S. S. HAVALDAR ET AL.

654

load in thickness (T) direction and shear load in longitu-

dinal (L) and width (W) directions. The material proper-

ties such as elastic moduli and strengths are various in

different directions, and even the compressive and tensile

properties are different in the thickness-direction, pri-

marily due to the initial deflection of cell walls. Vibra-

tion frequencies and mode shapes of honeycomb sand-

wich panels with various structural parameters were

studied by Qunli Liu and Yi Zhao [11] using computa-

tional and experimental methods. Two computational

models were used to predict the mode shapes and fre-

quencies of honeycomb sandwich panels. Plate elements

were used for honeycomb cell walls to reflect the geo-

metric nature of the hexagonal cells. The quantitative

effect of the anisotropic core on the vibration properties

of the sandwich panels were studied and presented.

Most studies in the literature are related to one of the

attributes (high strength/weight or increased energy ab-

sorption) mentioned above. With regard to the develop-

ment of a honeycomb panels, one issue that has been

overlooked is the scaling of honeycomb properties with

respect to cell size. The variation in cell size may have a

large influence on the dynamic properties of honeycomb

panels. The current paper expands upon this study. The

results from the experimental program will be presented

and discussed. The theoretical literature available [12] on

sandwich panels in evaluating fundamental frequency

with a non-dimensional parameter will also be discussed

in this work. Of interest in this study is to understand the

effect of cell size on the fundamental frequency of hon-

eycomb panels.

2. Experimental Techniques

2.1. Fabrication of Honeycomb Panels

FRP honeycomb sandwich panels have been fabricated

through vacuum bag molding technique, which uses the

vacuum to eliminate the entrapped air and excess resin.

The adhesive used is epoxy resin LY 556 mixed with

hardener HY 951. The resin and hardener is mixed in the

weight ratio of 10:1. To maintain optimum strength of

the matrix, the ideal resin to glass ratio is found to be

35:65. The mold used is a “hexagonally machined split

molding tool” made of chromium plated mild steel. After

ensuring the surface is clean and free from foreign parti-

cles, a coat of release agent is applied. A coat of resin

mixture is then applied on the molding surface and the

plain weave glass “E” fabric is impregnated against the

first half of molding tool surface, by ensuring thorough

wetting of glass cloth. Subsequently the hexagonal man-

drel is placed in the respective slots by pushing the glass

cloth down into the half hexagonal slot of the molding

tool (Figure 1). Pressure is applied to the wet laid-up

laminate in order to improve its consolidation. This is

achieved by sealing the wet laid up laminate with a per-

forated plastic film and placing an absorbent over the

perforated plastic film. Above this, a film is placed and

sealed which constitutes vacuum bagging process. At one

corner of the bag, a port for vacuum is arranged and sub-

jected to a pressure of 450 - 500 mm Hg is applied for

120 minutes to consolidate and to increase the inter

laminar shear strength of layers.

