Paper Menu >>

Journal Menu >>

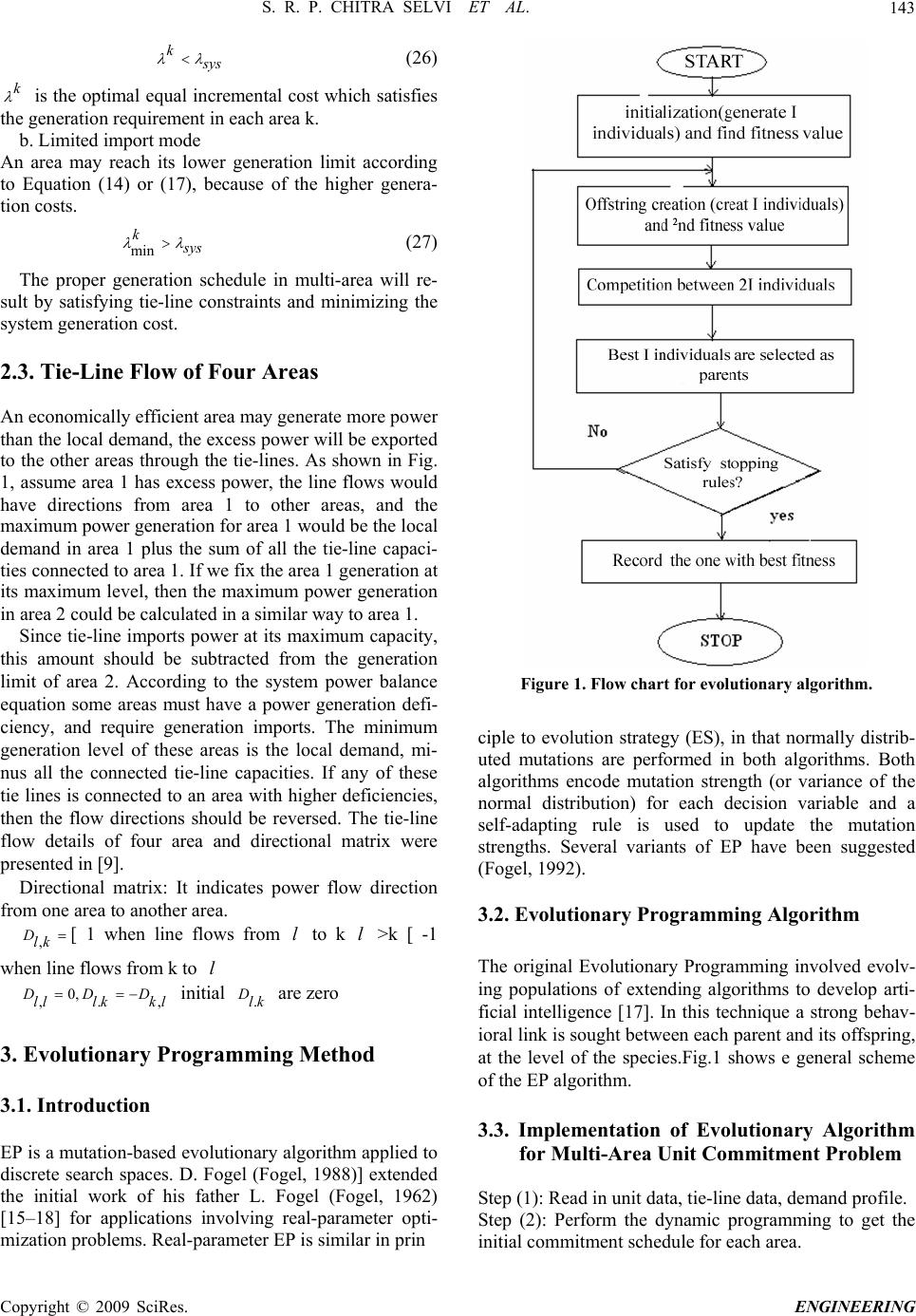

Engineering, 2009, 1, 140-150 doi:10.4236/eng.2009.13017 Published Online November 2009 (http://www.scirp.org/journal/eng). Copyright © 2009 SciRes. ENGINEERING Multi-Area Unit Commitment Using Hybrid Particle Swarm Optimization Technique with Import and Export Constraints S. R. P. CHITRA SELVI1, R. P. KUMUDINI DEVI2, C. CHRISTOBER ASIR RAJAN3 1Department of Electrical Engineering, Anna University, Chennai, India 2Department of Electrical Engineering, Anna University, Chennai, India 3Department of Electrical Engineering, Pondicherry Engg.College, Pondicherry, India E-mail: prakasini2004@yahoo.co.in, kumudinidevi@annauniv.edu, asir_70 @hotmail.com Received January 10, 2009; revised February 21, 2009; accepted February 23, 2009 Abstract This paper presents a novel approach to solve the Multi-Area unit commitment problem using particle swarm optimization technique. The objective of the multi-area unit commitment problem is to determine the optimal or a near optimal commitment strategy for generating the units. And it is located in multiple areas that are interconnected via tie lines and joint operation of generation resources can result in significant operational cost savings. The dynamic programming method is applied to solve Multi-Area Unit Commitment problem and particle swarm optimization technique is embedded for computing the generation assigned to each area and the power allocated to all committed unit. Particle Swarm Optimization technique is developed to derive its Pareto-optimal solutions. The tie-line transfer limits are considered as a set of constraints during the opti- mization process to ensure the system security and reliability. Case study of four areas each containing 26 units connected via tie lines has been taken for analysis. Numerical results are shown comparing the cost so- lutions and computation time obtained by using the Particle Swarm Optimization method is efficient than the conventional Dynamic Programming and Evolutionary Programming Method. Keywords: Multi-Area Unit Commitment, Evolutionary Programming, Dynamic Programming Method, Particle Swarm Optimization Method 1. Introduction In an interconnected system, the objective is to achieve the most economical generation that could satisfy the local demand without violating tie-line capacity con- straints. Due to inter-area transmission constraints, multi- area unit commitment problems (MAUC) are very com- plicated when compared with single-area unit commit- ment problems. Research explores that the application of these existing single-area unit commitment to multi-area unit commitment problem is required [1–4]. Furthermore, unit commitment is treated, as separately from the economic dispatch, the linear fuel cost curve may be an expensive operation schedule or a violation of spinning reserve requirements. In multi-area systems, local generations are not equal to local load demands. Areas with lower fuel cost units may generate more power than their demand and export the excessive energy to the deficient areas; likewise, areas with higher fuel cost units will generate less power than their demand and import the additional energy from other areas with sur- plus capacity. So, the unit commitment of an area should comply with the local generation as well as the local load demand. References [5–11] provide comprehensive study on multi-area scheduling by relating unit commit- ment and economic dispatch with tie-line constraints. The following paragraph discusses some of the method, which is adopted in the multi-area unit commitment problem and their implications. There are some drawbacks in implementing the simple priority list method for unit commitment. Although the technique was fast, the results are far from optimal, es- pecially when there are massive on/off transitions. An- other difficulty is in which did not deal with topological  S. R. P. CHITRA SELVI ET AL.141 k connections in a multi-area system as it considered ex- port/import limitations, which would cause infeasible solutions in many applications. Another approach [6] overcame the previous difficulties. It considered the topological constraints and enhanced unit commitment with economic dispatch .The λ iteration method takes excessive time in finding the optimal solution in large-scale power systems and the speed of the algorithm required some improvement. In the iterative procedure between unit commitment and economic dispatch, there is a need to adjust the unit commitment according to the required area generation. If we use Dynamic Program- ming Sequential Combination (DP-SC) for unit com- mitment in a power pool, the search for an optimal solu- tion is very time consuming. If we adopt the priority list method, there may be a solution gap between the resul- tant schedule and the actual economic operation schedule. If we