Energy and Power Engineering

Vol. 5 No. 2A (2013) , Article ID: 30668 , 9 pages DOI:10.4236/epe.2013.52A006

Harvest of Short-Rotation Woody Crops in Plantations with a Biobaler

1Agriculture and Agri-Food Canada, Soils and Crops Research and Development Centre, Québec, Canada

2Département des Sols et de Génie Agroalimentaire, Université Laval, Québec, Canada

3Canadian Forest Services, Canadian Wood Fibre Centre, Natural Resources Canada, Edmonton, Canada

Email: philippe.savoie@fsaa.ulaval.ca, pierre-luc.hebert.1@ulaval.ca, francois-simon.robert.1@ulaval.ca, Derek.Sidders@NRCan-RNCan.gc.ca

Copyright © 2013 Philippe Savoie et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received February 27, 2013; revised March 26, 2013; accepted April 13, 2013

Keywords: Biomass; Harvesting; Willow; Woody Crop; Feedstock

ABSTRACT

The biobaler is an alternative to the modified self-propelled forage harvester to cut and collect short rotation woody crops (SRWC). It is less capital intensive and more versatile, being able to harvest woody crops on plantations, on abandoned farmland, on brush land or within forest understory. The biobaler was evaluated specifically on five different plantations over 19 experimental units (546 bales harvested with an average mass of 427 kg and 49% moisture content). Average bale density was 266 kg wet mass (WM)/m3 or 139 kg dry mass (DM)/m3. Average harvest capacity was 35 bales/h (7.7 t dry matter/h), and ranged from 23 to 48 bales/h. Harvest in plantations with a 149 kW tractor cost on average CAN $175/h, $5/bale and $22.84/t DM. Non recovered biomass (field loss) averaged 11% at random locations in the field and 8% at the point of bale ejection as a result of chip abrasion. While the biobaler remains a versatile harvester for SRWC, its preferred utilization will be in environments of diverse woody crops with final application as a rough mulch or for combustion in furnaces requiring minimal processing or size reduction.

1. Introduction

Short rotation woody crops (SRWC), also known as short rotation coppice (SRC), are densely planted, high-yielding varieties of willow or poplar [1]. One year after planting, stems are usually cut back to encourage growth of multiple stems. The biomass is then harvested typically once every two to four years for a life cycle usually greater than 20 years.

The development of energy crops on farm land and in the forest zone depends on several factors such as land availability, expected markets, price of energy, alternate crops, cost of production, land owner expectations, policy and subsidies [2]. The growth of short rotation poplar has been suggested on riparian land (beach shore) in China to provide environmental improvement and a potentially important new source of biomass [3]. Willow plantations can also be established on underused low-tomedium quality agricultural land but harvest costs can be quite high, ranging between 39% and 60% of production cost [4].

An Italian study indicated harvest costs of 15 EUR/green t when harvesting poplar SRC with a modified self-propelled forage harvester (SPFH) equipped with a specially-designed saw blade cutter-header [5]. These harvesters work well over large plantation areas in an industrial setting, with typical investment per unit between 340,000 and 440,000 EUR, depending on engine power in the range of 254 to 445 kW [5]. However, many future plantations are considered on small or segmented areas of marginal land, where smaller and relatively robust equipment would be preferable.

A novel harvester, called the biobaler, was developed to harvest woody biomass either in plantations or in natural stands in the form of round bales [6]. The biobaler represents a lower capital investment ($150,000 or about 115,000 EUR) compared to the modified SPFH but it also requires an independent tractor. Although the original biobaler was also designed with a saw blade cutter [7], it has been commercialized with a more robust flail cutter [8]. The flail header was shown to be suitable to collect forest underbrush in Florida natural forest [9], to remove invasive brush in Saskatchewan prairie [10] and to harvest other native small woody crops in central Canada and Minnesota brushland [11].

