Properties and Structural Studies of Multi-Wall Carbon Nanotubes-Phosphate Ester Hybrids ()

1. Introduction

Since their discovery in 1991 [1], single (SW) or multi walled (MW) carbon nanotubes (CNT) have attracted a lot of attention owing to their unique physical, chemical, and mechanical properties [2]. CNT are expected to find applications in several technological contexts [2], e.g., as in field emission displays, supercapacitors, and molecular computers. CNT are primarily employed in material science [3] as well as reinforcing agents dispersed in a continuous matrix polymer [4]. As a matter of fact compared to the resin base, polymers reinforced with very low percentages of nanoparticles (about 2% - 5%) present even dramatic improvements in thermo-mechanical properties, barrier properties and fire resistance. CNT may also surpass traditional fillers and fibers (e.g. glass, mineral fillers, calcium carbonate, graphite, metal oxides, carbon black) in heat resistance, dimensional stability and electrical conductivity. The thermal and electrical conductivities of PVC, one of most widely used plastic material, are remarkable modified for adding of MWCNT amounts [5]. Unfortunately, CNT occur in form of aggregated and parallel bundles, as a result of substantial van der Waals interactions [6], which make them unsatisfactorily dispersible or soluble in most common solvents [7]. This constitutes a crucial drawback in their processing. Thus, a number of different approaches have been explored in order to disperse CNT in both aqueous and organic media. These approaches can be, in principle, divided in two categories, i.e. covalent [7-9] and non covalent [10-17] functionalization of the CNT sidewalls. Covalent functionalization involves the formation of new chemical bonds. A convenient method is to convert the CNT sidewalls to nanotube-bound carboxylic acids by means of oxidative degradation [8,9]. Carboxylic acid functionalized CNT can be subjected, for instance, to further chemical modification by amide or ester formation. Recently, Mikhabela et al. proposed the covalent functionalization of the CNT sidewalls by phosphorylation [18]. The phosphorilated MWCNT, obtained by a 1,3-cycloaddition reaction between diphenyl phosphoryl azide and the double bonds of the MWCNT, showed a greater thermal stability than the pristine material. The incorporation of either the pristine or the phosphorilated MWCNT into PVC polymer matrix enhanced its thermal properties, with the phosporilated MWCNT showing a larger improvement. The covalent functionalization of CNT involves a change of carbon hybridization from sp2 to sp3, sometimes leading to a possible partial loss of conjugation which results in decreased electron-acceptor and/or electron-transport properties. For this reason, sometimes, the non-covalent functionalization is preferable, to the covalent ones. Non-covalent functionalization involves van der Waals and π-π interactions and requires the physical adsorption of suitably structured molecules onto the CNT sidewalls preserving the structural integrity of the nanotube and consequently its intrinsic electronic properties. This may be achieved by polymer wrapping, adsorption of surfactants or small aromatic molecules, or interaction with porphyrins or other biomolecules, such as DNA and peptides. Stoddart et al. described the fabrication of SWCNT/field-effect transistor devices by using hybrid SWCNT/pyrenecyclodextrin materials which can serve as chemical sensors to selectively detect nonfluorescent organic molecules, owing to the molecular recognition abilities of the cyclodextrin torus [14]. In this work we describe, by a non-covalent approach, the preparation of hybrids constituted by MWCNT and long chain phosphate esters bearing at least one or two aryl groups (Figure 1). These additives were chosen in order to profit of the beneficial effects that phosphorilation provides to MWCNT physico-chemical stability [18], without affecting their chemical structure and in order to exploit of the proximity of P-O and P=O bonds, present in additives, on the MWCNT surface, that could also modify their thermal conductivity. The obtained hybrids might be profitably applied as a reinforcing agent for polymeric matrix [3-5]. Recently, in fact, to improve the property of CNT, a new method of functionalization by doping CNT with inorganic atoms has been also developed [19,20]. It is known that phosphorus is a doping element which modifies the structure and properties of CNT. The experimental results showed that P-doping changes the optical transition absorptions and thermal conductivity of CNT [19]. Sun et al. developed the synthesis and characterization of P-N doped MWCNT using a floating catalyst chemical vapor deposition method. They observed that, though small, a contribution to the CNT property came of also by oxidized phosphorus present on their surface. Indeed, during the process, the presence of oxygen, adsorbed on the surface of the substrate [20], oxided the phosphorus in P-O and P=O forms.