repeat the process, we may reduce the operation cost, but it will demand a longer execution time. The DP-SC method is used for unit–commitment problem in an interconnected area and particle swarm optimization technique is embedded for assigning generation to each area and modifying the economic dispatch schedule. In this paper, we propose a more efficient approach to the multi-area generation dispatch problem. The pro- posed technique is used to improve the speed and reli- ability of the optimal search process. Instead of using λ iteration method in assigning power generation to each area, we used particle swarm optimization to find the optimal allocation of power generation in each area and entire system. Using particle swarm optimization tech- niques in each area and entire system, we can save time in performing the economic dispatch and operating cost. The meta-heuristic methods [12–19] are iterative tech- niques that can search not only local optimal solutions but also a global optimal solution depending on the problem domain and time limit. In the meta-heuristic methods, the techniques frequently applied to the UC problem are genetic algorithm (GA), tabu search (TS), evolutionary programming (EP), simulated annealing (SA), particle swarm optimization (PSO), etc. They are general-purpose search techniques based on the princi- ples inspired from the genetic and evolution mechanisms observed in natural systems and populations of living beings. These methods have the advantage of searching the solution space more thoroughly. The main difficulty is their sensitivity to the choice of parameters. In this paper, section one introduces that the mathe- matical model of the multi-area unit commitment prob- lem. In the problem formulation, DP method is used for committing the unit in each area and λ iteration method is used for importing and exporting power to other area and minimizes the operating cost. Furthermore, tie-line transfer capacities and area spinning reserve require- ments are also incorporated in order to ensure system security and reliability. The Reserve-sharing scheme is used to enable the area without enough capacity to meet its reserve demand. The objective of MAUC, constraints and conditions of optimal solution are also discussed in this section. Section 3 and 4 explains the EP and PSO algorithm adopted for importing and exporting power to other area. Section 5 gives the results of a case study each one based on a four-area system. A four-area IEEE test power system [6] is then used as an application ex- ample to verify the effectiveness of the proposed method through numerical simulations. A comparative study is also made here to illustrate the different solutions ob- tained based on conventional, EP and PSO methods. Conclusions are presented in the last section. 2. Problem Formulation The cost curve of each thermal unit is in quadratic form 2 () ()() kkk kk F Pga Pgb Pgc iii ii i :$/hr k=1 NA (1) The incremental production cost is therefore 2kkk aPg b ii i (2) or kk P gb i i k ai /2 (3) The start up cost of thermal unit is an exponential function of the time that the unit has been off , () (1 , off X offi j SXA Be iji i ) (4) 2.1. Multi-Area Unit Commitment The objective function for the multi-area unit commit- ment is to minimize the entire power pool generation cost as follows: min[()(1) () ,,, ,1 ,1 ,11 1 N Ntk Aoff kk k IFPgII SX ij jijiji ij ij IP ji k (5) and the following constraints are to be met for optimiza- tion 1) System power balance constraints ; 1....... kk PgDW jt jjj kk (6) where = k Pg j k , k Pgij k 2) Spinning reserve constraints in each area kkkk PgD R EL ijjj i k j ;j=1…t (7) 3) Generation limits of each unit , kk Pg PgPg ij j j k ;i=1…Nk;j=1…t;k=1…NA (8) Copyright © 2009 SciRes. ENGINEERING  S. R. P. CHITRA SELVI ET AL. Copyright © 2009 SciRes. ENGINEERING 142 )0 j )0 j ) , max max 4) Minimum Up and Down time constraints ()*( , ,1 ,1 off on XTII ii ij ij (9) ()*( , ,1 ,1 off off XTII ii ij ij (10) To decompose the problem in Equation (5), it is re- written as min[ ()] , 1 tFPg ij Pj (11) where () ( , 1 Nkkk FPgF Pg ij ij k (12) subject to the constraints of Equation (6) and (8) and following constraints. 5) Export/Import constraints . kkk PgD E ijj j i (13) , kkk PgD L ijjj ik (14) 0 kk ELW jjj ik (15) 6) Area generation limits , kkk k Pg Pg R iji j ii ;=1… N A ; (16) 1...jt , kk P gPg k ij i ii ;=1 N A ;1...jt (17) Each for is represented in the form of schedule tables, which is the solution of the mixed variables optimisation problem ( , kk FPg ij )1...,kN A min[()(1) () ,,, , ,1 , off kk k IFPgII SX ij iijijiij ij IPi (18) Subject to constraints of Equation (7), (9-10) and ini- tial on/off condition of each unit. The multi-area unit commitment problem is solved by Dynamic Programming Sequential Combination (DP-SC) method to form the optimal generation scheduling ap- proach. Among the available generating units in the in- terconnected multi-area system and the proposed method sequentially identifies, via a procedure that resembles bidding, the most advantageous units to commit until the multi-area system obligations are fulfilled and this method has been explained [13]. 