1. Introduction

The process of mechanical alloying (MA) can be used to produce alloys that are difficult or impossible to be produced by conventional melting and casting techniques. MA is a process of repeated fracturing and cold welding of a metal powder mixed with ceramic particulates in a high energy ball mill, HEBM. Therefore MA has received increased attention due to its potential for the fabrication of dispersion strengthened alloys, for the production of alloys with very even element distribution and fine structure and of alloys with amorphous structure [1,2].

Metal aluminium alloy powders from 2000x, 6000x and 7000x series were used as a metal matrix, while oxides, carbides or intermetallic compounds with different sizes were as ceramic particulates [3-6]. It has been confirmed that nano metric scale particles even at lower volume fraction provide better reinforcements than micrometric scale particles for their more effective contribution to the Orowan strengthening mechanism [7-9].

The MA processed powder mixtures can be consolidated later during final processing by hot or cold pressing, extrusion, rolling and heat treatment [10].

The main aim of this work is to investigate the strengthening effect of mechanical alloying on two aluminium alloys with nano and micro size ceramic particles, via microhardness measurements on the new metal matrix composites. During MA considerable cold plastic deformation take place which creates workhardening of the metal matrix powder. A post-MA recrystalisation was applied in this work to eliminate its contribution to the particulate dispersion strengthening effect. It has been reported that the MA powders Oxide Dispersion Strengthened Superalloys recrystallise at exceptionally high homologous temperatures, around 0.9 of the absolute melting temperature (TM). This contrasts with 0.5 - 0.6 TM in ordinary metal forming processes of similar metallic alloys. Strangely enough, the mechanically alloyed metals contain more stored energy than conventionally cold processed metals which recrystallise at lower temperatures [11]. The recrystallization temperature applied in this study was 0.85 TM.

It was established that measuring the hardness of MA mixtures with low load gives reliable information about the strengthening effect achieved [12]

The metal matrix powders used in this study are of cast A356 and wrought 7075 aluminium alloy compositions.

2. Experimental Procedures

The starting materials were powder of aluminium alloys A356 and 7075. The powder particle shapes were spherical and their sizes were 45 - 90 µm. Two different ceramic particulates were mixed with these powders as follows:

• Aluminium oxide, Al2O3 , average particle size 70 nm and 180 nm, respectively, purity 99.99%;

• Silicon carbide, SiC, average particle size 5 µm, purity 99.5%.

The mixtures of ceramic particulates with metal powders are given in a volume percentage.

The studied mixtures were recrystallised after MA at 480˚C for 60 minutes.

The strengthening effect on the metal matrix has been evaluated by measurement of the micro hardness of the mechanically alloyed 7075, respectively A356 particles at 10 g load. Hardness has been measured also after annealing of the milled powder, which eliminates the effect of work hardening achieved during milling process. A “Future Tech” Microhardness tester FM-700 was used.