2. Experimental

2.1. Materials and Instrumentations

All reagents needed were used as purchased (Aldrich), without further purification. MWCNT were provided by Prof. Mazzocchia of Politecnico di Milano, Italy. Nuclear Magnetic Resonance (NMR) spectra were recorded on a Bruker AC-E Series 300 spectrometer. The UV-vis absorbance spectra were recorded with a Beckmann DU

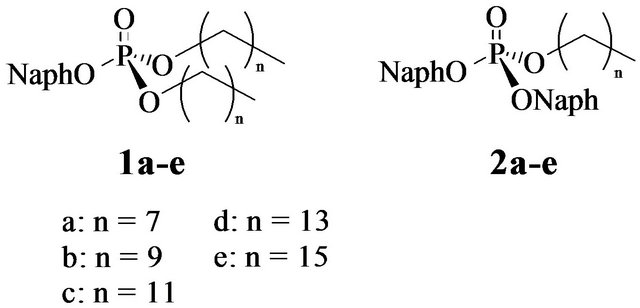

Figure 1. Structures of phosphate ester derivatives.

650 spectrometer. IR spectra were recorded with a PerkinElmer mod. 297 spectrometer.

Fluorescence spectra were acquired with a JASCO FP-777W spectrofluorimeter; the slit widths were fixed at 3 and 5 nm for the excitation and the emission, respectively, the excitation wavelength was fixed at 337 nm and emission interval was fixed at 360 - 450 nm. SEM investigations were performed by using a Philips XL30 equipped with an Energy Dispersive X-ray device. Samples were supported on the stubs by carbon paint. The accelerating voltage ranged between 20 and 25 kV. Thermogravimetric analyses were performed by a Q5000 IR apparatus (TA Instruments) under a nitrogen flow of 25 cm3∙min−1 for the sample and 10 cm3∙min−1 for the balance. The weight of each sample was ca. 10 mg. The measurements were carried out by heating the sample from room temperature to 900˚C at a rate of 10˚C∙min−1.

Micro-Raman spectra were carried out at room temperature by a Bruker-Senterra micro-Raman equipped with a 532 nm diode laser excitation with 20mW power. Measurements were carried out in the range 3500 - 1000 cm−1 with spectral resolution from 9 to 15 cm−1. The dispersions were analysed after removing of the solvent.

2.2. Synthesis of Compounds 1,2 a-e

The proper alkyl alcohol (10 g) was dissolved in Et2O (100 mL), under inert atmosphere (Ar), stirred for a few minutes in an ice bath, and a suitable amount of POCl3 was added. After two days the crude compound was added dropwise, at 0˚C, to a solution of β-naphthol and NaH (molar ratio 1:1) in Et2O (500 mL) under inert atmosphere (Ar). The mixture was stirred for 1 day, and subsequently extracted with water, then with NaOH (0.2 N) and finally with a saturated NaCl solution. The organic phase was dried on MgSO4, filtered and evaporated in vacuum. The residue was purified by chromatography on silica gel (eluents: petroleum ether 100%, ethyl acetate 100%).

Compound 1a: red oil, yield 58%; 1H NMR (300 MHz, CDCl3, δ): 7.80 (m, 3H, Ar H), 7.68 (m, 1H, Ar H), 7.42 (m, 3H, Ar H), 4.16 (m, 4H, O-CH2), 1.68 (m, CH2, 4H), 1.27 (m, 20H, CH2), 0.88 (t, J = 6.4 Hz, 6H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 148.87, 134.29, 131.26, 130.16, 128.07, 127.05, 125.79, 120.49, 116.79, 69.10, 32.12, 30.68, 29.53, 25.80, 23.00, 14.56 ppm. IR (oil): ν = 1286 (s, P=O), 1246 (w, P-O-Ar), 1022 (s, P-O-CH2) cm−1. Anal. calcd. for C26H41O4P: C, 69.62; H, 9.21; P, 6.90. Found: C, 69.66; H, 9.19; P, 6.93.

Compound 1b: red oil, yield 78%; 1H NMR (300 MHz, CDCl3, δ): 7.49 (m, 3H, Ar H), 7.44 (m, 1H, Ar H), 7.37 (m, 3H, Ar H), 4.17 (m, 4H, O-CH2), 1.70 (quintet, J = 6.6 Hz, 4H, CH2), 1.31 (m, 28H, CH2), 0.88 (t, J = 6.6 Hz, 6H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 146.99, 132.41, 129.39, 128.30, 126.20, 125.19, 123.93, 118.62, 114.93, 67.25, 30.40, 28.82, 28.02, 27.82, 27.63, 23.94, 21.20, 12.64 ppm. IR (oil): ν = 1288 (s, P=O), 1245 (s, O-Ar), 1020 (s, P-O-CH2) cm−1. Anal calcd. for C30H49O4P:C, 71.40; H, 9.79; P, 6.14. Found: C, 71.45; H, 9.81; P, 6.12.

