚C. The experiment indexes were cell dry weight and extracellular polysaccharide content.

When performing temperature experiment, four gradients of 19˚C, 22˚C, 28˚C, 31˚C were set in single factor experiments to determine the optimum temperature of liquid fermentation of Agaricus blazei, the detection in- dex is the same as the above. Under sterile condition, 5% of inoculum concentration is inoculated to a triangle bottle of 100 ml of liquid fermentation medium, and then cultured at the speed of 150 r/min, the temperature of 19˚C, 22˚C, 28˚C, 31˚C in constant temperature oscillation 3d respectively, measuring its extracellular polysac- charide contents and dry weight of biomass.

3. Analysis of Results

3.1. The Influence of pH on the Liquid Fermentation of Agaricus blazei Murill

Figure 1 which based on the residual sugar contents and extracellular polysaccharide content is used to examine the influence of different pH on the liquid fermentation of Agaricus blazei, while Figure 2 which based on the dry weight biomass per 100 ml bacteria liquid bacteria is taken to identify the effect of different pH on Agaricus blazei. Figure 1 illustrates that the relationship between metabolite accumulations and the growth of Agaricus blazei is similar to positive correlation. When pH ranges from 5.5 to 6.5, dry weight biomass and extracellular polysaccharide contents increased; if pH is more than 6.5, it decreased, Figure 2 shows that Agaricus blazei can grows relatively well between pH 6 and 7 and grows best at pH 6.5, and its extracellular polysaccharide con- tents and dry weight biomass reach 3.85 mg/mL, 1.118 g/100mL respectively.

3.2. The Influence of Rotational Speed on Liquid Fermentation of Agaricus blazei Murrill

Ditto detection index, impact speed of Agaricus liquid fermentation can increase the amount of dissolved oxy- gen in the medium, this provides dissolved oxygen required of Agaricus normal growth and metabolism; on the other hand, speed can provide some centrifugal shear force that will cut down division sites of mycelium fungus

![]()

Figure 1. The effects of different pH on the submerge fermentation of Agaricus blazei Murill.

![]()

Figure 2. The effects of different pH on the submerge fermentation of Agaricus blazei Murill.

ball surface to form smaller ball in order to avoid the formation of excessive bacteria.

From Figure 3, Figure 4 can be seen in 90 - 150 r/min either extracellular polysaccharide content or myce- lium dry weight increases with increasing speed, at the same the amount of residual sugar have a downward trend, but when the speed exceeds 150 r/min showing a downward trend with increasing speed, then the amount of residual sugar begins to rise. To determine the optimum fermentation speed 150 r/min from experiments, ex- tracellular polysaccharide content and cell dry weight, respectively 4.949 mg/mL, 1.078 g/100mL.

3.3. Effects of Inoculation on Liquid Fermentation of Agaricus blazei Murrill

Inoculum is directly related factors of Agaricus liquid fermentation, as the liquid parent species when inoculated using bacteria grow well in the growth stage of fermentation, so when inoculated into the fermentation medium can quickly adapt to the new culture environment, cell have a rapid value-added.

Figure 5 and Figure 6 can be seen that when the inoculum is 4%, whether extracellular polysaccharide or cell

![]()

Figure 3. The effects of different rotational speed on the submerge fermentation of Agaricus blazei Murill.

![]()

Figure 4. The effects of different rotational speed on the submerge fermentation of Agaricus blazei Murill.

![]()

Figure 5. The effects of different inoculation amount on the submerge fermentation of Agaricus blazei Murill.

dry weight values is minimal, this may be due to the small base of the inoculated cells, the reason of the slow appreciation of the cell number. When the amount of inoculum is 8%, 10% and 12%, extracellular polysaccha- ride content and dry cell weight has increased to some extent compared with 4% inoculum, but smaller than when inoculum is 6%, this is probably because when the inoculum amount exceeds 6%, the cell base is large, cell values rapidly, this speeds up the consumption of nutrient medium and medium oxygen consumption, suffi- cient to provide nutrients and oxygen supply needed for normal growth of bacteria. From the experiments we can determine the amount of 6% is the optimum inoculation inoculum, then extracellular polysaccharide content and cell dry weight, respectively 6.38 mg/mL, 1.114 g/100mL.

3.4. Effect of Temperature on Liquid Fermentation of Agaricus blazei Murrill

The impact of temperature on the value of the cell Agaricus is one important factor, because any biochemical enzymatic reactions are associated with temperature changes. Effect of temperature on the fermentation is mul- tifaceted and complex, mainly in the cell growth and product synthesis, physical properties of the fermentation broth and biosynthetic aspects.