2.2. Multi-Area Economic Dispatch The objective of Multi-area Economic Dispatch (MAED) is to determine the allocation of generation of each unit in the system and power exchange between areas so as to minimize the total production cost. The lamda–iteration method is implemented in the MAED to include area import and export constraints and tie-line constraints [15] The objective is to select s ys every hour to minimize the operation cost. kkk PgD E L jjj k j j (19) where , 1 N kk k Pg Pg ji i Since the local demand k j Dis determined in accordance with the economic dispatch within the pool , changes of k g j Pwill cause the spinning reserve constraint of Equa- tion (7) to change accordingly and redefine Equa- tion(18). In this study, the iterative equal incremental cost method ( method) was used to solve Equation (11) and serve as a coordinator between unit commitments in various areas. With the iteration, the system would operate at an optimal point if for each unit is equal to a system incremental cost s ys .Units may operate in one of the following modes when commitment schedule and unit generation limits are encountered: 1) Coordinate mode: The output of unit i is determined by the system incremental cost max, min, sys i i (20) 2) Minimum mode: Unit i generation is at its mini- mum level. min, s ys i (21) 3) Maximum mode: Unit i generation is at its maxi- mum level. max, s ys i (22) 4) Shut down mode: Unit i is not in operation, P gi= 0. Besides limitations on individual unit generations, in a multi-area system, the tie-line constraints in Equation (9), (10) and (14) are to be preserved. The operation of each area could be generalized into one of three modes as follows: Area coordinate mode k s ys (23) max max , kkkk k DLP DE jijj i (24) or max max , kkk LPgDE ijj i k (25) a. Limited export mode When the generating cost in one area is lower than the cost in the remaining areas of the system, that area may generate its upper limit according to Equation (13) or (16), therefore,  S. R. P. CHITRA SELVI ET AL.143 k s ys (26) k is the optimal equal incremental cost which satisfies the generation requirement in each area k. b. Limited import mode An area may reach its lower generation limit according to Equation (14) or (17), because of the higher genera- tion costs. min k s ys (27) The proper generation schedule in multi-area will re- sult by satisfying tie-line constraints and minimizing the system generation cost. 2.3. Tie-Line Flow of Four Areas An economically efficient area may generate more power than the local demand, the excess power will be exported to the other areas through the tie-lines. As shown in Fig. 1, assume area 1 has excess power, the line flows would have directions from area 1 to other areas, and the maximum power generation for area 1 would be the local demand in area 1 plus the sum of all the tie-line capaci- ties connected to area 1. If we fix the area 1 generation at its maximum level, then the maximum power generation in area 2 could be calculated in a similar way to area 1. Since tie-line imports power at its maximum capacity, this amount should be subtracted from the generation limit of area 2. According to the system power balance equation some areas must have a power generation defi- ciency, and require generation imports. The minimum generation level of these areas is the local demand, mi- nus all the connected tie-line capacities. If any of these tie lines is connected to an area with higher deficiencies, then the flow directions should be reversed. The tie-line flow details of four area and directional matrix were presented in [9]. Directional matrix: It indicates power flow direction from one area to another area. , Dlk [ 1 when line flows from to k l >k [ -1 when line flows from k to l l 0, ,. DDD lllkkl , initial are zero . Dlk 3. Evolutionary Programming Method 3.1. Introduction EP is a mutation-based evolutionary algorithm applied to discrete search spaces. D. Fogel (Fogel, 1988)] extended the initial work of his father L. Fogel (Fogel, 1962) [15–18] for applications involving real-parameter opti- mization problems. Real-parameter EP is similar in prin Figure 1. Flow chart for evolutionary algorithm. ciple to evolution strategy (ES), in that normally distrib- uted mutations are performed in both algorithms. Both algorithms encode mutation strength (or variance of the normal distribution) for each decision variable and a self-adapting rule is used to update the mutation strengths. Several variants of EP have been suggested (Fogel, 1992). 