A Preliminary Study and Characterization of Nasir Abad Hunza Marble Deposit Gilgit Baltistan ()

1. Introduction

Gilgit-Baltistan is in the northwest of Pakistan on the junction of Himalayan, Hindu Kush and Karakorum Mountain ranges. It is part of the Himalayan Mountain range, which has an exceptionally mountainous topography; it is the eastern portion of the region and consists of five well-defined ranges, aligned in a north-west direction and convex to the south. The diverse geology of the region has naturally endowed vast marble deposits.

Marble is a rough crystalline rock derived from limestone or Dolomite: pure white marble is mainly composed of calcite minerals. Marble is a metamorphosed form of limestone or dolomite. Heat and pressure are the primary agents that lead to the metamorphism of calcium carbonate (CaCO3) and magnesium carbonate (MgCO3) sedimentary rock in the process of converting it to marble. Depending upon the mineralogical composition of a region, marble could be composed of calcite or Dolomite. Dolomitic marble is relatively more resistant to acid attack than calcite marble. The color of marble ranges from the brilliant white of calcite to black, including blue-grey, red, yellow and green, depending upon the mineral composition [Baker (2017)]. Proper characterization of Dolomitic Marble and granite deposits is essential for its extraction, processing and marketing.

2. Literature Review

The main purpose of this research is to determine the physical, chemical and mechanical properties of the Nasir Abad Hunza marble deposit for its proper characterization and its use as a decorative stone. According to the Geological Survey of Pakistan (G.S.P.), Nasir Abad Hunza dolomitic marble deposit belongs to CHALT SCHIST and relates to Darkot Group [1] . The age of the CHILT SCHIST is Lower Cretaceous, but the Darkot group is Permian and carboniferous age. In 2018 the U.D.H.R.U.H., SOUTHERN JORDAN marble was examined by Mansour Shqiarat et al.; with the help of X-ray fluorescence (XRF) they used EDX-7000/8000 model for their analysis to determine their chemical composition, mostly they detected CaO, which was 98%, and it was calcite marble [2] . Abu Jaber et al. (2012) identified the possible sources of marble in Petra; it was most likely from the quarries of Thasos, Penteli. Based on the results discussed, the Greek marble is most likely the source of marble in the Udhruh site. Petra was a camper city for many centuries, and a wide and good variety of marble was imported from all over the ancient world [3] .

This research will also provide the foundation for the characterization of similar deposits in the Gilgit-Baltistan region that could play an essential role in the socio-economic uplift of this region.

3. Basic Concept

Marble is derived from limestone or Dolomite and its rough crystal stone. Different verities are found in marble; some are pure white marble which is mainly composed of calcite minerals. Marble is a metamorphic rock that can be found by the process of metamorphism or transition from limestone (Husaini et al. [4] ). Two major agents are applied: temperature and pressure, or dolomite produced by endogenous forces, which causes recrystallization of these rocks and produce new form foliation and not foliation.

The other processes of heating with amino catalyst create resin produced from polymerization. These resins are used widely in the chemistry, mechanical and civil industries as coating paints, adhesives, cord printing and moulded objects. The most produced epoxy resin is from bisphenol A and epihalohydrin. Composite materials are composed by a mixture of two or more materials with different physical and chemical properties and produce a new material with different properties with its constituent materials.

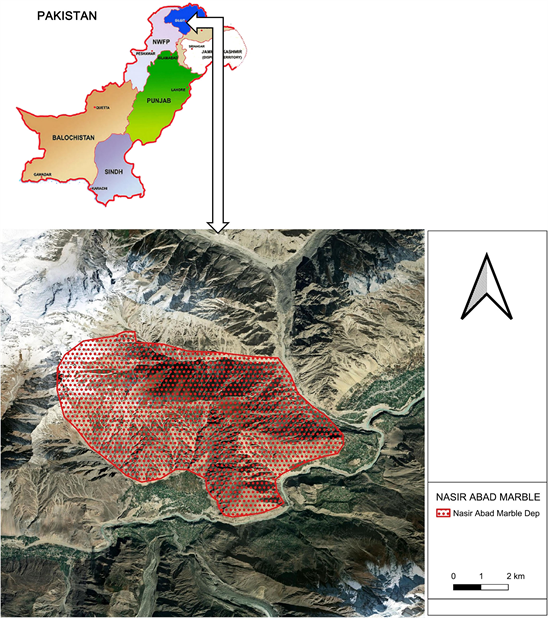

4. Site Location

A deposit of dolomitic marble and calcite schist is exposed near the Nasir Abad Bridge on Karakoram Highway (K.K.H.) District Hunza in north of Pakistan.

5. Sample Collection, Preparation and Analysis

Channel sampling method was placed during the field to pick both Samples. It was collected from two different access directions of the deposit. The first access point is from North-West Direction; the second one is from South-West Direction (Figure 1).

The Samples which were collected from the North-West direction are Grey in color. The second one, picked up from West-South, is white and milky in color.