Meanwhile, only limited data have been published on the biobaler’s ability to harvest woody crops in plantations. The original experimental prototype with a flail cutter was used to harvest a limited quantity of willow from a plantation (52 bales) at an average rate of 11 t wet matter (WH)/h or 27 bales/h [6]. The commercial machine, known as the biobaler WB-55, is considerably more robust than the prototype. New machinery management data will be useful to assess capacity, operational requirements and limitations in cultivated SRWC. The objective of this study was to measure harvest capacity, fuel consumption and field losses in a wide range of SRWC plantations, and to estimate harvest cost in this context.

2. Materials and Methods

2.1. Description of Functional Principles of the Biobaler WB-55

A commercial version of the biobaler, manufactured by the Anderson Group [8] as model WB-55, was utilized for harvest. The main mechanisms of the biobaler are illustrated in Figure 1. A flail cutting and mulching roll is located in front of the machine to cut standing stems, partially shred them, move them through a feeding roll and push stems toward the compression chamber. Stems become more flexible as a result of partial shredding. When they reach the compression chamber, they are rolled into a spiral to form a round bale nominally of 1.22 m in diameter by 1.22 m in width. Compression rolls around the chamber perimeter exert pressure as the bale is formed. When the chamber is full, the baler stops in the field, twine is unrolled for attachment and, upon completion of tying, the tail gate opens, the bale is ejected and dropped onto the ground. Bale width and diameter can vary slightly depending on amount of biomass and expansion after ejection from the chamber.

The original prototype cutting system was made of pivoting flail hammers [6]. The commercial model is composed of more aggressive interchangeable fixed cutting hammers (Figure 2). The total cutting roll width is 2.25 m. The machine can cut stems with diameters as large as 150 mm at the point of cut, but its capacity is higher when stems are smaller than 75 mm diameter. Proper operation of the commercial biobaler WB-55 requires a minimum tractor power of 134 kW (PTO 1000 RPM) and four hydraulic outputs. The tractor should be equipped with guards to protect vulnerable mechanical components such as the fuel reservoir, the radiator and hydraulic lines. For all experiments reported here, a Fendt 818 tractor was used to operate the biobaler in the field (Figure 3). The tractor had nominal power of 136 kW; its engine settings were adjusted to obtain a peak power of 149 kW.

2.2. Plantations

The research was conducted on five different SRWC plantations in Québec and Ontario (Canada) between August 2009 and November 2010. The plantations in Québec were single rows spaced 1.8 m apart in groups of six rows, with a larger 3.0 m spacing between groups of six rows. Cuttings were originally planted at a 0.3 m distance along the row (16,667 cuttings/ha). The plantations in Ontario were triple rows spaced 0.6 m apart, with a 2.0 m spacing between groups of three rows. Cuttings were originally planted at 0.6 m distance along the row (15,625 cuttings/ha).

Over time, each cutting becomes a stump with multiple stems. Just prior to harvest, plantations were characterized by stem density and stem diameter at breast height (DBH, i.e. 1.35 m above the ground). This was done by counting systematically all stems over random 5-m lengths and measuring stem DBH with a caliper (+/− 0.1 mm). Measurements on each 5-m length were replicated five times per plantation and scheduled harvest.

Figure 1. Schematic view of the biobaler WB-55.

Figure 2. Fixed hammer head.

Figure 3. Biobaler® WB-55 and Fendt™ 818 tractor.

The first harvest took place at the Willow Shade Farm in Godmanchester (Québec) on August 25-26th 2009 (willow only). The second harvest took place at the Agro Énergie farm in Saint-Roch-de-l’Achigan (Québec) on September 1st and 2nd 2009 (willow only). On November 30th 2009, willow and poplar were harvested in Kemptville (Ontario). On December 1st 2009, willow and poplar were harvested in Pickering (Ontario). On December 2nd and 3rd 2009, willow was harvested in Guelph (Ontario). Willow was harvested again at the Agro Énergie farm during the year 2010, on April 12th, June 29th and November 24-25th. Woody crops had leaves in August and September 2009, and in June 2010. At other times, leaves had fallen to the ground and only stems were collected.

