A Preliminary Study of Three Finishing Materials for Traditional Chinese Furniture ()

1. Research Objectives

The present paper is a part of a PhD research project referring to a comparative study of ageing phenomena of wooden support and transparent traditional finishes for European and Chinese furniture.

The current paper covers some preliminary steps within this project, namely:

- A brief presentation of three important Chinese traditional finishing materials as origin and basic properties based on literature data;

- Their experimental macroscopic, microscopic and FTIR investigation.

The resulted data will be used as reference for the further ageing tests to be carried on.

2. Materials and Methods

The three finishing materials selected for this study were purchased from China: Chinese lacquer from East Lake CO., Ltd., Tung oil from Jin Xing Chemical and Chinese wax from Heng Hong Feng La Jiao Ye CO., Ltd.

The macroscopic aspect of the products was observed directly and pictures were taken on samples placed in Petri dishes employing a digital camera (Sony W80).

In order to observe the macroscopic aspect and the microscopic features of resulting dried coating films, the products were applied on microscopic glass lamellas and allowed to dry in normal conditions. Chinese lacquer (viscous liquid) and Tung oil (fluid liquid) were applied (after homogenisation) with a spatula as thin films of about 30 - 50 mm. In the case of Chinese wax (solid product) a small pellet was put on a glass lamella which was placed on a heating plate at 50˚C and allowed to melt and flow freely to form an uniformous thin film and further cooled down at room temperature for re-solidification. The microscopic lamellas were examined under an optical stereomicroscope OPTIKA SZM fitted with an image capture system (OPTIKAM PRO3 video camera), in transmitted light (TL). For the Tung oil a dark field (DF) device was employed in order to increase contrast. From each sample there were taken several images at magnifications of 40× and 80×.