3.2. Evolutionary Programming Algorithm The original Evolutionary Programming involved evolv- ing populations of extending algorithms to develop arti- ficial intelligence [17]. In this technique a strong behav- ioral link is sought between each parent and its offspring, at the level of the species.Fig.1 shows e general scheme of the EP algorithm. 3.3. Implementation of Evolutionary Algorithm for Multi-Area Unit Commitment Problem Step (1): Read in unit data, tie-line data, demand profile. Step (2): Perform the dynamic programming to get the initial commitment schedule for each area. Copyright © 2009 SciRes. ENGINEERING  S. R. P. CHITRA SELVI ET AL. Copyright © 2009 SciRes. ENGINEERING 144 Step (3): Initialization of parent population. The initial parent population of size Np is randomly generated for committed unit in each area: 1) To generate the initial parent population (.......)];1,2, 3, 4 &1,2... 1; kp kp Ippkp N p p gN g (28) 2) To calculate the fuel cost for each population using Equation (1) 2 [(()());1,2,3,4&1,2... 11 kp kp K F CaPg bPgckp N p p (29) 3) To calculate the start up cost for each population using Equation (4) 4) To calculate the production cost Production cost= kk F CSC p p (30) 5) To calculate the fitness function for each parent of population ( 1 Nk kp ) K K FFCSC KPGD i PPPi k j (31) The values of the penalty factor is chosen such that if there are any constraints violations then the fitness func- tion value corresponding to that parent will be ineffec- tive. Step (4): Mutation 1) To generate an offspring population Io of size from Np from each parent Ip [(........);1,2, 3, 4;01..... 1 ko ko I PgPg kN p N O in i (32) generated as 2 (0,);1, 2...... KOKOK PgPgNPg iN ii i Similarly all is generated for all areas subjected to Pgi ko ko Pg =Pg ; if Pg< Pg i,mini,m ii ko KO Pg=Pg ; if Pg > Pg ,max ,max ii i (33) 2 (0, )N represents a normal random variable with zero mean and standard deviation (/ )( max ,max ,min FF pi ij Pg ij i ) (34) where is scaling factor, F p i i is the value of fitness function corresponding to I and is the maxi- mum fitness function value among parent population max F 2) To compute the fitness value corresponding to each offspring using Equation (31) Step (5): (competition and selection). The 2I individuals compete with each other for selection using Equation (6). A weight value is assigned to each individual as follows: i W 1 I Wt it W se (35) {1,Wi tf(/ )ufff tt i {0,Wotherwi t (36) where t f is the fitness of the ith competitor randomly selected from 2I individuals and u is a uniform random number ranging over [0, 1].While computing the weight for each individual, it is ensured that each individual is selected only once from the combined population. Even though relative fitness values are used during the process of mutation, competition and selection, it leads to slow convergence. This is because the ratio/( ) tt i f ff is always around 0.5 without uniform distribution between 0 and 1.Hence, the following strategy is followed in this paper to assign weights: {1,Wi tf/() 0.5fff tt i (37) {0,Wotherwis te This weight assignment is found to yield proper selec- tion and good convergence. When all the 2I individuals obtain their weights, they are ranked in descending order and the first I individuals are selected as parents along with their fitness values for next generation. Steps (4) and Steps (5) are repeated until there is no appreciable improvement in the minimum fitness value. Step (6): Optimum generation schedule is obtained for four areas using minimum fitness value. Check area gen- eration with local demand Step (7): Areas with lower fuel cost may export the excessive generation to other areas with higher fuel cost (deficiency areas) with tie line limit. 4. Particle Swarm Optimization Particle swarm optimization (PSO) is inspired from the collective behavior exhibited in swarms of social insects [19]. It has turned out to be an effective optimizer in dealing with a broad variety of engineering design prob- lems. In PSO, a swarm is made up of many particles, and each particle represents a potential solution (i.e., indi- vidual). A particle has its own position and flight veloc- ity, which are adjusted during the optimization process based on the following rules: 1() ()() () 12 P PKPKP KP VVCrandP PCrandP P iii gii bi KP (38) 1 K PKPP PPV iii (39) where 1 Vt is the updated particle velocity in the next iteration,V is the particle velocity in the current itera- tion, t is the inertia dampener which indicates the im-  S. R. P. CHITRA SELVI ET AL.145 pact of the particle’s own experience on its next move- ment, represents a uniformly distributed num- ber within the interval [0, c1], which reflects how the neighbours of the particle affects its flight, 1 Crand K P bi P is the neighbourhood best position, P i V is the current position of the particle and represents a uniformly distributed number within the interval [0, c2], which in- dicates how the particle trusts the global best position, 2 C rand K P g i P is the global best position, and is the up- dated position of the particle. Under the guidance of these two updating rules, the particles will be attracted to move towards the best position found thus far. That is, the optimal solutions can be sought out due to this driv- ing force. 