Engineering

Vol. 3 No. 7 (2011) , Article ID: 6147 , 8 pages DOI:10.4236/eng.2011.37083

Investigation and Optimization of Sn/Gr Lubricants Effects on Cold Extrudability of Fe-TiC Nanocomposite Using Taguchi Robust Design Method

Department of Materials Science and Metallurgical Engineering, Engineering Faculty, Ferdowsi University of Mashhad, Mashhad, Iran

E-mail: zebarjad@um.ac.ir

Received November 7, 2010; revised June 6, 2011; accepted June 15, 2011

Keywords: Extrudability, Fe-TiC, Lubricant, Nanocomposite, Extrudability, Taguchi Robust Design Method

ABSTRACT

The present study deals with the effects of both tin (Sn) and graphite (Gr) powders on the cold extrudability of Fe-TiC nanocomposites as lubricant. The production process includes low-energy ball milling, powder metallurgy and cold direct Extrusion. Due to various factors influencing the extrudability of the Fe-TiC nanocomposites, such as milling time, rate of extrusion, type and content of lubricant and etc, Taguchi robust design method of system optimization was used to determine the approximate contribution percent (% r) of each factor. In order to investigation of Fe-TiC properties, samples with best quality of extrusion were analyzed by XRD and SEM investigations. The results indicate that, sitting the atomic layers of Sn lubricant between Fe and TiC particles leads to decreasing the friction. In this case sliding the particles on each other is easier and a part of the load is applied on lubricant. The results of extrusion of samples indicate that using 2% Sn admixed and die wall graphite lubrication can improve cold extrudability of Fe-TiC nanocomposites.

1. Introduction

Invention and development of advanced materials is a necessary requirement for technological progress. Accordingly, nowadays many researches are performed to minimize the restrictions concerning with their industrial production. Fe-TiC is a unique composite which has been under investigation since 1950 [1]. According to literature survey done by the authors there are many articles focused on the Fe-TiC compsites that can be categorized to 3 groups, synthesis, wear/mechanical properties and hot formability. In the first approach the investigators paid attention to the synthesis of Fe-TiC compsites [1,2]. Another approach focused on the wear and mechanical behavior of Fe-TiC compsites [3,4]. Another viewpoint concentrated on improvement of formability of Fe-TiC composites [5,6]. Until 2001, researches were invented the various synthesis methods of this composites, such as powder metallurgy, mechanical milling etc. But due to defect of limited formability of Fe-TiC composites, investigation was focused on formability improvement of this material [5,6]. In 2007, Peter Zwigl et al., create the super plasticity in ferrotic composite with performance a phase transformation [6]. Werner Theisen et al., performed the hot direct extrusion process on ferrotic composite. The achieved results indicated the anisotropy in microstructure and wear properties of Fe-TiC composites. They proved that both hot and cold working are not suitable for it. This is because due to its high hardness and strength, cold work forming causes to make some severe defects [5]. Because of these limitations, in the recent years, melting methods are utilized as an alternative for powder methods in Fe-TiC production, due to their ability in forming parts with complex shapes [1]. But high energy and specific equipments required for melting method production are still motivations to continue research on overcoming the difficulties of powder methods [1]. In powder metallurgy, the ability of adding powder lubricant to enhance extrudability makes it to be one of the most appropriate methods in forming such composite. To the best of our knowledge, and in spite of importance of role of lubricant on extrudabilty of Fe-TiC composite, the subject has not been under more attention. Thus, the main goal of this study is to study the effects of Sn/Gr lubricants on improvement of cold extrudability of Fe-TiC nanocom-posite.

2. Experimental Method

2.1. Materials

Iron powder with average size of 150 µm and titanium carbide powder with approximate size smaller than 36 nanometers were used as starting material to form Fe-TiC nanocomposite. Besides, Tin powder with average size smaller than 50 µm and graphite powder were used as powder lubricant. Figure 1 show the TEM micrograph taken from nano size titanium carbide powders.