2.1. Mechanical Alloying with HEBM Retsch 40

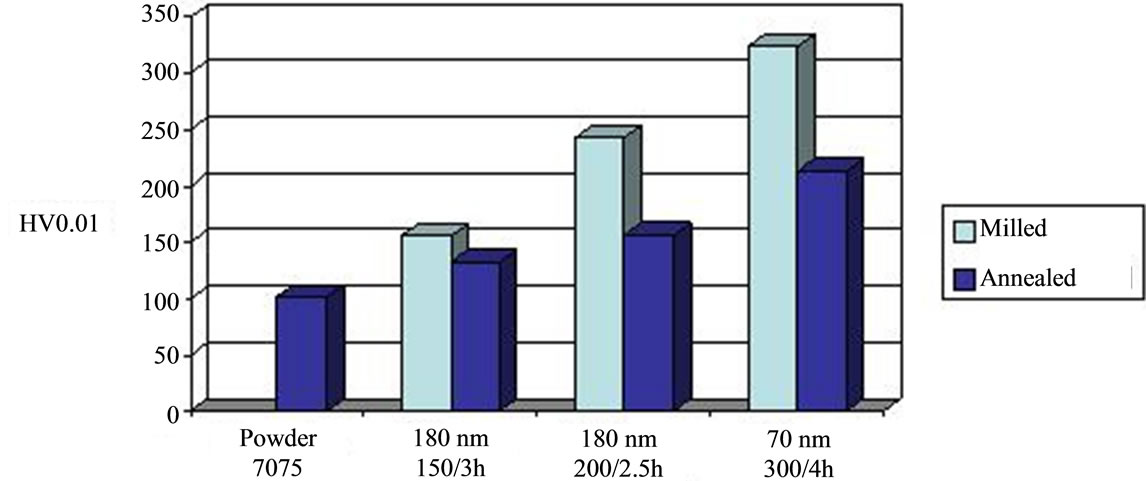

Metal powder 7075 sizes 45 - 90 µm have been mixed with ceramic particulate Al2O3, sizes 180 nm or 70 nm respectively and then processed with High Energy Ball Mill, Retsch 400/2. Tungsten carbide 250 ml vial and 10 mm balls were used. The balls/powder mass ratio was 10:1. Stearic acid of 1.5 weight% was added as process control agent (PCA). No protective gas has been applied into the vial of the mills. The applied process parameters and microhardness results are given in Table 1 and Figure 1. The numbers in bold are the mean values, while those in brackets represent the work hardening contribution in percentage to the total hardness. These indications are also valid for results presented in Tables 2 and 3.

The micro hardness of 7075 metal powder grains before milling was 101 HV0.01.

2.2. Mechanical Alloying with HEBM High Energy Ball ZOZ Simolyer CM1

A horizontal attritor mill with stainless steel 250 ml vial and 4.8 mm balls were used. The balls/powder mass ratio was 20:1. Metal powder A356, has been mixed with ceramic particulates Al2O3, sizes 180 nm and then proc-

Table 1. Microhardness of two different mechanically alloyed powder mixtures after milling and subsequent annealing.

Table 2. Microhardness of mechanically alloyed 50% 180 nm Al2O3 and 50% 45 - 90 µm A356 powder mixtures after milling with different processing parameters and after subsequent annealing.

Figure 1. Microhardness of mechanically alloyed mixture 45 - 90 µm powder 7075 with 180 nm, respectively 70 nm of Al2O3 milled with HEBM Retsch 400.

essed with High Energy Ball ZOZ Simolyer CM1. PCA of 1.5 weight % stearic acid was added to the mixture. No protective gas has been applied into the vial of the mills. The applied process parameters and microhardness are given in Table 2 and Figure 2. The micro hardness of non milled A356 metal powder grains was 102 HV0.01.

Two other mixtures were prepared by mixing of ceramic particulates SiC, average particle 5 µm with powder A356 and powder 7075 respectively. The two mixtures were processed, as mentioned above. The applied milling parameters and microhardness results are given in the Table 3.

3. Results and Discussion

3.1. Hardness

The results achieved by hardness measurements after annealing of mechanical alloyed aluminium alloy powder showed a considerable strengthening effect with respect to the virgin powder. It is more visible with reducing the

Figure 2. Microhardness of mechanically alloyed mixture 50% 45 - 90 µm A356 powder with 50% 180 nm Al2O3 powder milled with HEBM ZOZ Simoloyer CM1.

Figure 3. Microhardness of mechanically alloyed mixture 20% 5 µm SiC with 80% 45 - 90 µm A356 powder, milled with HEBM Simoloyer CM1.