Compound 1c: red oil, yield 74%; 1H NMR (300 MHz, CDCl3, δ): 7.81 (m, 3H, Ar H), 7.69 (m, 1H, Ar H), 7.38 (m, 3H, Ar H), 4.18 (m, 4H, O-CH2), 1.70 (quintet, J = 6.7 Hz, 4H, CH2), 1.25 (m, 36H, CH2), 0.89 (t, J = 6.4 Hz, 6H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 151.18, 139.09, 133.86, 129.71, 127.63, 127.46, 126.61, 125.36, 120.06, 116.30, 68.68, 31.87, 30.26, 29.58, 29.30, 29.06, 25.37, 22.64, 14.06 ppm. IR (oil): ν = 1287 (s, P=O), 1246 (s, P-O-Ar) 1052 (s, P-O-CH2) cm−1. Anal. calcd.for C34H57O4P:C, 72.82; H, 10.24; P, 5.42. Found: C, 72.79; H, 10.27; P, 5.41.

Compound 1d: red oil, yield 71%; 1H NMR (300 MHz, CDCl3, δ): 7.81 (m, 3H, Ar H), 7.69 (m, 1H, Ar H), 7.42 (m, 3 H, Ar H), 4.18 (m, 4H, O-CH2), 1.65 (quintet, J = 6.8 Hz, 4H, CH2), 1.29 (m, 44H, CH2), 0.80 (t, J = 6.4 Hz, 6H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 152.30, 130.85, 129.75, 127.67, 127.50, 126.65, 125.40, 120.02, 116.41, 68.71, 31.91, 30.29, 30.19, 29.64, 29.53, 29.34, 29.09, 25.40, 22.66, 14.09 ppm. IR (oil): ν = 1281 (s, P=O), 1246 (s, P-O-Ar), 1019 (s, P-O-CH2) cm−1. Anal. calcd. for C38H65O4P: C, 73.98; H, 10.62; P, 5.02. Found: C, 73.95; H, 10.65; P, 5.00.

Compound 1e: red oil, yield 94%; 1H NMR (300 MHz, CDCl3, δ): 7.81 (m, 3H, ArH), 7.69 (m, 1H, ArH), 7.45 (m, 3H, ArH), 4.16 (m, 4H, O-CH2), 1.70 (m, 4H, CH2), 1.27 (m, 52H, CH2), 0.89 (t, J = 5.41 Hz, 6H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 150.85, 130.86, 129.70, 127.62, 127.45, 126.60, 125.34, 119.97, 116.29, 68.66, 31.86, 30.25, 29.62, 29.50, 29.30, 29.05, 25.36, 22.63, 14.04 ppm. IR (oil): ν = 1280 (w, P=O), 1247 (s, P-O-Ar), 1016 (s, P-O-CH2) cm−1. Anal. calcd. for C42H73O4P:C, 74.96; H, 10.93; P, 4.60. Found: C, 74.99; H, 10.91; P, 4.62.

Compound 2a: red oil, yield 50%; 1H NMR (300 MHz, CDCl3, δ): 7.80 (m, 8H, Ar H), 7.42 (m, 6H, Ar H), 4.32 (m, 2H, O-CH2), 1.72 (quintet, J = 6.9 Hz, 2H, CH2), 1.29 (m, 10H, CH2), 0.86 (t, J = 7.2 Hz, 3H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 148.25, 133.82, 131.02, 129.91, 127.68, 127.54, 126.75, 125.59, 119.97, 116.68, 69.72, 31.64, 30.23, 29.05, 25.32, 22.55, 14.14 ppm. IR

(oil): ν = 1293 (s, P=O), 1241 (s, P-O-Ar), 1039 (s, P-O-CH2) cm−1. Anal. calcd. for C28H31O4P: C, 72.71; H, 6.76; P, 6.70. Found: C, 72.68; H, 6.78; P, 6.72.