2.2. Sample Preparation

Mixture of Iron, TiC, Tin and Graphite powder were milled by steel balls (10, 12, 15 mm) with ball to powder weight ratio (BPR) 10:1, in a low energy planetary ball mill with 250 rpm. For all of the samples, equal amount of powder (14 gr) were compressed by ZWICK universal machine in a 14.18 mm diameter cylindrical die with 300 MPa stress. This low pressure, avoids high work hardening of powders which makes more pressure required in extrusion step. Besides, high compress pressure leads to lubricant powders driven to porosities, decreasing the lubricant role in particles slip. But the insufficient strength of low pressure compressed powders makes extrusion impossible. So in order to obtain required strength for extrusion, all samples were pre-sintered by a digital oven with Ar atmosphere in temperature 450˚C for 1 hr with warming and cooling rate of 10˚C/min. According to previous studies [7], proper temperature required for sintering of iron-based composites, is in the range of 400˚C to 600˚C. Considering no high strength required and in order to avoid full sintering of powder particles, temperature 450˚C was selected for pre-sinter of samples. The extrusion die was made of heat treated and finished SPK. Area reduction of die was 20% with 8.5˚ semi die angle (Figure 2). Extrusion process was done in two conditions, with and without graphite as die wall lubrication. It was tried that all of the samples lubricated with same conditions. Extruded samples were rated according to their quality and analyzed by Taguchi robust design method of system optimization.

2.3. Main Parameters and Their Levels

In order to investigate the lubricant effect on extrudability of Fe-TiC nanocomposites, parameters and their levels mentioned in Table 1, were selected as Taguchi design factors.

Figure 1. TEM micrograph of TiC nanoparticles used for Fe-TiC nanocom-posite production.

Figure 2. Area reduction and semi die angle used in this research.

Table 1. Controlling factors and their levels.

2.4. Table of Experiment Design

Table 2 illustrates Taguchi orthogonal L16 matrix that considers experiments with 5 factors A, B, C, D, E in which every factor has 4 levels identified in Table 1. Each of the experiments repeated twice and quality of the same samples was very similar.

3. Results and Discussion

3.1. Extrusion without Die Wall Lubrication

In this part of experiment, samples mentioned in Table 2, were extruded without die wall lubric-ation. None of the results were successful and the samples ruptured.

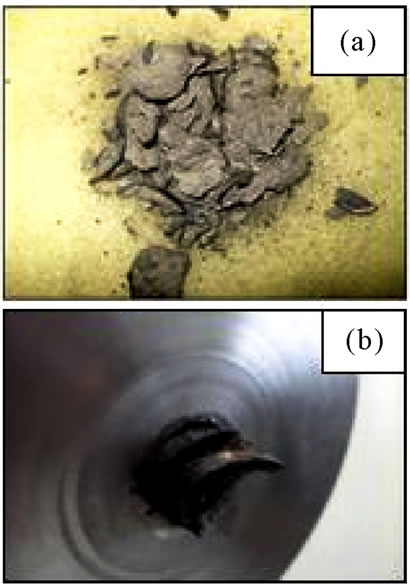

By manually applying graphite with little moisture to the die wall, some of the samples were extruded successfully (Figure 3). In fact moisture enhances graphite

Table 2. Taguchi orthogonal L16 matrix, designed for five 4 level factors used in extrusion of Fe-TiC nanocomposite.

Figure 3. Quality of extruded sample L16-2 (right) and L16-14 (left) (a) and (c) Extruded sample without die wall lubrication (b) and (d) Extruded sample with graphite die wall lubrication.

performances and reduces its shear stress. Due to purity and quality of graphite, it can reduce the friction coefficient in material-die interface up to 0.05 - 0.25 [7,8]. In fact the role of graphite lubricant is friction coefficient (m) reduction up to 0.25 [7,8]. In other words, by reduction of friction coefficient, graphite prevents hydrostatic tension in the center of samples which causes rupture during extrusion [9,10].