2.2. Specimen Details

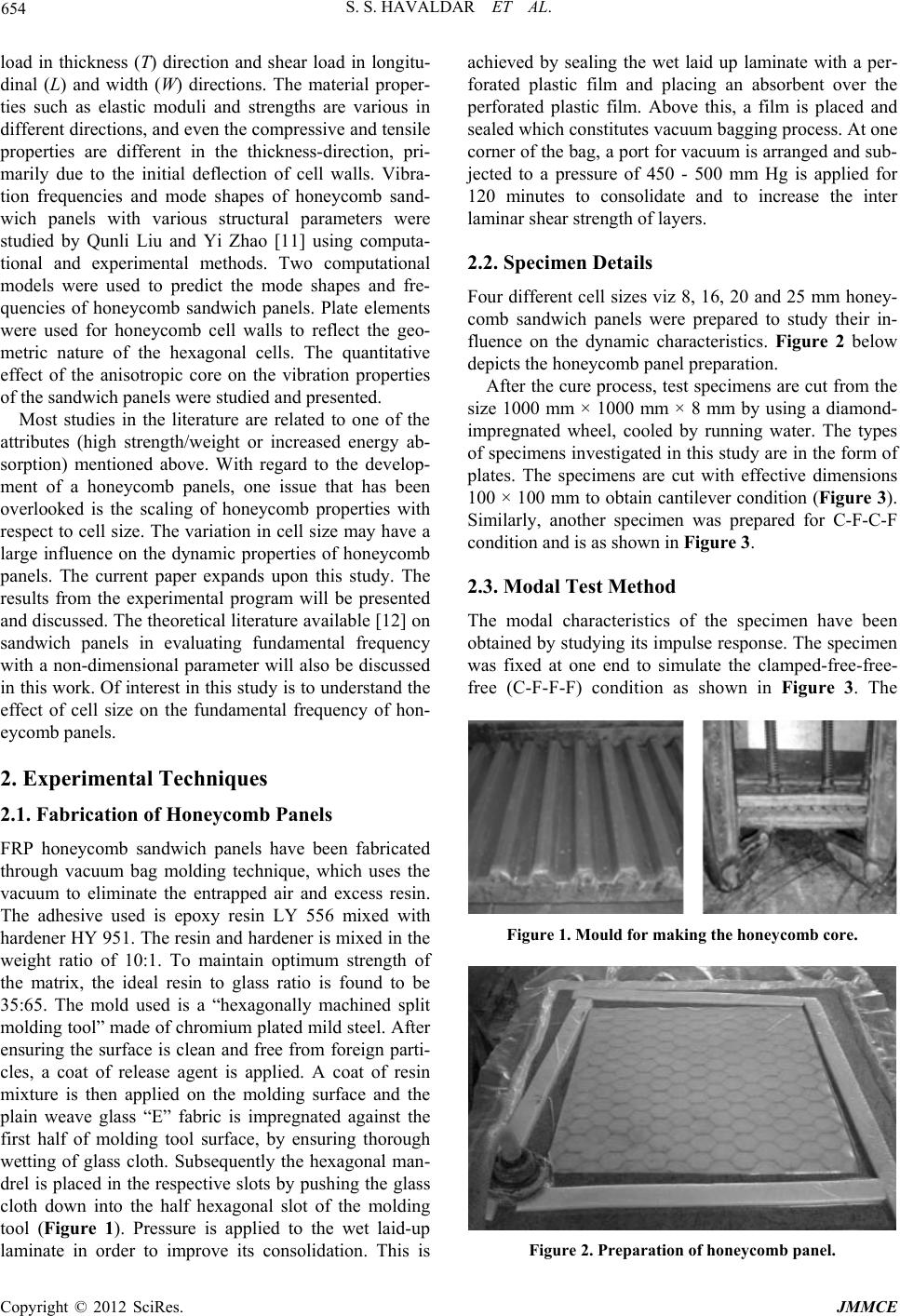

Four different cell sizes viz 8, 16, 20 and 25 mm honey-

comb sandwich panels were prepared to study their in-

fluence on the dynamic characteristics. Figure 2 below

depicts the honeycomb panel preparation.

After the cure process, test specimens are cut from the

size 1000 mm × 1000 mm × 8 mm by using a diamond-

impregnated wheel, cooled by running water. The types

of specimens investigated in this study are in the form of

plates. The specimens are cut with effective dimensions

100 × 100 mm to obtain cantilever condition (Figure 3).

Similarly, another specimen was prepared for C-F-C-F

condition and is as shown in Figure 3.

2.3. Modal Test Method

The modal characteristics of the specimen have been

obtained by studying its impulse response. The specimen

was fixed at one end to simulate the clamped-free-free-

free (C-F-F-F) condition as shown in Figure 3. The

Figure 1. Mould for making the honeycomb core.

Figure 2. Preparation of honeycomb panel.

Copyright © 2012 SciRes. JMMCE