1P i V The major steps involved in Particle Swarm Optimiza- tion approach are discussed below: 1) Initialization The initial particles are selected randomly and the ve- locities of each particle are also selected randomly. The size of the swarm will be (Np x n), where Np is the total number of particles in the swarm and ‘n’ is the number of stages. 2) Updating the Velocity The velocity is updated by considering the current ve- locity of the particles, the best fitness function value among the particles in the swarm. The velocity of each particle is modified by using Equation (28) The value of the weighting factor is modified by following Equation (40) to enable quick convergence. ()iter/ mmax i max ax min ter (40) The term < 1 is known as the “inertia weight” and it is a friction factor chosen between 0 and 1 in order to determine to what extent the particle remains along its original course unaffected by the pull of the other two terms. It is very important to prevent oscillations around the optimal value. 3) Updating the Position The position of each particle is updated by adding the updated velocity with current position of the individual in the swarm 4.1. Algorithm of Particle Swarm Optimization The step by step procedure to compute the global optimal solution is followed. Step (1): Initialize a population of particles with ran- dom positions and velocities on d dimensions in the problem space. Step (2): For each particle, evaluate the desired opti- mization fitness function in the variables. Step (3): compare particles fitness evolution with par- ticles . If current value is better then, then set value equal to the current value, and the location equal to the current location in the di- mensional space. Pbest Pbest Pbest stPbe Step (4): Compare fitness evaluation with the popula- tions overall previous. If current value is better than Pbest g best [( , then reset to the current particles array in- dex and value. Step (5): Change the velocity and position of the parti- cle according to Equations (38) and (39) respectively. Step (6): Loop to step 2 until a criterion is met, usually a sufficiently good fitness or a maximum number of it- erations. 4.2. Implementation of Particle Swarm Optimization Algorithm for Multi-Area Unit Commitment The various steps of the PSO algorithm are given below for solving multi area unit commitment problem: Step (1): Read in unit data, tie-line data, load demand profile. Step (2): Perform the dynamic programming to get the initial commitment schedule for each area. Step (3): Initialization of particle .The initial particle of size Np is generated randomly for committed unit in each area : 1) Calculate the initial particle population .....);1,2,3,4:1..... 12 kp kp I PPkp N p p (41) 2) Calculate the fuel cost for each particle using Equa- tion (1) 2 )());1,2, 3,4;1,2... 11 kp kp [( ( k F CaPbPckpN p p (42) 3) Calculate start up cost of each particle using Equa- tion (4) 4) Calculate the production cost Production Cost =k FC pk SC p (43) 5) Calculate the fitness function for each particle of population k FC () p1 Nkkp k FSCkP pp i i k D j (44) 6) To calculate the by using fitness function values, If current value is better then previous,then set value equal to the current value and compute Pbest Pbest Pbest g best 1 if current value is. Step (4): Updating the Velocity The velocity is updated by considering the current velocity of the particles, the best fitness function value among the particles in the swarm using following Equation (45). () ()() () 12 P PKPKP KP CrandP PCrandP P i gii bi KP V V ii (45) Copyright © 2009 SciRes. ENGINEERING  S. R. P. CHITRA SELVI ET AL. Copyright © 2009 SciRes. ENGINEERING 146 where is weight factor, The weight is computed using Equation (40) Step (5): Updating the particle position The position of each particle is updated by adding the updated velocity with current position of the individual in the swarm. 