3.2. Extrusion with Die Wall Lubrication

In this condition, extrusion of some of the samples was successful. Figure 4 illustrates the Force-Displacement diagram of all samples during extrusion. A comparison of their quality is mentioned in Table 3. Graphite advantage was its proper adhesion to die wall, While Sn in addition to proper adhesion to the die wall, gives desired properties to the nanocomposite (such as sintering temperature decrease by making liquid phase [5]) when it is mixed with nanocomposite powders. Figure 4 illustrates the extruded samples according to their quality respectively and in Figure 5 unextrudable samples are depicted. Letters A, B, etc. … equal to 100, 80, etc. were used to perform a quality rating of samples and 0 referred to ruptured samples.

In order to quantify the samples quality and using Taguchi analyze [6], letter A equal to 100, was referred to best sample and other samples were given a number in comparison with best sample and 0 referred to ruptured samples (Table 3). As the pressure at the maximum point of Force-displacement diagram is equal to required load to begin material flow and outgoing from the die, here it

Table 3. Ranking of quality of extruded samples.

Figure 5. Ruptured samples during extrusion.

is considered maximum load at Force-displacement diagram (Figure 6) as the required force for extrusion. With due attention to unclearing of extrusion forces of some samples, don’t discussion on this case.

3.2.1. Taguchi Experiment Design

By using Taguchi method, experiment with the fewest variance (signal to noise ratio (S/N)) can be recognized and presented as the optimized condition. If optimized parameter needs to be closer to the maximum possible value, the bellow equation can be used to calculate the signal to noise ratio [11-13]:

where yi is the numerical value of the parameter and n is the number of replications per test.

3.2.2. Analysis of Variance

The purpose of the ANOVA is to investigate which process parameters significantly affect on the extrudability

Figure 6. Force-displacement curves of samples extruded with die wall lubricant.

of Fe-TiC nanocomposites. This is accomplished by separating the total variability of the S/N ratios, which is measured by the sum of the squared deviations (SS) from the total mean of the S/N ratio (Sm), into contributions by each process parameter and the error. Equations for calculating the variance for the extrusion quality are presented in this section. These equations can be found in reference no 12, 13, and 14 and have been revised for the current work.

where mi1 and mi2 are the average S/N ratios for level 1 and 2 of factor i, respectively.

DF is the degree of freedom which is the number of experiments minus 1. The degree of freedom for each factor is equal to the number of levels of that factor minus 1 [11-13].

By using Taguchi analyze, it can be optimized the extrusion condition of Fe-TiC nanocomposite containing Sn/Gr lubricant,

and maximized the quality of extrusion products [14]. For this purpose, the average of S/N ratio for each level of all factors are calculated and mentioned in Table 4. In order to better understanding of how optimized level of factors can be recognized, and also finding the most effective factor in optimization of extrusion quality, the average of absolute values of S/N ratio for levels of all factors are depicted in Figure 7. In Figure 7, lines with more slopes represent the more effective factors, and the level which is located above the other levels of a factor is the optimized level of that factor.

From Table 4 and Figure 7, it may be concluded that among investigated factors, milling time is most effective and ramrod rate during extrusion is the least effective factor. Optimized levels of all factors are mentioned in Table 5. Variance analyzes of experiments are mentioned in Table 6 and Figure 8 illustrates approximate

Table 4. Average of S/N ratio for different levels of each factor.

Table 5. Optimized level of factors controlling extrudability of Fe-TiC nano-composite.

Table 6. Variance analyze to improve extrudability of Fe-TiC nanocom-posite.

Figure 7. Schematic presentation of S/N ratio averages for different levels the factors controlling extrudability of Fe-TiC nanocomposite. (Horizontal axis represents different levels and vertical axis represents S/N ratio average for each level).

Figure 8. Circular diagram of approximate contribution percent of each factor and error percent in variance analyze of Fe-TiC extrudability.

contribution percent of each factor and error percent in variance analyze of Fe-TiC extrudability.