2.3. Measurements during and after Harvest

Machine productivity was based on time measured within ±1 s at three steps: harvest, tying, and transition (time between bale ejection and start of a new bale). A typical experimental unit represented a continuous harvest sequence of 20 bales or more (about 400 kg per bale). For each experimental unit, total harvested area was measured. Each bale was measured for diameter and width with a measuring tape (±0.5 cm). It was also weighed with a platform type balance, Cardinal model 205 (0 to 2250 kg, ±0.5 kg). Bale moisture content was determined with wet material collected during harvest. A composite sample of about 1500 g was collected for every four consecutive bales. Samples were placed in paper bags, weighed (±0.1 g), and dried in an oven (Thermo Scientific OV128060, 4100 W) at 103˚C for 72 h. The dry samples were weighed again to estimate moisture content which is expressed on a wet basis (evaporated water mass × 100%/original wet mass of sample).

Diesel fuel consumption was measured after completing a harvest experimental unit (usually at least 20 bales). The fuel tank of the tractor was filled at the beginning of the harvest trial, and again at the end. The fuel mass was converted to volume by assuming a density of 0.8269 kg/liter [12].

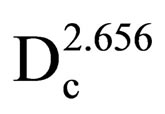

After harvest, two types of loss were measured. The first type of loss was small particles (less than 20 cm) on the ground. These particles were picked up manually and placed in bags. Samples were taken over a length of 1.0 m along a row by the width of a group of rows (e.g. 3.2 m wide for a group of three rows 0.6 m apart plus the distance of 2.0 m from the next group of rows). The second type of loss was composed of long particles, often full length stems that were either cut and left on the ground or uncut and clinging to the stump after the passage of the baler. Over a distance of 40 m, all long particles were counted and the diameter of each stem was measured at the point of cut (or at 0.1 m from the ground for uncut stems). When long particles were not full length stems, a second diameter was measured near the small end of the stem. Empirical equations were used to estimate the mass of these long individual stems (m = 0.104 , where m is wet stem mass in g, Dc is stem diameter at point of cut in mm; m = 0.364 DBH2.514, where DBH is diameter at breast height, 1.35 m above the ground when stem is assumed to be cut at 0.1 m from ground; average ratio Dc/DBH = 1.30; parameters based on experimental data). The estimate of field loss was repeated three times per site and per day of harvest during the first six harvests.

, where m is wet stem mass in g, Dc is stem diameter at point of cut in mm; m = 0.364 DBH2.514, where DBH is diameter at breast height, 1.35 m above the ground when stem is assumed to be cut at 0.1 m from ground; average ratio Dc/DBH = 1.30; parameters based on experimental data). The estimate of field loss was repeated three times per site and per day of harvest during the first six harvests.

2.4. Cost and Statistical Analyses

The cost analysis is based on a method used by the USDA Forest Service [13] and Auburn University [14] for estimating logging equipment cost. This method takes into account operating and ownership costs. The method is adapted to include some particularities of the biobaler. Table 1 lists the major economic assumptions.

Table 1. Basic parameters and assumptions to estimate fixed and variable costs of the tractor and biobaler, with the base case scenario.

The experimental data were analyzed by linear regression. A total of 8 dependent variables were identified: Y1, wet bale mass (kg WM); Y2, wet bale density (kg WM/m³); Y3, dry bale mass (kg DM); Y4, dry bale density (kg DM/m³); Y5, harvest capacity (bales/h); Y6, harvest capacity (t DM/h); Y7, harvest capacity (t WM/h); and Y8, diesel fuel consumption (L/t DM). They were correlated with 8 independent variables: X1, woody crop species (1, willow; 2, poplar; 1.5, mix); X2, average DBH of large stems (DBH ≥ 10 mm), mm; X3, maximum DBH, mm; X4, number of small stems (DBH < 10 mm) per hectare; X5, number of large stems/ha; X6, moisture content (%); X7, presence or absence of leaves (0, absent; 1, present); X8, harvested yield (t DM/ha). The linear regressions were done by step-wise deletion, removing the least significant independent variables successively as long as they were not significant at the p = 0.05 level.