1 K PKPP PPV iii (46) The steps described in sub Sections 3 to 5 are repeated until a criterion is met, usually a sufficiently good fitness the maximum generation count is reached. Step (6): Op- timum generation schedule is obtained for four area us- ing gbest particle. Check area generation with local de- mand. Step (7): Areas with lower fuel cost may export the excessive generation to areas with higher fuel cost (defi- ciency areas) with tie line limit 5. Test System and Simulation Results The proposed MAUC algorithm has been implemented in C++ environment and tested extensively. Test results of a multi-area system are presented in this section. All simulations are performed in a PC with Intel processor (1.953 GHz) and 1012 MB of RAM. As shown in Figure 2, a sample multi-area system with four areas, IEEE reliability test system, 1996 data in [9], are used to test the speed of solving the multi-area UC and ED for a large-scale system with import/export capability and tie line capacity constraints. In the sample multi-area system, each area consists of 26 units. The total number of units tested is 104, and their characteris- tics are presented in [9]. There are some identical ther- mal units also located in each area. The system contains five tie lines four area interconnections as shown in Fig- ure 4, and area one is the reference area. Figure 3 shows the modified same load demand profile forecast used in all four areas. The assumptions described in tie line ca- pacity constraint are applied to the simulations. The four areas have the same load demand profiles. As the 1oad demand is same in these four areas, the eco- nomical area will generate more power than expensive areas. Figure 3 gives the changes in area 1 power genera- tion, committed unit capacities, unit commitment pattern of hour 7am and spinning reserve requirement of area 1 is 400MW, because the available unit capacities are not more than the power generation plus the spinning reserve. This phenomenon proves that the available capacity should comply with the area power generation instead of the local load demand. The systems 1oad demand is 6800 MW, so area 1 generation increases steadily while that of area 2, 3 de- creases. The incremental cost of area 2, 3 is higher than Figure 2. Topological connections of four areas. Figure 3. Load pattern for all four –area. Figure 4.Tie-line flow pattern for 7am. that of the other two areas since the tie flows to area 2, 3 are at their maximum capacities. This manifests that the proposed method considers tie-line limits effectively. Table I shows that parameter used in EP and PSO method. Table 2, 3, 4 and Table V shows comparison result of DP and EP, PSO. Figure 4 and 5 shows the convergence characteristics for multi-area obtained using proposed methodology. Table 2 shows that the total production cost is obta-  S. R. P. CHITRA SELVI ET AL.147 Table 1. Parameter used in EP & PSO. ined by using conventional method. Table 3 and 4 shows that the total production cost is obtained for ten iterations by using EP and PSO method. Figure 4 gives the plot of EP average performance from 500 runs. Figure 5 gives the plot of number of iteration versus the time taken to complete those iterations and the maximum production cost obtained under each iteration using PSO method. As we indicated in the paper, the PSO algorithm has also proved to be an efficient tool for solving the multi –area unit commitment with economic dispatch problem. There is no obvious limitation on the size of the problem that must be addressed, for its data structure is such that the search space is reduced to a minimum; no “relaxation of constraints” is required; instead, populations of feasi- ble solutions are produced at each generation and throu- ghout the evolution process. The main advantages of the proposed algorithm are speed. The proposed PSO approach was compared to the re- lated methods in the references indented to serve this purpose, such as the DP with a zoom feature, and the EP approaches. In addition, with the use of PSO method, the status is improved by avoiding the entrapment in local minima. By means of stochastically searching multiple points at one time and considering trial solutions of suc cessive generations, the PSO approach gives global minima instead of entrapping in local optimum solutions. The PSO method obviously displays a satisfactory per- formance with respect to the quality of its evolved solu- tions and to its computational requirements. The final result of PSO would save 0.12% $2865.4 is compared with the solution obtained by the conventional method but it would require 33 seconds to complete the computation .So, the EP method is reduced the operating cost by 0.08 % than the conventional method but it re- quires 36 seconds to complete this computation .From these results, the PSO method had less total cost and con- sumed also less CPU time compared to other method. 