3.3. XRD Analyze

In order to investigate the effect of milling time on formation of undesired phases, XRD analyze performed on powder samples L16-12 and L16-16 which had been milled for 15 minutes and 20 hours respectively. These samples contained 4 wt% and 6 wt% of TiC, and 0.5 wt% and 0 wt% of Graphite and 2 wt% Sn respectively. Figure 9 illustrates the XRD results of these samples. The main difference of the samples is related to milling time. As seen an increase in milling time, causes to make the picks of TiC, Fe and Sn smaller and the picks of Fe border. This variations can be referred to the decreasing the crystal plane thickness Due to milling time which leads to amorphization of powder material.

On the other hand, there is no evidence of formation of intermetalic or solid solution compounds of Sn, Graphite and Fe. So rupture of lengthy milled samples is not related to formation of brittle intermetalic or solid solution compounds during ball milling. In order to investigate the role of pre-sintering, XRD analyze was performed on sample L16-8 (milled for 20 hours) before and after pre-sintering. The results of this analyze is depicted in Figures 10 and 11. During milling, increase of surface energy, intensifies the ability of materials in formation of intermetalic or solid solution compounds. In other words, milling leads to decrease required temperature for formation of intermetalic or solid solution compounds [15]. XRD results illustrated in Figures 10 and 11 confirm formation of brittle Fe3C phase after pre-sintering of the sample.

While pre-sintering of samples at 450˚C in Ar atmosphere, Graphite particles having a very high surface energy (caused by milling) interact with Fe matrix. Maximum amount of Sn (and Graphite) in Fe-TiC nanocomposite, changes from 2 wt% (sample L16-4) up to 2.13 wt% (samples L16-13 and L16-16). According to Fe-Sn phase diagram, formation of solid solution of Sn in Fe is possible in the range of 0 to 2.13 wt% of Sn. Although only a few amount of Sn is present, it is difficult to detect by XRD, whether the formation of solid solution has occurred or not. On the other hand, according to Fe-C phase diagram and amount of Graphite in the samples, the brittle phase of Fe3C forms at pre-sinter temperature that can be a good reason for powder hardening and negative effect of graphite on extrudability. Thus, since the pre-sintering is necessary before extrusion, the authors forced to find a method to prevent formation of solid solution and brittle intermetalic between composite matrix and lubricant.

In Figure 12, optical micrograph of best extruded samples, L16-12 are depicted. Two images in the same magnification, from center and edge of the sample are shown for comparison. Grain elongation is not very clear and there is no significant difference in grain elongation intensity of center and edges. In fact, short milling time of mixture of powder composite and lubricants leads to

Figure 9. XRD patterns of L16-12 (lower diagram) and L16-16 (upper diagram) Fe (—), Sn (¡), TiC (*).

Figure 10. XRD patterns of sample L16-4 before pre-sintering Fe(—), Sn(¡), Gr(æ).

Figure 11. XRD patterns of sample L16-4 after pre-sintering at 450˚C Fe (—), Sn (¡), Fe3C (*).

freely sitting of lubricant particles among powder particles. SEM images of this sample confirm that Sn exists among powder particles. Also EDS analyze shown in Figure 13 proves there is a layer of Sn around composite powder particle.

Since the friction is dependent on the magnitude of shear stress at the interface of two particles [8], sitting atomic layers of Sn lubricant (which has low shear stress)

Figure 12. Metallographic images of L16-12 sample. (a) Grain elongation in the center of the sample; (b) grain elongation near edge of the sample.

Figure 13. SEM image of extruded sample L16-12 (5000X) and EDS analyze.

between Fe and TiC particles leads to decrease the friction. In this case particles slide on each other is easier and a part of the load is applied on lubricant [8].

4. Conclusions

The present study deals with the effects of Sn/Gr lubricants on the cold extrudability of Fe-TiC nanocomposites. The results of this study are summarized as bellows:

• Die wall lubrication by Graphite prevents rupture of nanocomposite during extrusion.