3. Results

3.1. Plantations Characteristics Prior to Harvest

Table 2 shows the main physical properties of woody crops measured just a few hours prior to harvest. Willow plantations had a greater total number of stems (135,000/ha) than poplar plantations (56,000/ha), but average diameter of the large stems (defined as having a DBH > 10 mm) was smaller for willow (17.4 mm) than for poplar (31.2 mm). The largest single diameter stems observed had a DBH of 56 mm in willow and 44 mm in poplar. The variation between sites is explained partly by differences between clones, soil and climate. Some woody crops generate greater number of small stems while others produce a smaller number of bigger stems.

3.2. Bale Mass and Biobaler Harvest Rate in Plantations

Table 3 illustrates the average bale mass, bale density and moisture content. Out of 19 experimental units measured, only three contained poplar, two of which were

Table 2. Plantation characteristics just prior to harvest: number of years of growth (age), average stem diameter at breast height (DBH) of large stems, and number of stems per hectare [small stems are grouped by DBH < 10 mm; large stems, DBH ≥ 10 mm].

Table 3. Number of bales harvested in plantations per experimental unit, average bale mass on a wet matter (WM) basis, moisture content and bale density.

mixed with willow. It is therefore difficult to distinguish the two species in terms of bale mass and density, even though the limited data indicated that polar produced heavier bales than willow (see the statistical analysis below). Overall average bale mass was 427 kg wet matter (WM), with an average moisture content of 48.6% (average DM of 219 kg/bale). Bale density averaged 266 kg WM/m3 or 139 kg DM/m3.

Harvest capacities are shown in Table 4. They ranged from 23 to 48 bales/h with an average of 35 bales/h. The total cycle time to harvest each bale averaged 1 min 47 s (01:47); it was divided on average as 0:59 for filling the bale chamber, 0:36 for tying and 0:12 for ejecting and starting a new cycle. Based on average bale mass and moisture content, the average harvest capacity with the biobaler was therefore 7.69 t DM/h or 15.0 t WM/h. The harvested yields ranged from 10 to 32 t DM/ha, with an average of 19.4 t DM/h (the actual total yield is estimated below by adding losses). Fuel consumption also varied considerably, from 2.1 to 7.0 L/t DM, with an average of 3.9 L/t DM.

Table 5 shows the results of the linear regressions between 8 dependent variables and 8 independent variables to explain variations notably in bales mass, bale density, harvest rate and fuel consumption. According to models Y1 and Y3, bale mass was higher for poplar than for willow, and was also increased in the presence of leaves (62 kg more wet mass, 27 kg more dry mass per bale). Only wet density (Y2) increased as a function of moisture content while dry matter density (Y4) was not affected by any observed independent variables. All three harvest capacities (Y5, Y6, Y7) were affected positively by average stem DBH and harvested yield but negatively by maximum stem DBH. Mass capacity (Y6, Y7) was also affected positively by the presence of leaves, but not bale capacity (Y5). Increased moisture content affected negatively the dry matter harvest capacity (Y6). Finally, variations in fuel consumption were not explained by any of the eight observed independent variables. Other factors, such as soil conditions, wheel slip and operator experience are factors that would likely affect fuel consumption with a relatively novel harvest technology.

3.3. Dry Matter Losses

Table 6 presents estimates of dry matter loss as measured by random samples on six sites or dates. The average total loss observed was 2.33 t DM/ha, with a propor-

Table 4. Harvest capacity in bales per hour and mass of dry matter (DM) per hour, actual harvested yield and tractor fuel consumption during harvest.

Table 5. Linear regressions to predict dependent variables as a function of independent variables observed during harvest in plantations with the biobaler.

Table 6. Random samples of dry matter loss after passage of the biobaler.

tion of 84% from particles on the ground and 16% of long stems (cut or uncut). When these absolute losses were compared to actual harvested yield (18.23 t DM/ha on average), total losses represented on average 11.3% of total yield (20.56 t DM/ha on average). Losses ranged from 5.7% to 20.1%. Some clones were stiffer and more breakable than others, explaining partly some differences in loss.