Compound 2b: red oil, yield 73%; 1H NMR (300 MHz, CDCl3, δ): 7.82 (m, 8H, Ar H), 7.46 (m, 6H, Ar H), 4.35 (m, 2H, O-CH2), 1.74 (quintet, J = 6.9 Hz, 2H, CH2), 1.25 (m, 14H, CH2), 0.90 (t, J = 6.4 Hz, 3H, CH3); 13C NMR (300 MHz, CDCl3, δ): 148.23, 133.79, 130.99, 129.87, 127.64, 126.71, 125.54, 119.95, 116.64, 69.67, 31.78, 30.20, 29.37, 29.19, 28.96, 25.97, 22.60, 14.03; IR (oil): ν = 1293 (s, P=O), 1241 (s, P-O-Ar), 1020 (s, P-O-CH2) cm−1. Anal. calcd. for C30H35O4P. C, 73.45; H, 7.19; P, 6.31. Found: C, 73.42; H, 7.22; P, 6.33.

Compound 2c: red oil, yield 43%; 1H NMR (300 MHz, CDCl3, δ): 7.80 (m, 8H, Ar H), 7.46 (m, 6H, Ar H), 4.34 (m, 2H, O-CH2), 1.73 (quintet, J = 6.9 Hz, 2H, CH2), 1.26 (m, 18H, CH2), 0.90 (t, J = 5.3 Hz, 3H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 148.21, 133.78, 130.98, 129.87, 127.64, 126.70, 126.20, 125.55, 119.93, 116.64, 69.68, 31.83, 30.19, 29.53, 29.42, 29.36, 29.26, 28.96, 25.29, 22.60, 14.03 ppm. IR (oil): ν = 1293 (s, P=O), 1241(s, P-O-Ar), 1020 (s, P-O-CH2) cm−1. Anal. calcd. for C32H39O4P:C, 74.11; H, 7.58; P, 5.97. Found: C, 74.14; H, 7.62; P, 5.95.

Compound 2d: red oil, yield 55%; 1H NMR (300 MHz, CDCl3, δ): 7.80 (m, 8H, Ar H), 7.45 (m, 6H, Ar H), 4.33 (m, 2H, O-CH2), 1.73 (quintet, J = 6.8 Hz, 2H, CH2), 1.26 (m, 22H, CH2), 0.89 (t, J = 5.9 Hz, 3H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 148.20, 133.77, 130.98, 129.87, 129.36, 127.64, 126.70, 125.55, 119.92, 116.64, 69.69, 31.84, 30.19, 29.57, 29.42, 29.28, 28.96, 25.28, 22.61, 14.10 ppm. IR (oil): ν = 1280 (s, P=O), 1243 (s, P-O-Ar), 1036 (s, P-O-CH2) cm−1. Anal. calcd. for C34H43O4P: C, 74.70; H, 7.93; P, 5.67. Found: C, 74.73; H, 7.91; P, 5.68.

Compound 2e: red oil, yield 48%; 1H NMR (300 MHz, CDCl3), δ): 7.42 (m, 8H, Ar H), 7.30 (m, 6H, Ar H), 4.32 (m, 2H, O-CH2), 1.71 (quintet, J = 7.2 Hz, 2H, CH2), 1.25 (m, 26H, CH2), 0.87 (t, J = 6.6 Hz, 3H, CH3) ppm. 13C NMR (300 MHz, CDCl3, δ): 145.73, 131.31, 128.52, 127.42, 125.19, 124.26, 123.11, 117.48, 114.18, 67.24, 29.39, 28.39, 27.73, 27.16, 26.98, 26.83, 26.51, 22.83, 20.16, 11.59 ppm. IR (oil): ν = 1299 (w, P=O), 1243 (w, P-O-Ar), 1020 (s, P-O-CH2) cm−1. Anal. calcd. for C36H47O4P: C, 75.23; H, 8.24; P, 5.39. Found: C, 75.20; H, 8.27; P, 5.41.

2.3. Formation of the Hybrids

Varying weighted amounts of MWCNT (between 1 × 10−4 and 8 × 10−4 g) were dispersed, for 30 minutes, by sonication in ca. 20 mL of CHCl3 at an ultrasound power of 200 W and a temperature of 25˚C. A CHCl3 solution (100 μL) of phosphate ester additive (0.1 M) was added to the MWCNT dispersions and the resulting systems were again sonicated for further 30 minutes under the same condition previously reported. The final volume of the obtained dispersions was 100 mL and the concentration of additive was 1 × 10−4 M.