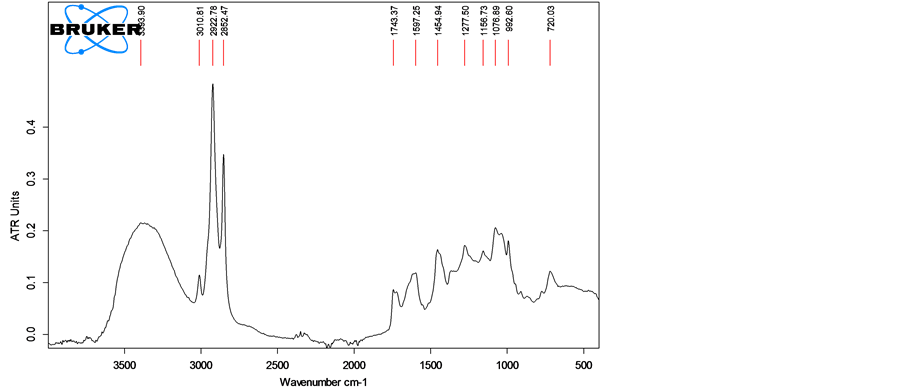

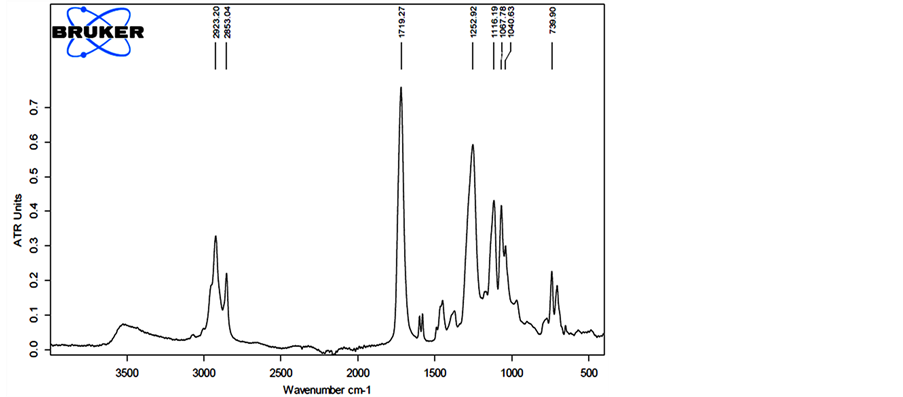

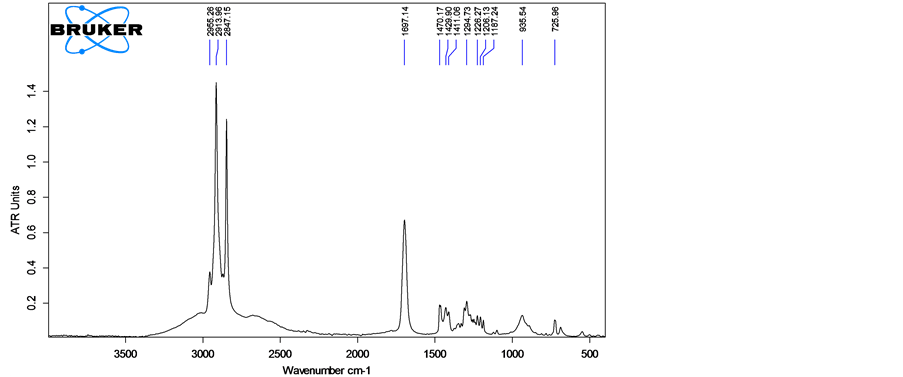

FTIR investigation was performed on the same film samples applied on glass lamellas which were previously observed under microscope. FTIR spectra were recorded employing an ALPHA FT-IR Spectrometer (BRUKER), equipped with ATR (attenuated total reflection) module. The spectra were recorded in the 4000 - 400 cm−1 at a resolution of 2 cm−1, each spectra representing an average of 32 scans.

3. Results and Discussion

The macroscopic aspect of the products can be observed in the pictures included at the bottom of Figure 2. Chinese lacquer is a viscous whitish (milky to cream colour) liquid with sour smell, which colour turns to light brown when exposed to open air. The Tung oil is a homogenous liquid with light yellow colour and characteristic smell. Chinese wax is white solid, with a specific structure, including opaque amorphous material and crystalline, translucent, high reflective, granules.

The dry coating films obtained on glass lamellas could be characterised as follows: dark brown, opalescent, glossy (Chinese lacquer), yellowish, transparent, and glossy (Tung oil), whitish, opalescent, satinated (Chinese wax).

Their microscopic investigation revealed characteristic differentiating features, as can be observed in Figure 3. For the Chinese lacquer film (Figure 3(a) and Figure 3(b)) is characteristic a quite regular microscopic structure with a certain roughness, in which can be observed dark brown insular areas (mostly of around 20 - 40 mm) on a more uniform whitish film with micro-crystalline structure. This is in accordance to studies of Takayuki Honda et al. (2008) [18] and explainable by the complex composition of this material.

A characteristic microstructure, with wavy aspect, could be distinguished also for the Tung oil film when

studied in dark field (Figure 3(c) and Figure 3(d)). Chinese wax forms a high reflective film with a specific less regular pattern (wavy areas alternating with geometrical/rhomboidal areas of 100 - 200 mm), as can be observed in Figure 3(e) and Figure 3(f).

In Figure 4 are presented the FTIR-ATR spectra experimentally recorded for the studied products, while in Tables 1-3 are summarised the main absorbance bands found in these spectra and their assignment in accordance to literature. To facilitate understanding of bands assignment to different functional groups/structural elements, the chemical structure of the main components of these finishing products, as presented in literature, is also included.

The comparative analysis of the spectra and associated tables allows a differentiation of these products based on their characteristic chemical features, which include both common and specific structural elements. For instance, the phenol type structure of the Chinese lacquer is well revealed by a strong –OH band at around 3400 - 3600 cm−1, while the ester type structure of Tung oil and Chinese wax explain the strong C=O band at around 1700 - 1740 cm−1. All the three products contain in their structure long aliphatic chains, presenting therefore

(a)

(a) (b)

(b) (c)

(c)

Table 1. Bands assignment for the FTIR spectra of Chinese lacquer (experimental vs. literature).

Figure 4. The FTIR-ATR spectra of three finishing materials: (a) Chinese lacquer; (b) Tung oil; (c) Chinese wax.

Table 2. Bands assignment for the FTIR spectra of Tung oil (experimental vs. literature).

strong characteristic CH absorption bands (as a two peaks band) at around 2900 cm−1/2850 cm−1. The recorded spectra and data on characteristic bands are in good accordance to literature.

Table 3. Bands assignment for the FTIR spectra of Chinese wax (experimental vs. literature).

4. Conclusion

Three traditional finishing materials important for Chinese historic furniture: Chinese lacquer, Tung oil and Chinese wax, were comparatively investigated. Optical microscopy revealed characteristic microscopic features of the resulting coating films, while the FTIR spectra highlighted both the common and differentiating chemical structure features. These FTIR spectra will be used as references in a further study on the ageing properties of these finishing materials and finished wooden surfaces. This is important for scientific conservation of valuable historic Chinese furniture or other old wooden artefacts.