The samples differ in grain size also. The grey one is coarse-grained while the white one is fine-grained. Previously active mining faces were also sampled. These raw samples were collected through a random and channel sampling method. The location of sampled points was recorded by using digital G.P.S. Currently, no mining activity for Marble extraction is in progress within this deposit. A total of four raw Marble samples/boulders were collected from the said deposit. For convenience, the codes, namely S1, S2, S3 and S4 will refer to these raw samples in subsequent sections.

5.1. Sample Preparation

Core samples were extracted from the raw marble boulders through the core drilling machine in the rock mechanics laboratory in the Department of Mining Engineering Karakoram International University Gilgit. The samples used for the study are AX-size (43 mm dia) cylindrical specimens. To attain the required length-to-dia ratio of core sample as per ASTM standard for different tests, the samples were cut to size by a core cutting machine. These samples were subjected to the following tests to complete the preliminary characterization process of the deposit under study (Figure 2).

5.2. Hardness

Hardness is the resistance of a material to scratching. The hardness of rocks is determined by using Mohr’s hardness scale range from 1 to 10. Talc is the softest material on Mohr’s hardness scale, having a value of 1, while diamond is the hardest material with its value reaching 10. To determine the hardness of specimens, hold it against the table, place the standard specimen against it, press

![]()

Figure 2. Extracted core sample from raw marble boulder.

firmly with determination, then holding pressure slowly drag the standard specimen across the surface of the specimen under the trail. The harder scratcher will scratch the specimen while the softer one will not.

5.3. Density

The ratio of mass to volume of a material is called its density. The following formula is used for the determination of density:

(1)

where P density, m Mass is denoted by m represents, and V. Density V denotes volume. Density denotes volume is expressed as kilograms per cubic meter (kg/m3) or pounds per cubic foot (lb/ft3). ASTM C97 standard for density measurement was followed.

5.4. Slake Durability Test

Slack durability test measures the resistance of rock samples to weathering. The Standard Operating Procedure (S.O.P.) for its determination is based on ASTM D 4644-87 (Reapproved 1992) Standard Test Method for Slake Durability of Shale’s and Similar Weak Rocks. This standard provides technical guidance and procedures employed in this study to measure the slake durability index of the samples. To measure this index, two sample sets, each comprised of ten pieces of rock and each piece weighing 40 to 60 gm are placed in oven at 105 C for 10 minutes to remove any moisture. These dried samples are then weighed and recorded as W1. These sample sets are then placed in the drums of the slake durability apparatus, filled with water to the required level. The sample is revolved around for 10 minutes. The samples are again placed in an oven, and dry weight of the samples is recorded as W2. The slake durability index is calculated as:

(2)

5.5. Rock Water Absorption

Rock water absorption is the amount of water absorbed by a specimen under specified conditions. Factors affecting water absorption include temperature, length of the specimen and its environments [5] . The water absorption test is performed as per ASTM D570 standard. Following the instruction of the mentioned standard, the sample is first placed in an oven for a specified time and temperature and then weighed to get the initial dry weight of the sample. The sample is then put in water at 23 C for 24 hours. It is then dried with a lint free cloth and weighed again to get the final weight. The initial weight is subtracted from the final weight to determine the water absorption of the rock sample under study.

5.6. Compressive Strength

Compressive strength is a measure of resistance to crushing loads. The compressive strength is the maximum load per unit area that a material can bear without crushing. A higher compressive strength indicates that the material can withstand a higher crushing load. The compressive strength of marble ranges typically from 30 MPa to 150 MPa, and in the case of granite, it ranges from 130 to 200. The compressive strength of marble is determined as per ASTM C170 standard.

5.7. X-Ray Fluorescence (XRF)

X-ray fluorescence (XRF) Testing machine WD-XRF-1800. It is the analyzer which can be used for the analyzing of elements in the specimen that emit their characteristic X-ray spectra. The wavelengths of the spectral lines may be used to identify the element and the intensity of the line determines the concentration of the element.

The XRF technique is different from the X-ray diffraction method in that the elements rather than the compounds are identified, estimated, and accomplished easily. It is generally used for determining the chemical composition of powdered materials.

XRF analysis of the marble sample is carried out to determine the chemical composition of powdered materials. The elements within a specimen are identified by analyzing X-ray spectra. The wavelengths of the spectral lines may be used to identify the element and the intensity of the line determines the concentration of the element. XRF usually is used for determining the chemical composition of powdered materials [6] . The analysis of the marble sample is carried out as per ASTM-D5381 standard.

5.8. Ultrasonic Pulse Velocity Test (U.P.V.)

Ultrasonic Pulse velocity is an in-situ non-destructive test used to check the quality of the concrete and natural rocks. In this test, the strength and quality of the rock are assessed by measuring the velocity of an ultrasonic pulse passing through a concrete structure or natural rock formation. The higher velocity indicates good quality and the continuity of the rock. While the slower velocity indicates the low quality of the rock, it means that the rock has many cracks and voids. ASTM D-2845 standard is followed for performing the U.P.V. test of the marble sample. The following formula is used for determining pulse velocity.