From Figure 7, Figure 8, it can be seen, with the rise in temperature of 25˚C before either dry cell weight or extracellular polysaccharide concentrations are elevated along, but when the temperature is above 25˚C, show- ing a downward trend, may be due to a rise in temperature causing bacterial enzyme activity related to cell growth and metabolism reduce, so easy to make bacteria premature age, showing the results presented in the figure. Through experiments we can infer that 25˚C is the optimum growth temperature of liquid fermentation, then extracellular polysaccharide content and cell dry weight respectively 4.408 mg/mL, 1.136 mg/mL.

3.5. Orthogonal Optimization Test of Agaricus Liquid Fermentation Culture Conditions

Based on the above results of single factor, doing orthogonal test of four factors and three levels about pH, speed, inoculum, temperature of affecting Agaricus liquid fermentation, factor level is as shown in Table 1, each level

![]()

Figure 6. The effects of different inoculation amount on the submerge fermentation of Agaricus blazei Murill.

![]()

Figure 7. The effects of different temperature on the submerge fermentation of Agaricus blazei Murill.

![]()

Figure 8. The effects of different temperature on the submerge fermentation of Agaricus blazei Murill.

of the test would be repeated three times or more.

3.6. Orthogonal Experimental Results with Dry Weight of Biomass as Detection Index

Range R indicates the level of impact factors on the experimental results, the size of range R represents the level of impact factors on the experimental results. From Table 2, according to the range R can be obtained four fac- tors effect on the cell dry weight: Temperature > Rotational speed > Inoculation amount > pH, analysis of va- riance was used to test the various factors that impact on the experiment significantly, we can see from Table 3, temperature and speed have great effect on the Agaricus blazei Murrill fermentation liquor, the inoculation has amount effect on Agaricus blazei Murrill fermentation liquor significantly, however, pH has little influence on the fermentation liquor. According to the size of K value from table, we can draw the preferred combination of culture conditions: A2B2C3D2. This is inconsistent with the highest cell dry weight experiment experimental combination A2B2C3D1, hence the need for verification experiment. By experimental verification fermentation obtained by a combination of A2B2C3D2 cell dry weight 1.32 g/100ml, so A2B2C3D2 is the optimal experimental combination, that: temperature (25˚C), speed (150 r/min), pH (7), inoculation amount (6%) for the optimal ex- periment combined to produce biomass as the goal, the dry cell weight can reach 1.32 g/100mL.

3.7. Orthogonal Experimental Results with Extracellular Polysaccharide as Detection Index

Range R* indicates the level of impact factors on the experimental results, the size of range R* represents the level of impact factors on the experimental results. From Table 2, according to the range R* can be obtained four factors effect on the extracellular polysaccharide: Temperature > Rotational speed > pH > Inoculation amount, analysis of variance was used to test the various factors that impact on the experiment significantly, we can see from Table 4, temperature and speed have great effect on the Agaricus blazei Murrill fermentation liq- uor, the inoculation has amount effect on Agaricus blazei Murrill fermentation liquor significantly, however, pH has little influence on the fermentation liquor. According to the size of K* value from table, we can draw the preferred combination of culture conditions: A2B2C2D3. This is inconsistent with the highest extracellular poly- saccharide experiment experimental combination A2B2C2D3, hence the need for verification experiment. By ex- perimental verification fermentation obtained by a combination of A2B2C2D3 cell dry weight 6.95 mg/mL, so A2B2C2D3 is the optimal experimental combination, that: temperature (25˚C), speed (150 r/min), pH (6.5), in- oculation amount (8%) for the optimal experiment combined to produce biomass as the goal, the dry cell weight can reach 6.95 mg/mL.

![]()

Table 2. Orthogonal test results and range analysis.

![]()

Table 3. Orthogonal test results and range analysis.

Note: F0.05(2,2) = 19.0; F0.01(2,2) = 99.0; **: very significant; *: significant.

![]()

Table 4. Variance analysis of orthogonal.

F0.05(2,2) = 19.0; F0.01(2,2) = 99.0; **: very significant; *: significant.

4. Analysis and Discussion

The results show that temperature and rotational speed had a significant impact of extra cellular polysaccharides and Agaricus blazei Murill mycelium, it may be due to effects of bacteria in the fermentation process of intra- cellular enzyme activity and dissolved oxygen in fermentation of sake were temperature and speed, so these two factors were closely related to bacterial metabolism and growth. The other factors of affecting the fermentation have different effects on different fermentation process. Therefore we need to choose the optimal culture conditions in practical applications.