6. Conclusions Application of PSO is a novel approach in solving the MAUC problem. Results demonstrate that PSO is a very competent method to solve the MAUC problem. PSO Table 2. Operating cost of DP method. generates better solutions than the other methods, mainly because of its intrinsic nature of updates of positions and velocities. The reason is due to the hourly basis solu- tion. This is somehow similar to the “divide and con- quer” strategy of solving a problem. Owning to this Parameter EP PSO Population size(p) 10 10 Mutation scaling factor(β) 0.03 - Penalty factor(k1) 10000 1000 0 Maximum Generation 500 500 Learning factor(c1,c2) - 2 Hours (24) Area-1 (26 Unit) Area-2 (26 Unit) Area-3 (26 Unit) Area-4 (26 Unit) 1 37115.330 08 24115.5214 8 28331.2265 6 22042.12 500 2 24747.960 94 23137.6396 5 22994.8997 4 19289.81 836 3 27995.107 42 23137.6396 5 23701.2568 4 19175.97 998 4 29576.867 19 18274.3261 7 26151.8378 9 18397.77 637 5 29347.660 16 18329.3261 7 25595.4296 9 18698.77 344 6 36118.037 11 18329.3261 7 23799.5097 7 19705.58 106 7 40483.162 11 28104.1445 3 21999.5986 3 24891.27 832 8 39248.855 47 32917.4687 5 19852.8554 7 21117.69 727 9 38728.734 38 34865.2382 8 18245.3730 5 21253.34 180 10 37215.339 84 32205.3750 0 22093.5957 0 24255.43 945 11 37193.468 75 32205.3750 0 20244.0820 3 23298.57 031 12 38310.472 66 32205.3750 0 20992.8925 8 21298.69 336 13 33225.353 52 34149.0293 0 18152.8222 7 26442.17 773 14 31623.279 30 37085.8281 3 17146.9394 5 25955.68 945 15 30595.626 95 33172.8613 3 17991.4726 6 23682.43 359 16 36312.250 00 32989.6523 4 22492.5781 3 25305.94 336 17 36925.175 78 32989.6523 4 23769.5800 8 25383.72 656 18 35682.320 31 39459.6250 0 27589.7597 7 19501.75 391 19 35682.320 31 39903.0585 9 23860.8418 0 22304.66 016 20 35682.320 31 32114.9414 1 21973.3906 3 15999.40 332 21 38042.478 52 29387.7168 0 19907.5390 6 20248.24 805 22 30190.896 48 15095.1718 8 21115.4316 4 21807.76 953 23 30923.708 98 18398.0820 3 19966.2128 9 22309.07 813 24 30202.210 94 15198.7812 5 19815.6132 8 18294.49 805 Total cost 821168.93 75 677771.156 3 527784.731 2 520660.4 566 Copyright © 2009 SciRes. ENGINEERING  S. R. P. CHITRA SELVI ET AL. Copyright © 2009 SciRes. ENGINEERING 148 Table 3. Opearting cost of EP method. Table 4. Operating cost of PSO method hourly solution, the complexity of the search is greatly reduced. The total objective function is the sum of objec- tives and constraints, which are fuel cost, start-up cost, Table 4. Operating cost of PSO method. spinning reserve, power demand, tie-line limit, and im- port and export constraints. For a better solution, genera- ted powers by N unit of generators and K areas, tie –line limits are constantly checked so that feasible particles can meet the power demand .This reduces the pressure of Hours (24) Area-1 (26 Unit) Area-2 (26 Unit) Area-3 (26 Unit) Area-4 (26 Unit) 1 37096.33008 24048.52148 28309.226 56 21998.125 00 2 24514.96094 23004.63965 22910.899 74 19251.818 36 3 27980.10742 23004.63965 23674.256 84 19145.979 98 4 29568.86719 18286.32617 26111.837 89 18374.776 37 5 29387.66016 18286.32617 25578.429 69 18671.773 44 6 35838.03711 18286.32617 23769.509 77 19673.581 06 7 40497.16211 28043.14453 21945.598 63 24858.278 32 8 39228.85547 32977.46875 19815.855 47 21081.697 27 9 38648.73438 34802.23828 18245.373 05 21201.341 80 10 37229.33984 32191.37500 22063.595 70 24199.439 45 11 37184.46875 32191.37500 20212.082 03 23272.570 31 12 38294.47266 32191.37500 20979.892 58 21262.693 36 13 33200.3535234120.0293 18127.822 27 26401.177 73 14 31630.27930 37051.82813 17124.939 45 25928.689 45 15 30578.62695 33162.86133 17978.472 66 23631.433 59 16 36281.25000 32960.65234 22459.578 13 25277.943 36 17 36949.17578 32960.65234 23748.580 08 25365.726 56 18 35766.32031 39439.62500 27569.759 77 19465.753 91 19 35766.32031 39811.05859 23839.841 8 22243.660 16 20 35766.32031 32081.94141 21943.390 63 15968.403 32 21 38122.47852 29353.71680 19897.539 06 20208.248 05 22 30177.89648 15065.17188 21073.431 64 21791.769 53 23 31583.70898 18379.08203 19966.212 89 22270.078 13 24 29449.21094 15159.78125 19816.613 28 18211.498 05 Total cost 820740.9375 676860.1562 527162.73 96 519756.45 65 Hour -s (24) Area-1 (26 Unit) Area-2 (26 Unit) Area-3 (26 Unit) Area-4 (26 Unit) 1 37112.330 08 24093.521 48 28311.2265 6 22002.12500 2 24741.960 94 23127.639 65 22964.8997 4 19259.81836 3 27988.107 42 23127.639 65 23681.2568 4 19151.97998 4 29566.867 19 18254.326 17 26121.8378 9 18367.77637 5 29337.660 16 18309.326 17 25572.4296 9 18678.77344 6 36108.037 11 18309.326 17 23789.5097 7 19683.58106 7 40473.162 11 28084.144 53 21975.5986 3 24861.27832 8 39238.855 47 32897.468 75 19822.8554 7 21087.69727 9 38718.734 38 34841.238 28 18215.3730 5 21223.34180 10 37202.339 84 32185.375 00 22063.5957 0 24205.43945 11 37183.468 75 32185.375 00 20224.0820 3 23278.57031 12 38296.472 66 32185.375 00 20972.8925 8 21268.69336 13 33212.353 52 34129.029 30 18132.8222 7 26412.17773 14 31607.279 30 37063.828 13 17126.9394 5 25920.68945 15 30578.626 95 33152.861 33 17981.4726 6 23642.43359 16 36281.250 00 32969.652 34 22462.5781 3 25286.94336 17 36919.175 78 32969.652 34 23749.5800 8 25353.72656 18 35662.320 31 39439.625 00 27569.7597 7 19471.75391 19 35662.320 31 39893.058 59 23839.8418 0 22274.66016 20 35662.320 31 32094.941 41 21943.3906 3 15969.40332 21 38032.478 52 29365.716 8 19887.5390 6 20218.24805 22 30177.896 48 15065.171 88 21073.4316 4 21797.76953 23 30913.708 98 18387.082 03 19946.2128 9 22279.07813 24 30182.210 94 15168.781 25 19796.6132 8 