On the Agro Énergie site harvested on November 24- 25, 2010, no loss estimate was made directly after harvest because of snow fall on the following day. However, in spring 2011, small heaps of wood chips were observed at the same location bales had been ejected. A set of 12 measurements of these heaps in May 2011 indicated that an average 1.97 t DM/ha of loss was due specifically to wood chips falling off the bales at the time of ejection. These small heaps had not been measured in the previous random samples reported in Table 6. At the Agro Énergie Farm on November 24-25, 2010, average harvested yield was 20.1 t DM/ha, so random losses estimated at an average of 11.3% would represent 2.5 t DM/ha. The additional non-random point losses due to wood chips falling off ejected bales (1.97 t DM/ha) would represent an additional 8% of loss with respect to total yield.

3.4. Cost of Operating the Biobaler

Average baling costs are reported in Table 1. The total fixed and operating costs of the biobaler and tractor were estimated on average as $175.41/h, for an average harvest capacity of 35 bales/h (7.7 t DM/h). This is equivalent to $5.01/bale or $22.84/t DM. The cost of harvesting will decrease as baling capacity increases. The impact of baling capacity is illustrated by total cost which is estimated as $18.01/t DM at relatively high capacity (45 bales/h or 9.9 t DM/h) and $31.51/t DM at relatively low capacity (25 bales/h or 5.5 t DM/h).

The cost model also allows simulating the impact of technical changes. For example, if the bale tying mechanism were improved to decrease the twine attachment time by 50% (18 s instead of 35 s), the average capacity would be increased from 7.7 to 8.87 t DM/h and the baling cost would be reduced from $22.84 to $19.78/t DM. This represents a 13% baling cost reduction. It might justify a higher purchase price for an improved and faster tying mechanism.

4. Discussion

The biobaler operated with a considerably higher capacity in plantations (average of 35 bales/h) than in previous reports in natural stands (2 to 26 bales/h in brushland according to [11]; 4 to 9 bales/h in forest understory according to [9]). The higher capacity in plantations is easily explained because of usually well prepared land compared to uneven soil conditions in brush land or forest, and also because of more uniform yield in planted crops. Nonetheless, there were strong variations between plantations in terms of harvest rate (23 to 48 bales/h), and also in terms of unrecovered biomass or losses (6 to 20%). In addition, the biobaler itself caused non-random biomass losses of about 8% in the form of wood chips not contained in the bale at the point of ejection. This latter loss could be reduced by faster tying (therefore causing less abrasion during the tying cycle) and the use of a net wrap instead of twine.

The biobaler handles bales in the form of round bales which may be used in some applications with minimum processing such as combustion of round bales in a boiler [15,16]. However, if it requires further processing to reduce size and produce a mulch, there will be an extra cost to convert the bales into fine particles. An overall assessment of the process should be studied to compare biobaler harvest with direct chipping systems [5].

The biobaler remains a versatile harvest system because it can harvest either natural shrubs or planted SRWC. It is suitable for collecting biomass on small and varied land holdings. Large scale direct chippers appear more suitable for large scale plantations because they avoid a process operation of size reduction (chipping) which may be required in several biomass applications.

5. Conclusions

The biobaler was shown to harvest short rotation woody crops (SRWC), either willow or poplar stems of less than 50 mm diameter at breast height, at an average rate of 35 bales/h, 7.7 t DM/h or 15 t WM/h. It left at random locations on the ground an average of 11% of biomass (either cut particles, cut branches or uncut stems). An additional 8% of non-random losses were small heaps of wood chips left at the point of bale ejection; this latter loss could be reduced by faster tying and the use of net wrap instead of twine for better biomass containment within each bale. The cost of operating the biobaler with a 149 kW tractor averaged $175/h, i.e. $5/bale or $22.84/t DM.

The biobaler is a versatile harvester for SRWC because it can work either in brush land, forest understory or plantations. Its preferred utilization will be in environments where it can harvest diverse woody crops, and where the resulting large round bales may be used for final application as a rough mulch or for combustion in large furnaces needing minimal processing or size reduction.