(3)

6. Results and Analysis

6.1. Chemical Properties of Marble

The chemical compositions of marble samples were determined through X-ray fluorescence analysis (XRF). The chemical compositions of the four marble samples are shown in Table 1.

The results of X-ray fluorescence (XRF) show some chemical concentrations present in the tests samples. Mostly CaO is high in their concentration up to 64% and MgO were 34%, which correlates with the standard value for calcite marble and dolomitic marble.

6.2. XRF Graphics Result

The following graphs show the original XRF results for both Samples (1 to 4).

Graph 3 represents sample 1 result, graph 4 represents sample 2 result, graph 5 represents sample 3 result and graph 6 represents sample 4 result.

The individual results of chemical composition per sample are discussed in Table 1 and Figures 3-6.

6.3. Physical Properties—Hardness, Density, Water Absorption, & Slake Durability Test

The physical properties of marble samples like specific gravity, density, hardness, water absorption, etc. were determined following the previously mentioned

![]()

Table 1. Chemical composition of Nasir abad hunza marble samples.

ASTM standards. Through experiments, the hardness of the samples was found to range from 3.5 to 5 on Moh’s Hardness scale, while the average density of the samples was found to be around 2.67 gm/ml. A total of 8 samples were used to measure the water abortion property of samples. The result of the experiment revealed that the water absorption of the samples is around 0.115%. The water absorption of marble understudy is lower than the standard value of hardness,

which is 0.1%. The slake durability of the marble specimen was carried out, and 99.6% of the specimen were recovered after the test. The loss comes out to be less than 0.5% which is the standard value for marble. This means that the marble under study is highly durable. The comparison of the physical properties of marble with ASTM standard values is given in 2. The results show that the physical properties of Hunza marble satisfies the minimum ASTM requirements.

Comparison of the physical properties of Nasir Abad Hunza Marble with ASTM Standard of Marble and Dolomite

1) The result of hardness is 3.5 to 5 Mohr’s scale but in ASTM standard for dolomitic marble is 3.5 to 4 Mohr’s and Calcite Marble is 3 to 5 Mohr’s.

2) The result of Specific Gravity/Density is 2.52 to 2.7 but in ASTM standard for dolomitic marble is 2.8 to 2.9 and Calcite Marble ASTM (C97) is 2.4% to 2.7%.

3) The result of water Absorption is 0.1% but in ASTM the standard for dolomitic marble is 0.1% and Calcite Marble ASTM (C97) is 0.2%.

4) The result of Slake Durability is 0.35% but in ASTM standard for dolomitic marble is 0.4% and Calcite Marble is 1%.

6.4. Ultrasonic Pulse Velocity Test (U.P.V.)

The U.P.V. tests were conducted to check the quality of rock samples. Ultrasonic pulse velocity tester (58-E4800) was used for this purpose. U.P.V. tests performed on different marble core samples are given in Table 3. The comparison of average values U.P.V. of samples with standard values confirms the quality of the marble deposit under study (Tables 2-4).

![]()

Table 2. Comparison of ultrasonic pulse velocity of Nasir abad hunza marble with standard values.

![]()

Table 3. UCS of Nasir Abad Hunza marble with Standard values.

![]()

Table 4. Results of uniaxial compressive strength of Hunza marble.

6.5. Mechanical Properties

The uniaxial compressive strength of Hunza marble, was determined with the help of Universal Testing Machine (UTM), following the ASTM standard mentioned in section 5.6. Twelve (12) core samples retrieved from (4) dolomitic marble boulders were used for this purpose. The results are given in reveal that the sample under study shows variation in their strength range. This suggests U.C.S. based partitioning of the deposit under study for its industrial use.

Dolomite Marble has the least standard value is 81 ± 14.0 MPa U.C.S. test [7] .

7. Conclusion and Recommendations

7.1. Conclusion

This paper shares the results of a preliminary study to characterize Nasir Abad Hunza marble deposit. This deposit is commonly believed to be of calcite origin, but the results show that the said deposit is dolomitic. Comparing different physical, chemical and mechanical properties determined through lab experiments with the standard published results confirms this claim. The chemical composition determined through XRF technique further endorses this claim. A certain level of variance was observed when it came to the mechanical properties of the deposit. The deposit is comprised of marble of two different colors i.e., Grey, and white. White dolomitic marble showed relatively higher strength in comparison to grey marble. This could be the result of incomplete crystallization and metamorphism. The samples of the deposit exhibit water absorption with values like dolomitic marble.

7.2. Recommendation

Initial results of this preliminary study suggest further investigations in the following fields:

➢ Proper lithological mapping of the Nasir Abad Hunza Dolomitic Marble deposit is suggested for its uses in the construction industry.

➢ Detailed geological and economical investigation is required for proper exploitation of the said deposit.

➢ Further studies are recommended to determine properties like thermal expansion and conductivity to characterize the said deposit properly.