5. Conclusion

Through the research of bacterial liquid fermentation conditions of Agaricus blazei Murill, the results showed that different culture conditions on mycelium growth and extra cellular polysaccharide of Agaricus blazei Murill had a significant impact. When the culture conditions were temperature (25˚C), speed (150 r/min), pH (7) and vaccination (6%) maximum cell content, the mycelium dry weight was 1.32 g/100mL. When the training condi- tions were temperature (25˚C), rotational speed (150 r/min), pH (6.5) and vaccination (8%), the extra cellular polysaccharide content achieved maximum, and the extra cellular polysaccharide content reaches 6.95 mg/mL.

Drawings

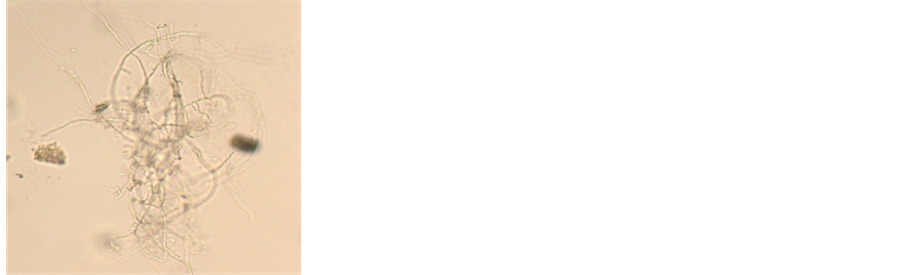

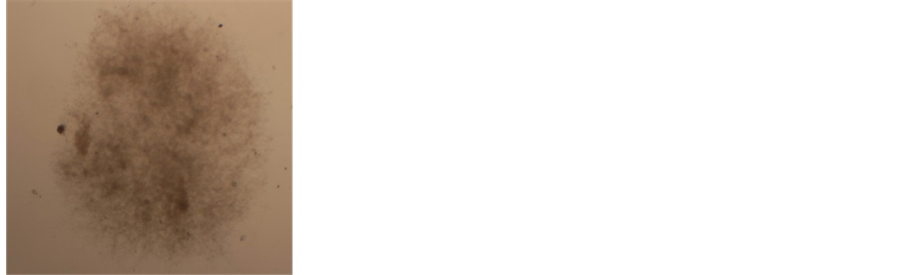

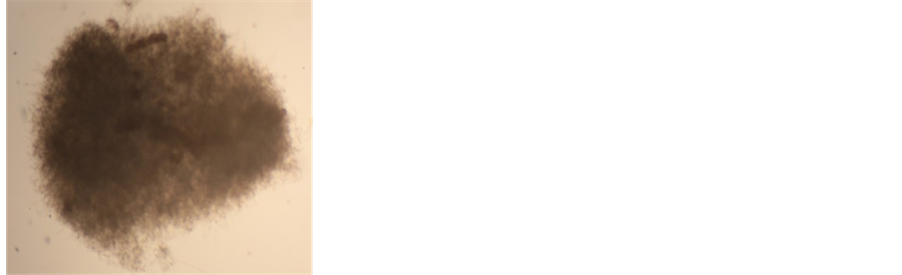

(a) (b) (c)

![]()

![]()

(d) (e) (f)

No 1. Morphology changes at different stage of Agaricus blazei Murill.

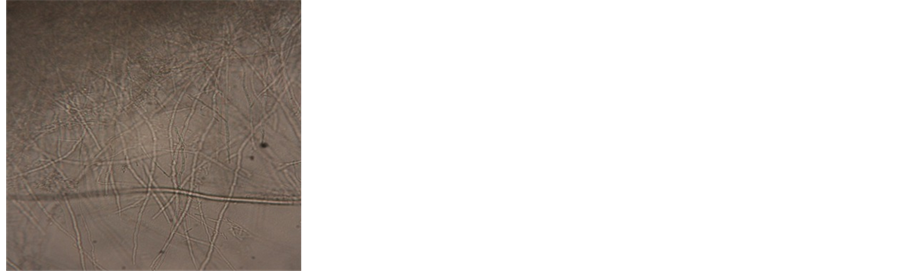

![]() /

/ ![]()

![]()

No 2. Sporocarp tests on liquid spawn of Agaricus blazei Murill.

NOTES

*Corresponding author.