• Milling time is the most effective parameter on the quality of extrusion product. Increase in mill-ing time, decreases the degree of crystallinity unlike surface energy of particles. Therefore, possibi-lity of formation of Fe3C brittle phases during pre-sintering was increased.

• Milling mixture of nanocomposite powder with additional 2 wt% of Sn powder for 15 minutes, results in desired extrudability.

Sn lubricant efficiency is obtained by mixing with starting powders, while the graphite is suitable for die wall lubrication due to its high adhesion

5. REFERENCES

- K. Das, T. K. Bandyopadhyay and S. Das, “A Review on the Various Synthesis Route of Tic Reinforced Ferrous Based Composites,” Journal of Materials Science, Vol. 37, No. 18, 2002, pp. 3881-3892. doi:10.1023/A:1019699205003

- K. Feng, Y. Yang, B. Shen and L. Guo, “In Situ Synthesis of Tic/Fe Composites by Reaction Casting,” Materials and Design, Vol. 26, No. 1, 2005, pp. 37-40. doi:10.1016/j.matdes.2004.03.014

- V. K. Rai, R. Srivastava, S. K. Nath and S. Ray, “Wear in Cast Titanium Carbide Reinforced Ferrous Composites under Dry Sliding,” Wear, Vol. 231, No. 2, 1999, pp. 265-271. doi:10.1016/S0043-1648(99)00127-1

- I. W. M. Brown and W. R. Owers, “Fabrication, Microstructure and Properties of Fe-Tic Ceramicmetal Composites,” Current Applied Physics, Vol. 4, No. 2-4, 2004, pp. 171-174. doi:10.1016/j.cap.2003.11.001

- W. Theisen and M. Karlsohn, “Hot Direct Extrusion—A Novel Method to Produce Abrasion-Resistant Metal-Matrix Composites,” Wear, Vol. 263, No. 7-12, 2007, pp. 896-904.

- P. Zwigl and D. C. Dunand, “Transformation Superplasticity of Iron and Fe/TiC Metal Matrix Composites,” Metallurgical and Materials Transactions A, Vol. 29, No. 2, 2007, pp. 565-575. doi:10.1007/s11661-998-0138-6

- A. Simchi, “Effects of Lubrication Procedure on the Consolidation, Sintering and Microstructural Features of Powder Compacts,” Materials & Design, Vol. 24, No. 8, 2003, pp. 585-594. doi:10.1016/S0261-3069(03)00155-9

- A. R. Lansdown, “Lubrication: A Practical Guide to Lubricant Selection,” Material Engineering Practice Series, Pergamon, 1982, pp. 126-154.

- P. J. Blau, “Friction Science and Technology,” Oak Ridge National Laboratory, Oak Ridge, 2008, p. 126. doi:10.1201/9781420054101

- G. E. Dieter, H. A. Kuhn and S. L. Semiatin, “Handbook of Workability and Process Design,” American Society for Metals, Materials Park, 2003, pp. 27-29, 54-60, 291- 321.

- R. Roy, “A Primer on the Taguchi Method,” Van Nostrand Reinhold, New York, 1990.

- T. Mori, “The New Experimental Design, Taguchi’s Approach to Quality Engineering,” 1st Editon, ASI Press, Dearborn, 1990.

- A. Bendell, J. Disney and W. A. Pridmore, “Taguchi Methods: Applications in World Industry,” IFS Publications, Kempston, 1989.

- K. D. Kim, D. W. Choi, Y. H. Choa and H. T. Kim, “Optimization of Parameters for the Synthesis of Zinc Oxide Nanoparticles by Taguchi Robust Design Method,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 311, No. 1-3, 2007, pp. 170-173. doi:10.1016/j.colsurfa.2007.06.017

- C. C. Koch, “Mechanical Milling and Alloying,” Material Science and Technologhy, Vol. 15, 2001, pp. 193- 245.