3. Results and Discussion

3.1. Formation and Stability of the Hybrids

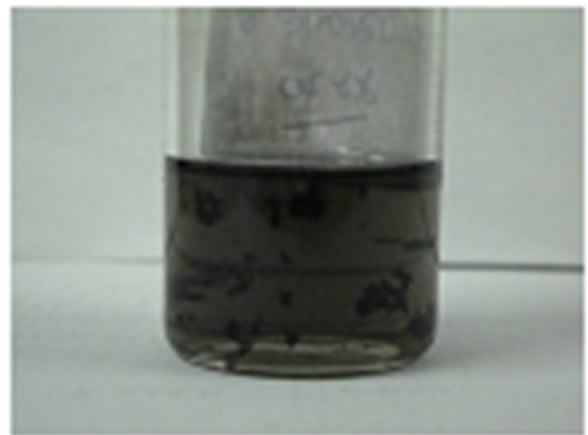

The synthesis of phosphate esters, involved in the formation of hybrids was carried out in the first by reaction between the alcohols, with chain length variable, and a suitable amount of POCl3 and then crude compounds were reacted with the aromatic β-naphthol to obtained the compounds 1,2 a-e (Figure 2). Phosphate esters obtained were used in the formation of hybrids in a concentration range lower than that of micellization [21]. The formation of hybrids was carried out by adding 1 × 10−4 M of phosphate ester to a “dispersion”, at increasing amount, of pristine MWCNTs in CHCl3. Successful functionalization was immediately visible, resulting in the formation of dark dispersions, where the change of color intensity provides a qualitative indication of the amount of nanotube present (Figure 3(a)). By contrast, MWCNTs precipitated out almost completely, after the same sonication protocol, when the phosphate ester was not added (Figure 3(b)). Considering that the stability of a dispersion is the result of a delicate balance of attractive and repulsive forces, it seemed that the improved MWCNT dispersibility is due to the interaction between aryl groups and the CNT surface, [12] because chain phosphate esters, which do not include any conjugated

Figure 2. Scheme of synthesis of phosphate ester derivatives 1,2 a-e.

(a)

(a) (b)

(b)

Figure 3. (a) Dispersions of MWCNT (from 0 to 8 × 10−6 g/mL) obtained after sonication protocol with of phosphate ester 1c (1 × 10−4 M) in CHCl3; (b) Dispersion of pristine MWCNT in CHCl3.

structure, were weakly adsorbed on the CNT surfaces and gave rise to a slight increase in the CNT dispersibility in chloroform. The dispersions were stable from one (2a-e) to at least three (1a-e) weeks. Dispersion stability was assessed by UV-vis analysis. Different dispersions, at varying amounts of MWCNTs (3 × 10−6, 5 × 10−6 and 8 × 10−6 g/mL respectively) and fixed concentration of 1 (1 × 10−4 M) were monitored for three weeks. The change in absorbance, at 272 nm (see below) as a function of time was observed. Indeed, the values of absorbance of MWCNTs pristine and phosphate esters 1a-e were 0.12 and ca. 0.5, respectively, in contrast all hybrids showed absorbance values higher than 1.1 at time 0; this denotes that there was an interaction between phosphate esters and MWCNTs and so the hybrids formation. In Figure 4(a) is shown the plot of the absorbance as a function of time for dispersion with a MWCNT concentration of 5 × 10−6 g/mL. In this case we observed a curve that reach a plateau after ca. three weeks and the ab- sorbance values recorded were ca. 1.3. After three weeks, a slight precipitation of MWCNTs was, also, observed. The same considerations can be made for the dispersion with a MWCNT concentration of 3 × 10−6 g/mL. In

(a)

(a) (b)

(b)

Figure 4. Plot of the absorbance as a function of time for dispersion with a MWCNT concentration of (a) 5 × 10−6 g/mL, (b) 8 × 10−6 g/mL in the presence of phosphate ester 1c.

Figure 4(b) is shown the plot of the absorbance as a function of time for the dispersion with MWCNT concentration of 8 × 10−6 g/mL. In this case we observed a different behavior; in fact, the absorbance value (1.42) initially decreases in a linear manner until at a value of ca. 1.3 after 300 hours, successively, a slight precipitation was observed too. Experimental data collected, showed that dispersions of hybrids with phosphate esters 2a-e were less stable. The greater stability of the hybrids dispersions with phosphate esters 1a-e than with phosphate esters 2a-e can be explained admitting that compounds 1a-e, with two alkyl chains, wrap the MWCNT surface more efficiently than the stiff compounds 2a-e, in spit of their higher π surface. Probably, because the absorbance variations are similar for the two ester classes it is possible to deduce that only one aromatic ring interacts with MWCNT surface, so the different stability is determined by alkyl chains length.