6. Acknowledgements

The authors thank Natural Resources Canada for its support through the Canadian Biomass Innovation Network. They thank private owners of plantations who provided access for harvesting. They recognize the long term support of Agriculture and Agri-Food Canada for the biomass research program, the Canadian Forest Service for the woody fibre research program, and the Natural Science and Engineering Research Council of Canada for graduate student training.

REFERENCES

- DEFRA, “Best Practice Guidelines for Applicants to Defra’s Energy Crops Scheme. Growing Short Rotation Coppice,” Department for Environment, Food and Rural Affairs, Defra Publications, London.

- D. Styles, F. Thorne and M. B. Jones, “Energy Crops in Ireland: An Economic Comparison of Willow and Miscanthus Production with Conventional Farming Systems,” Biomass and Bioenergy, Vol. 32, No. 2, 2008, pp. 407-421. doi:10.1016/j.biombioe.2007.10.012

- J. Zhang, Q. Sun, J. Zhou, Q. Shan and L. Wu, “Biomass Production of Poplar Plantation Ecosystem in Yangtze River Beach Land,” Energy and Power Engineering, Vol. 1, No. 2, 2009, pp. 81-84. doi:10.4236/epe.2009.12012

- T. A. Volk, L. P. Abrahamson, C. A. Nowak, L. B. Smart, P. J. Tharakan and E. H. White, “The Development of Short-Rotation Willow in the Northeastern United States for Bioenergy and Bioproducts, Agroforestry and Phytoremediation,” Biomass and Bioenergy, Vol. 30, No. 8, 2006, pp. 715-727. doi:10.1016/j.biombioe.2006.03.001

- R. Spinelli, C. Nati and N. Magagnotti, “Using Modified Foragers to Harvest Short-Rotation Poplar Plantations,” Biomass and Bioenergy, Vol. 33, No. 5, 2009, pp. 817- 821. doi:10.1016/j.biombioe.2009.01.001

- P. Savoie, F. Lavoie and L. D’Amours, “Development of Two Headers for a Versatile Woody Brush Harvester Baler,” Applied Engineering in Agriculture, Vol. 25, No. 6, 2009, pp. 811-817.

- F. Lavoie, P. Savoie, L. D’Amours and H. Joannis, “Development and Field Performance of a Willow Cutter Shredder-Baler,” Applied Engineering in Agriculture, Vol. 24, No. 2, 2008, pp. 165-172.

- Anderson Group, “Biobaler WB55,” 2013. http://www.grpanderson.com/

- J. Lorensi do Canto, J. Klepac, B. Rummer, P. Savoie and F. Seixas, “Evaluation of Two Round Baling Systems for Harvesting Understory Biomass,” Biomass and Bioenergy, Vol. 35, No. 5, 2011, pp. 2163-2170. doi:10.1016/j.biombioe.2011.02.006

- W. Schroeder, J. Kort, P. Savoie and F. Preto, “Biomass Harvest from Natural Willow Rings around Prairie Wetlands,” BioEnergy Research, Vol. 2, No. 3, 2009, pp. 99- 105. doi:10.1007/s12155-009-9040-3

- P. Savoie, D. Current, F.-S. Robert and P. L. Hébert, “Harvest of Natural Shrubs with a Biobaler in Various Environments in Québec, Ontario and Minnesota,” Applied Engineering in Agriculture, Vol. 28, No. 6, 2012, pp. 795-801.

- Nebraska Tractor Test Laboratory, “Fendt 818,” 2010. http://tractortestlab.unl.edu/Misc-tests/Fendt818.pdf

- E. S. Miyata, “Determining Fixed and Operating Costs of Logging Equipment,” US Department of Agriculture Forest Service Gen. Tech. Report NC-55, St. Paul, 1980.

- R. W. Brinker, J. Kinard, B. Rummer and B. Lanford, “Machine Rates for Selected Forest Harvesting Machines,” Auburn University, Auburn, 2002.

- Step Trutnov, “Boilers for Burning Whole Bales of Straw,” 2013. http://steptrutnov.cz/

- Farm 2000, “Big bale Boilers,” 2013. http://www.farm2000.co.uk/

NOTES

*Corresponding author.