18254.49805 Total cost 820859.93 75 677300.15 62 527225.739 6 519950.4565  S. R. P. CHITRA SELVI ET AL.149 Figure 4. Convergence characteristics of EP method. Figure 5. Convergence characteristics of PSO method. Table 5. Comparison of DP, EP, PSO method. the constraint violation of the total objective function. Finally, the result obtained from the simulation is most encouraging in comparison to the best-known solution so far. In the future work, the power flow in each area can be considered to further increase the system security. Other issues such as transmission losses, transmission costs, call and put options policies between and bilateral contract areas can also be considered to reflect more re- alistic situations in MAUC problems. 7. References [1] S. Salam, “Unit commitment solution methods,” Pro- ceedings of World Academy of Science, Engineering and Technology, Vol. 26, December 2007. [2] B. Lu and M. shahidehpour, “Short term scheduling of combined cycle units,” IEEE Transaction on Power Sys- tem, Vol. 19, pp. 1616–1625, August 2004. [3] F. Gao, “Economic dispatch algorithms for thermal unit system involving combined cycle units,” IEEE and Ge- rald Bushel IEEE Lowa State University Ames, IA, USA, IEEE Transaction on Power Systems, pp. 1066–1072, November 2003. [4] E. Fan, X. H. Guan, and Q. Z. Zhai, “A new method for unit commitment with ramping con straints,” IEEE Transaction on Power Systems, March 2001. [5] H. T. Yang and C. L. Huang, “Evolutionary programming based economic dispatch for units with non-smooth fuel cost functions,” IEEE Transactions on power system, Vol. 11, No. 2, pp. 112–118, 1996. [6] Z. Ouyang and S. M. Shahidehpour, “Heuristic multi-area unit commitment with economic dispatch,” IEEE Pro- ceedings, Vol. 138, No. 3, pp. 242–252, 1991. [7] C. L. Tseng, “Multi-area unit commitment for large scale power system,” IEEE Proceedings - Generation and Dis- tribution, Vol. 145, No. 41, pp. 415–421, 1999. [8] C. Wang and M. Shahidehpour, “A decomposition ap- proach to non-linear multi-area generation scheduling with tie-line constraints using expert systems,” IEEE Transactions on Power System, Vol. 7, No. 4, pp. 1409 –1418, 1992. [9] C. K. Pang, G. B. Sheble, and F. Albuyeh, “Evaluation of dynamic programming based methods and multiple area representation for thermal unit commitments,” IEEE Transactions on Power Apparatus System, Vol. 100, No. 3, pp. 1212–1218, 1981. [10] F. N. Lee, J. Huang, and R. Adapa, “Multi-area unit com- mitment via sequential method and a DC power flow network model,” IEEE Transactions on Power System, Vol. 9, No. 1, pp. 279– 284, 1994. [11] C. Yingvivatanapong, W. J. Lee, and E. Liu, “Multi-area power generation dispatch in competitive markets,” IEEE Transactions on Power Systems, pp. 196–203, 2008. [12] U. B. Fogel, “On the philosophical differences between evolutionary algorithms and genetic algorithms,” IEEE Proceedindings in Second Annual Conference on Evolu- tionary Programming, pp. 23–29, 1993. [13] T. Biick and H. P. Schwefel, “An overview of evolution- ary algorithm for parameter optimization,” Evolutionary Computation, Vol. 1, No. 1, pp. 1–24. 1993. [14] C. C. Asir Rajan and M. R. Mohan, “An evolutionary programming-based tabu search method for solving the unit commitment problem,” IEEE Transactions on Power System, Vol. 19, No. 1, pp. 577–585, 2004. [15] D. Srinivasan, F. Wen, and C. S. Chang, “A survey of applications evolutionary computing to power systems,” IEEE Proceedings, USA, pp. 35–41, 1996. [16] J. Kennedy, “The particle swarm: Social adaptation of knowledge,” Proceedings in International Con- ference on Evolutionary Computation, Indianapolis, pp. 303–308, 1997. Copyright © 2009 SciRes. ENGINEERING  S. R. P. CHITRA SELVI ET AL. Copyright © 2009 SciRes. ENGINEERING 150 Appendix A Nomenclature k Pgi Upper limit of power generation of unit i in area k k Dj Total load demand in area k at jth hour , k Pgij Power generation of unit i in area k at j th hour k Lj Total import power to area k at jth hour k Ej Total export power to area k at jth hour k Rj Spinning reserve of area k at j th hour , k I ij Commitment state (1 on, 0 for off) k j S Total commitment capacity for area k at j th hour Irlist List of committed units ascending pri- ority order k SD j Total system demand at j th hour Total time span in hours t i Index for units j Index for time on Ti Minimum up time of unit i i Lagrangian multiplier for unit s ys Lagrangian multiplier for entire system off Ti Minimum down time of unit i N A Total number of areas i Time constant in start up cost function for unit i Nk Total number of units in area K Oplist List of uncommitted units in descend- ing order Wj Net power exchange with outside systems k Pg j Power generation of area k at jth hour k Pgi Lower limit of power generation of unit i in area k / , on off Xij Time duration for which unit i has been on/off at jth hour |