Table 3. Microhardness of mechanically alloyed powder mixture 20% 5 [µm] SiC with A356 and 7075 metal powders respectively, after milling and after subsequent annealing.

grain sizes of the particulates. Thus the hardness of 7075 powder increase from 102 HV0.01 to 156 HV0.01 after alloying with 20% 180 nm Al2O3 or 52%. When particulates are 70 nm the hardness of annealed powder reaches HV0.01 = 213, which is 210% higher than the hardness of un-alloyed powder particles (Table 1). This value is as high as the hardness of this alloy in wrought condition and heat-treated to T6 condition. The strengthening of a mixture of 50% A356 powder after MA with 50% 180 nm Al2O3 reaches 318% (Table 2).

There is also a strengthening effect after MA of this aluminium powder with bigger particulates. The mixture 20% 5 µm SiC and 80% 7075 powder after MA and annealing posses 143 HV0.01, which a 40% increase (Table 3).

When in the same mixture metal powder is A356, the hardness after a moderate milling and annealing is 125 HV0.01, which is the maximum value for this alloy after T6 heat treatment (Table 3).

3.2. Microstructure

The milling of a metal powder and ceramic particles mixture results in oval metal grains, 1 - 3 mm size, with embedded particulate Al2O3 or SiC respectively (Figures 4 and 5). The alloying process progresses by increasing the milling time and revolution of the milling balls until it reaches a uniform distribution into the grain base metal, 7075 or 356 respectively. These MA parameters are considered to be the optimal ones.

The microstructure of MA metal powders was investigated with optical microscope LEICA MZ16A (OM) and scanning electron microscopy FESEM LEO1525 (SEM). The samples were prepared by mixing of MA powder with powder resign and then moulded into 30 mm disks at 150˚C. The samples were processed through

Figure 4, Powder 7075, 45 - 90 µm, mixed with 20% 180 nm Al2O3 and milled at 200 rpm for 2.5 hours, ZOZ HEBM, HV0.01 = 242 (156), OM 100x.

standard metallographic technique of grinding and polishing. No etching of the microstructure was applied.

The OM and SEM microstructures of MA 7075 powder with nano particulate Al2O3 are shown in Figures 4 to 9. The mixture composition, milling process parameters and hardness after MA and annealing (in brackets) are given.

Optical metallography and SEM proved that the applied parameters of MA of powder 7075 alloy with 180 nm Al2O3 give uniform distribution of these particulates in 7075 metal grains, which was found with OM, (Figure 4, 6) and confirmed with SEM, (Figure 8). A similar distribution of 70 nm Al2O3 in the same metal matrix is shown in Figure 5 and Figure 7, while the SEM investigation proved that, in fact, they are 1 - 3 µm oval areas of highly concentrated particulates (Figure 9). This result is probably due to the more severe milling parameters for these finer size particles. Despite this a considerable strengthening effect was achieved even for this MMC (Table 1, Figure 1).

Figure 5, Powder 7075, 45 - 90 µm, mixed with 20% 70 nm Al2O3 and milled at 300 rpm for 4 hours RETCH HEBM, HV0.1 = 323 (213), OM 100x.

4. Conclusions

1) Production of aluminium matrix composites were successfully realised through milling of a metal / ceramic powders mixture with vertical HEBM Retsch-400 and horizontal attritor ZOZ Simoloyer CM1 high energy ball mills.

2) It was found that microhardness measurement of the milled metal particles represent very well the strengthening effect of mechanical alloying process.

3) A large amount of work hardening is involved into microhardness test, results vary from 7% to 35%, depending on the amount of particulates and milling parameters.

4) Application of annealing at a 0.85 homological temperature for 60 min considerably eliminates the effects of work hardening.

5) The hardness of MA mixtures, metal powder and ceramic particles, measured after annealing could be increased up to 300% mainly due to the Orowan strengthening mechanism, depending on amount of the alloyed particulates.

6) The method for evaluation of strengthening effect of ceramic particulates on the metal matrix alloy in this work can be applied for a preliminary test of composition and expected mechanical properties selection of new Metal Matrix Composites, manufactured by casting, extrusion, rolling and forging.